Datasheet

CONFIDENTIAL DOCUMENT

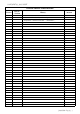

7. Performance specification :

*Insulation

1,000 MΩ or more

Apply 500V DC between protective coating

resistance and termination for 1 min, then measure

(Sub-clause 4.6)

*Dielectric No evidence of flashover Apply 100V(0402) 300V(0603) & 500V (0805,1206,1210,2010,

withstanding mechanical damage, arcing or 2512) AC between protective coating

voltage insulation break down and termination for 1 minute (Sub-clause 4.7)

Natural resistance change per temp.

degree centigrade.

1-10 : ± 400 PPM/℃ R

2-R1

Temperature 11-100 : ± 200 PPM/℃

x 10

6

(PPM/℃)

coefficient >100 : ± 100 PPM/℃ R

1(t2-t1)

R

1: Resistance value at room temperature (t1)

R

2: Resistance value at room temp. plus 100 ℃ (t2)

(Sub-clause 4.8)

Short time Resistance change rate is Permanent resistance change after the

overload

± 5% (2.0% + 0.1Ω) Max.

application of a potential of 2.5 times RCWV

± 1% (1.0% + 0.1Ω) Max.

for 5 seconds

(Sub-clause 4.13)

Test temperature of solder : 245

℃

*Solderability 95 % coverage Min. Dipping them solder : 2-3 seconds

(Sub-clause 4.17)

Wave soldering condition:

(2 cycles Max.)

Soldering temp. Electrical characteristics shall be

Pre-heat : 100 ~ 120 ℃, 30 ± 5 sec.

reference satisfied. Without distinct

Suggestion solder temp.: 235 ~ 255 ℃, 10 sec. (Max.)

deformation in appearance. Peak temp.: 260 ℃

(95 % coverage Min.) Reflow soldering condition:

(2 cycles Max.)

Pre-heat : 150 ~ 180 ℃, 90 ~ 120 sec.

Suggestion solder temp.: 235 ~ 255 ℃, 20 ~ 40 sec.

Peak temp.: 260 ℃

Hand soldering condition:

The soldering iron tip temperature should be less than

300℃and maximum contract time should be 5 sec.

Thick Film Chip Resistors (Terminal Lead Free)

LimitsCharacteristics

Test Methods

( JIS C 5201-1 )

Page 5.

2014/05/08--Version: 1