Product Manual

5

Abrasive Blasting

Media

Blasting media comes in many different

grit sizes and sometimes also rated as

extra fine, fine, medium, coarse, and

extra coarse. The larger the grit number,

the smaller the particle size; the smaller

the grit number, the larger the particle

size. Glass media can come in beads,

crushed, or ground. Aluminum oxide and

silicon carbide can come in several colors.

It is common today to find mixtures of

glass and aluminum oxide.

Acrylic

Aluminum oxide

Ceramic beads

Corn cob

Garnet

Glass Beads

Glass, crushed

Melamine

Pecan shell

Polyester

Pumice

Sand

Silicon carbide

Sodium Bicarbonate (soda)

Starch

Steel grit

Steel shot

Urea

Walnut shell

Available commercial abrasive blasting media

Abrasive Media - Not

Recommended

Although available, some media are not

recommended for use because of

mechanical and/or personal hazards.

Silica sand, a common blast media, has

health risk concerns due to the silica

content. Restriction on its usage is

common in many states.

Beach sand (play sand) is a common and

inexpensive blast media. This highly

aggressive media can have debris mixed

in which will cause clogging of

equipment.

Steel grit produces ideal surface

preparation on new coating. This media

should only be used in a special blast

cabinet designed for this media.

Steel shot, a round, solid particle, leaves

a dimples in a surface after blasting. It is

a very dense media and should only be

used in a special blast cabinet designed

for this media.

Common Abrasive

Media

The more commonly available media and

their uses are listed below.

Walnut shell is one of the most versatile

organic media due to its angular,

durable shape. It is still considered a soft

media, but it is good to use on delicate

parts. Use as an economical, bio-

degradable alternative for sensitive

blasting that will not scratch or damage

surfaces.

Glass beads are the most popular all-

purpose media used today. Used for

honing, polishing, peening, blending,

finishing, removing light burrs, frosting

glass, and cleaning most light materials.

Common uses in the removal of paint,

rust, and surface residues. Glass bead

blasting generally will not change the

dimensions of the item being blasted.

Glass beads produce brighter finish than

angular abrasives. Beads can be recycled

and used many times.

Crushed glass is very aggressive. Used for

economical, general clean-up.

Plastic is available in a variety of sizes

and materials (urea, acrylic, polyester,

and melamine). These materials are ideal

for application such as auto restoration

to deliver a high stripping rate without

damaging or warping the substrate

material.

Brown aluminum oxide is a widely used

abrasive media. This media produces a

textured surface, good for repairing

surfaces for recoating. It is excellent for

removing heavy foreign materials,

deburring, and etching glass and stone.

It is a fast-cutting media that can be

reused many times.

White aluminum oxide can be used in

the same applications as the brown

aluminum oxide, but white aluminum

oxide is considered to be a clean media,

used in high performance processes

where contamination of metal oxide

must be kept to a minimum.

Aluminum / glass mixtures provides a

combination of glass bead finishing and

aluminum oxide cleaning. It provides a

brighter finish than single abrasives, and

it is good for removing rust and machine

marks on metal.

Silicon carbide is the hardest Abrasive

material available. It is fast cutting and

can be reused many times. It is high in

initial cost, but removes material quickly

to reduce blasting time.

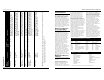

Common abrasive media guide

35-60 Walnut shell Good High Low

25-325 Glass beads Better Low Low

25-70 Crushed glass Better Low Low

30-40 Plastics Better Low High

24-400 Brown alum. oxide Best Low Med -High

150-240 White alum. oxide Best Low High

50-100 Alum./glass mixture Best Low Med

24-240 Silicon carbide Best Low High

Grit Abrasive Abrasive Dust Relative

Range Type Life Level Cost

Consult your abrasive supplier for recommendations.

16 Sp

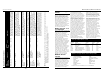

NOTA: El abrasivo que no ha sido limpiado y tamizado puede contener material que obturará la boquilla de la pistola y no debería usarse.

Use baja presión de aire (4,14 bar o menos) para los metales blandos, vidrio y madera.

Use una presión más elevada para aceros duros; no exceda los 8,62 bar.

Perlas de vidrio

Cáscara de

nuez molida

Perlas de

vidrio, cáscara

de nuez molida

Óxido de

aluminio

Cáscara de

pecano o nuez

molida y

mazorca molida

Óxido de

aluminio (50-80)

Para

grabar

vidrio

Preparación o

meteorización

de madera

Lijado de

madera

y acabado de

muebles

Limpieza de

repuestos de

automóviles

Limpieza o

preparación

para la pintura

Limpieza o

raspado de

equipo

expuesto al

intemperie

2,54 cm -

10,16 cm

5,08 cm -

15,24 cm

2,54 cm -

15,24 cm

2,54 cm -

10,16 cm

2,54 cm -

15,24 cm

2,54 cm -

7,62 cm

2,76 - 6,21

2,76 - 6,21

2,76 - 4,83

2,76 - 5,52

2,76 - 8,62

3,45 - 8,62

Mueva la pistola adelante y atrás siguiendo un patrón como

si estuviera usando una brocha. Rocíe en un ángulo de 900.

Para un brillado fino, use perlas de vidrio como abrasivo.

Aplique movimientos como de brocha y observe

cuidadosamente la intensidad de la abrasión. La madera

blanda se desgasta más rápidamente que la madera dura.

El abrasivo de grano pequeño produce un acabado más

fino. Empiece con presión baja y auméntela

gradualmente. Rocíe en un ángulo de 45

o

.

Aplique movimientos como de brocha y observe

cuidadosamente la intensidad de la abrasión. Use cáscara

de nuez para un acabado rústico y perlas de vidrio para el

acabado final. Rocíe en un ángulo de 45

o

.

Use material abrasivo de grano mayor para las área no a la

vista. Si el material de base queda dañado, use un abrasivo

de grano menor. Rocíe en un ángulo entre 80 y 90

o

.

Aplique movimientos como de brocha y observe

cuidadosamente la intensidad de la abrasión. La madera

blanda se desgasta más rápidamente que la madera dura.

El abrasivo de grano pequeño produce un acabado más

fino. Empiece con presión baja y auméntela

gradualmente. Rocíe en un ángulo entre 45 y 60

o

.

Retire la pintura descascarada con un cepillo de alambre,

luego rocíe con un abrasivo de grano grueso. Es necesario

raspar primero las capas múltiples de pintura vieja.

Después de rociar con abrasivo, aplique de inmediato un

imprimador para evitar la corrosión. Rocíe en un ángulo

entre 45 y 60

o

.

Tipos de Distancia

Abrasivo Aplicación de la pieza bar Sugerencias

(Cernido/Tamaño) de trabajo

Usos Sugeridos

www.maxustools.com

MXS11001, MXS11002, MXS11003 and MXS11004Manuel de Instrucciones