Product Manual

Operation

1. Locate the compressor as far away as

possible from the blasting area to

minimize the dust in the compressor

intake.

2. The air supply to blaster must be

clean and free of moisture and oil.

3. Use clean dry media in hopper.

4.

Use a compressor that can supply

enough air (See Specifications). A

compressor too small will cause air

pressure to drop and the blaster will

not operate satisfactorily.

5. Always trial test the blaster to make

sure the job is done without damage

by testing on a hidden surface.

6. When filling hopper, always filter

(screen) the abrasive material to

remove any caked material and

debris to prevent clogging.

7. Use the lowest effective pressure on

soft materials, aluminum, brass, glass,

and wood.

8. Use higher pressure for hard

materials.

9. Fill the hopper with abrasive to

about 3/4 full.

10. When set-up completed and wearing

proper safety equipment, aim blast

gun at surface and pull trigger.

11. Whenever the nozzle is removed and

cleaned or replaced, use a brush to

clean the threads and replace the o-

ring.

MODEL MXS11003

1. Attach the hose connector to the

hopper using the supplied conduit nut.

2. Attach the material hose to the hose

connector. Attach the opposite end

of the material hose to the gun (See

Figure 6).

NOTE: For spraying liquids, slip the

material hose fully on to the hose

connector covering the hole.

3. Attach the air compressor hose to the

air inlet (1/4"NPT(F)) at the bottom of

the gun handle. An optional quick

coupler and connector can be used to

attach the hose to the gun.

MODEL MXS11004

1. Attach the material hose to the hose

connector. Attach the opposite end

of the material hose to the gun (See

Figure 7).

NOTE: For spraying liquids, slip the

material hose fully on to the tank elbow

covering the hole.

2. Attach the air compressor hose to the

air inlet (1/4 in. NPT(F)) at the bottom

of the gun handle. An optional quick

coupler and connector can be used to

attach the hose to the gun.

Do not

work

around oily rags or flammable liquids.

Blasting media striking metal can cause a

spark and create a fire or explosion.

Do not spray acids or caustics.

Assembly

Model MXS11001

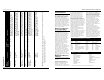

1. Attach material hose to the pick-up

tube. Place pick-up tube in bag of

medium. (See FIgure 4).

2. Attach the air compressor hose to the

air inlet (1/4 in. NPT(F)) at the bottom

of the gun handle. An optional quick

coupler and connector can be used to

attach the hose to the gun.

MODEL MXS11002

1. Attach the material hose to the hose

connector. Attach the opposite end

of the material hose to the gun (See

Figure 5).

2. Attach the air compressor hose to the

air inlet (1/4 in. NPT(F)) at the bottom

of the gun handle. An optional quick

coupler and connector can be used to

attach the hose to the gun.

2

Do not cover

this hole for

dry blasting

Conduit

nut

Attach air

hose

Hose connector

Material

hose

Attach

air

hose

Material

hose

Note: Do not cover hole in tank elbow

when dry blasting.

Figure 6 - Model MXS11003

Figure 7 - Model MXS11004

Do not cover this

hole when blasting

Attach air hose

Material

hose

Hose connector

Figure 5 - Model MXS11002

Attach air hose

Material hose

Pick-up tube

Figure 4 - Model MXS11001

Do not touch outer tube

with hose

Figure 3

Notes

Notes

Notas

19

www.maxustools.com

Operating Instructions MXS11001, MXS11002, MXS11003 y MXS11004

General Safety

Information (Cont.)