Instructions / Assembly

3

TM

WARNING

SPREADER CANNOT BE SUPPORTED BY FRAME ONLY!

SPREADER HOPPER MUST REST ON BUMPER OR SIMILAR

STRUCTURE ATTACHED TO TRUCK FRAME.

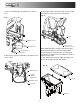

Fig. 3

Fig. 6

3. Align holes in rear portion of the hopper with slots

in frame uprights. Use slots which will position spreader

with a slight upward tilt. Secure hopper assembly to frame

using ½-13 x 3.0 screws, flat washers and nuts. Fig.3. Do

not tighten fasteners at this time.

4. Slide hopper and frame towards tailgate leaving about

3/8” to ½” space. Align closest holes in hitch receiver with

holes in frame. Secure frame in hitch receiver using 5/8

hitch pin and cotter pin. Fig.4.

5. Assembly ½-13 x 6.0 screws with flat washers and ½-13

flanged nuts and nylock nuts as shown in Fig.5. Make sure

that nuts located between hopper side brackets and frame

positioned exactly as shown. These nuts must not be in

contact with brackets and frame at this time.

6. Tighten nuts located under frame evenly on both sides

of the spreader (10-15 ft-lb’s. torque). Then

tighten bolts in frame uprights. Finally tighten nuts located

between hopper side brackets and frame.

They must look as shown in Fig.6. After this procedure

spreader should be securely attached to trucks bumper

and frame.

1/2-13 X 3.0 SCREW

1/2 FLAT WASHER

1/2-13 NYLOCK NUT

SCREW 1/2-13 X 6.0

NUT 1/2-13 FLANGED

WASHER 1/2 FLAT

NYLOCK NUT 1/2-13

HITCH PIN

COTTER PIN

Fig. 4

Fig. 5