Owner's manual

13

PROBLEM POSSIBLE CAUSE SOLUTION

1

Driving

blade does

not retract

1. Zero of Low air pressure Check air supply for 80 psi minimum to 110 psi maximum

2. Lack of lubrication Manually lubricate through male air inlet fi tting

3. Excessive dirt inside Stapler Disassemble and clean

4. Bent or burred driving blade Replace driving blade (15)

5. Seals worn out Replace all seals (Seal Kit A-5)

6. U-Cup Lip Seals installed upside down Replace all seals (Seal Kit A-5)

7. Seals need to be seated — dry fi re Stapler

2

Driving

blade

retracts

slowly

1. Low air pressure Turn up air pressure to 80-110 psi max

2. Lack of lubrication Manually lubricate through male air inlet fi tting

3. Air supply restricted by small orifi ce Use 1/4" minimum diameter air fi ttings

4. U-Cup Lip Seals installed upside down Replace all seals (Seal Kit A-5)

5. Excessive dirt inside nailer Disassemble, clean and lubricate

3

Staple is not

countersunk

1. Low air pressure Turn up air pressure to 80-110 psi max

2. Broken Driving Blade Replace Driving Blade (15)

3. Stapler hit hard surface Move from obstruction

4. Driving blade jam nut came loose Retighten or replace jam nut (22)

5. Worn out gate Replace gate (28)

4

Stapler

leaks air

1. Air supply fi ttings loose Tighten all air line fi tting connections

2. Dry wall dust in Stapler Rebuild Stapler

3. Excess air pressure blew out seals Check air supply for 110 psi maximum—replace all seals

4. Plunger screws loose Tighten 3 plunger screws (8)

5. Cracked or damaged body Replace body (1)

6. Seals worn out Replace all seals (Seal Kit A-5)

7. Seals need to be seated Dry fi re Stapler

5

Bottom

of stapler

cracked off

1. Operated without rubber bumper installed Replace damaged parts

2. Excessive air pressure used Replace damaged parts

6

Staples jam

in nailer

1. Not using Powerstapler™ Staples Use Powerstapler™ Staples only (2”,1-3/4”,1-1/2” Lengths)

2. Continued use after a short hit Clear staple immediately after short hit

3. Staple pusher damaged or spring broken Replace staple pusher assembly (A-10)

4. Staple channel loose Tighten staple channel retaining screws (34, 41)

5. Bent staple stuck in staple guide Disassemble and clear out bent staple

6. Hit another set staple or hard object Move from obstruction

7. Stapler gate worn out Replace staple gate (28)

7

Plunger

locked

up—won't

move or fi re

1. Lack of lubrication Manually lubricate through male air inlet fi tting

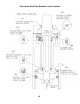

PowerStapler 445FS Trouble Shooting Chart