Product data

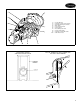

23XL Refrigeration Cycle

The compressor continuously draws

refrigerant vapor from the cooler at a

rate determined by the position of

the capacity control slide valve. This

compressor suction reduces the

pressure in the cooler and causes the

remaining refrigerant to boil vigor-

ously at a low temperature (typically

38 to 42 F [3 to 6 C]).

The energy required for boiling is

obtained as heat from the water (or

brine) flowing through the cooler

tubes. With heat removed, the chilled

water (brine) can then be used for

air conditioning or for process

cooling.

After removing heat from the water

(brine), the refrigerant vapor passes

through the compressor. Compression

adds more energy to the refrigerant,

raising its temperature upon discharge

(typically 75 to 95 F [24 to 35 C]) to

a level above that of the water flowing

through the condenser tubes. This

relatively cool condensing water

removes some of the heat from the

vapor, causing it to condense into

a liquid.

The liquid refrigerant passes

through orifices into the FLASC

(FLAsh SubCooler) chamber. Since

the FLASC chamber is at a lower

pressure, part of the liquid refrigerant

flashes to vapor, thereby cooling the

remaining liquid. The FLASC vapor is

recondensed on the tubes which

carry the entering condenser water.

The liquid then passes through a float-

type metering device before return-

ing to the cooler. This float device

maintains a liquid seal to eliminate

inefficient vapor bypass from the

FLASC chamber to the cooler.

On certain models, an economizer

is installed between the cooler and

condenser. With these models, the

float valve meters liquid refrigerant

into the economizer instead of the

cooler. Pressure in this chamber is

intermediate between condenser and

cooler pressures. At this lower

pressure, some of the liquid refriger-

ant flashes to vapor, cooling the

remaining refrigerant. The vapor re-

turns directly to the compressor where

it mixes with vapor from the cooler

at an intermediate point of compres-

sion. This provides an increase in

the mass flow of refrigerant, resulting

in an increase in capacity. The cooled

liquid refrigerant in the economizer

is metered through a float-type meter-

ing device into the cooler. Because

pressure in the cooler is lower than

the economizer pressure, some of the

liquid flashes and cools the remain-

der to evaporator (cooler) temperature.

During both the economized and

non-economized cycles, liquid refriger-

ant returns to the cooler to replenish

the refrigerant leaving as a result of

compressor suction. The cycle is now

complete.

7