Hardware manual

Installation and parameter setup for communication profiles

38

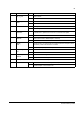

PROFIdrive communication profile (Speed Control Mode) PPO Type 4

The start/stop commands and reference are according to the PROFIdrive profile

Speed Control Mode. This example employs PPO Type 4 cyclical message. Set

parameters as given in the Application-specific setting column in the table below.

A reference value of ±16384 (4000h) corresponds to parameter 19.01 SPEED

SCALING in forward and reverse directions.

Process data mapping is as follows:

Drive control parameters

Use DriveStudio PC tool for drive parameter setup. The Application-specific setting

column gives the value to use when the fieldbus interface is the desired source or

destination for that particular signal. The Function/Information column gives a

description of the parameter.

Direction PZD1 PZD2

Out Control Word Speed reference

In Status Word Speed actual value

Parameter Application-

specific setting

Function/Information

CONTROL COMMAND SOURCE SELECTION

10.01 EXT1 START

FUNC

(3) FBA EXT1 start and stop commands are taken from the fieldbus.

12.03 EXT1 CTRL MODE (1) Speed Speed control. Torque reference is 03.09 TORQ REF SP CTRL.

19.01 SPEED SCALING 1500 Defines the terminal speed value used in acceleration and the initial

speed value used in deceleration. Speed reference scaling is defined

by the used fieldbus profile (e.g. with PROFIdrive profile integer value

16384 (4000h) corresponds to parameter 19.01 SPEED SCALING

value). Signal 01.01 Motor speed rpm is sent to the fieldbus as an

actual value.

21.01 SPEED REF1 SEL FBA ref1 Selects the source for speed reference 1.

SYSTEM CONTROL INPUTS

16.07 PARAM SAVE (0) DONE

(1) SAVE

Saves parameter value changes (including those made through

fieldbus control) to permanent memory.