Product Manual

Table Of Contents

- Installation

- Loading and operation

- Battery-powered units' info

- Maintenance and safety checks

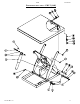

- Structural exploded views

- Structural bills of materials

- Motor and transformer connections

- Electrical diagrams

- Hydraulic diagrams

- Power unit operation, valve issues

- Modular power unit parts

- Troubleshooting

- Safety label identification

- Warranty

02/06 24-126-120

V

ESTIL MFG. CO. 5

ROUTINE MAINTENANCE & SAFETY CHECKS – EHLT (1-4K) & PST (1-3K)

o Warning: Care should be taken to identify all potential hazards and comply with applicable safety procedures

before beginning work.

o Warning: Install the maintenance props before beginning any inspections or work on the unit. See below.

o Only qualified individuals trained to understand mechanical devices and their related electrical and hydraulic

circuits, and the hazards associated with them, should attempt troubleshooting and repair of this equipment.

Maintenance Prop Installation:

Always install the maintenance prop or fully lower the platform before beginning work on the scissor lift table.

A maintenance prop is located on the outside of each of the outer legs of the legset.

To install the safety maintenance props:

• Raise the platform to its full raised height.

• Rotate each prop forward so that it’s free end drops down onto the lift table’s frame.

• Lower the platform until the maintenance props rest against the end member of the frame.

(A) Inspect daily for:

1.) Frayed wires.

2.) Oil leaks.

3.) Pinched or chafed hoses.

4.) Damage to the casters. (Portable units.)

5.) Damage or structural deformation to the structural members, the cylinder brackets, etc.

6.) Unusual noise or binding, or evidence thereof.

7.) Proper functioning of all limit switches, including those on the perimeter pinch point guard (if applicable).

(B) Inspect monthly for:

1.) The oil level. Oil should be 1” to 1½” below the reservoir’s fill hole with the platform in the fully lowered

position. See below for the hydraulic oil specification.

2.) Worn or damaged hydraulic hoses and electrical wires.

3.) Pivot point wear.

4.) Rollers’ looseness and wear.

5.) Integrity of the retaining hardware on all rollers and on all pivot point pins.

6.) The integrity of the frame anchor bolts, and for cracks in the concrete around them. (Non-portable units.)

7.) Looseness, wear, or damage to the casters’ bearings, mounting hardware, or surface material. (Portable units.)

8.) Proper functioning of any hand- or foot-operated mechanisms.

9.) Proper water level in the battery (DC units.)

10.) Unusual noises or movement during operation.

11.) All the information/safety/warning labels being in place and in good condition.

12.) The need to clean off dirt and debris.

(C) Yearly inspection

The oil should be changed if the oil darkens, becomes gritty, or turns a milky color (indicating the presence of

water). Replace with an anti-wear hydraulic oil with a viscosity grade of 150 SUS at 100°F, (ISO 32 at 40°C). Ex:

AW 32 or HO 150 hydraulic oil, or a non-synthetic transmission fluid. You may use a synthetic transmission fluid if

you flush the system with the synthetic fluid before filling the reservoir.