Data Sheet

LT3652

10

3652fe

For more information www.linear.com/LT3652

APPLICATIONS INFORMATION

Overview

LT3652 is a complete monolithic, mid-power, multi-chem

-

istry buck battery charger, addressing high input voltage

applications with solutions that require a minimum of exter

-

nal components. The IC uses a 1MHz constant frequency,

average-current mode step-down architecture.

The LT3652 incorporates a 2A switch that is driven by

a bootstrapped supply to maximize efficiency during

charging cycles. Wide input range allows operation to full

charge from voltages as high as 32V. A precision threshold

shutdown pin allows incorporation of UVLO functionality

using a simple resistor divider. The IC can also be put into

a low-current shutdown mode, in which the input supply

bias is reduced to only 15µA.

The LT3652 employs an input voltage regulation loop,

which reduces charge current if a monitored input volt

-

age falls below a programmed level. When the LT3652 is

powered by a solar panel, the input regulation loop is used

to maintain the panel at peak output power.

The LT3652 automatically enters a battery precondition

mode if the sensed battery voltage is very low. In this mode,

the charge current is reduced to 15% of the programmed

maximum, as set by the inductor sense resistor, R

SENSE

.

Once the battery voltage reaches 70% of the fully charged

float voltage, the IC automatically increases maximum

charge current to the full programmed value.

The LT3652 can use a charge-current based C/10 termina

-

tion scheme, which ends a charge cycle when the battery

charge current falls to one tenth of the programmed

maximum charge current. The LT3652 also contains an

internal charge cycle control timer, for timer-based termina

-

tion. When using the internal timer, the IC combines C/10

detection with a programmable time constraint, during

which the charging cycle can continue beyond the C/10

level to top-off a battery. The charge cycle terminates

when a specific time elapses, typically 3 hours. When

the timer-based scheme is used, the IC also supports bad

battery detection, which triggers a system fault if a battery

stays in precondition mode for more than one eighth of

the total charge cycle time.

Once charging is terminated, the LT3652 automatically

enters a low-current standby mode where supply bias

currents are reduced to 85µA. The IC continues to monitor

the battery voltage while in standby, and if that voltage

falls 2.5% from the full-charge float voltage, the LT3652

engages an automatic charge cycle restart. The IC also

automatically restarts a new charge cycle after a bad bat

-

tery fault once the failed battery is removed and replaced

with another battery.

The LT3652 contains provisions for a battery temperature

monitoring circuit. This feature monitors battery tempera

-

ture using a thermistor during the charging cycle. If the

battery temperature moves outside a safe charging range

of 0°C to 40°C, the IC suspends charging and signals a

fault condition until the temperature returns to the safe

charging range.

The LT3652 contains two digital open-collector outputs,

which provide charger status and signal fault conditions.

These binary-coded pins signal battery charging, standby

or shutdown modes, battery temperature faults, and bad

battery faults.

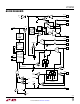

General Operation (See Block Diagram)

The LT3652 uses average current mode control loop

architecture, such that the IC servos directly to average

charge current. The LT3652 senses charger output voltage

through a resistor divider via the V

FB

pin. The difference

between the voltage on this pin and an internal 3.3V volt

-

age reference is integrated by the voltage error amplifier

(V-EA). This amplifier generates an error voltage on its

output (I

TH

), which corresponds to the average current

sensed across the inductor current sense resistor, R

SENSE

,

which is connected between the SENSE and BAT pins.

The I

TH

voltage is then divided down by a factor of 10,

and imposed on the input of the current error amplifier

(C-EA). The difference between this imposed voltage and

the current sense resistor voltage is integrated, with the

resulting voltage (V

C

) used as a threshold that is compared

against an internally generated ramp. The output of this

comparison controls the charger’s switch.