Operating instructions

Table Of Contents

- OPERATING INSTRUCTIONS

- Table of Contents

- 1 General Information

- 2 Safety

- 3 Scope of Delivery

- 4 Equipment Specifications

- 5 Functional Description

- 6 Storage and Transport

- 7 Installation

- 8 Commissioning

- 9 Operation

- 10 Maintenance

- 11 Decommissioning and Dismantling

- List of Tables

- List of Figures

Protect PV.600/800 OD Series - Operating Instructions

Page 52 of 100 8000041160 BAL

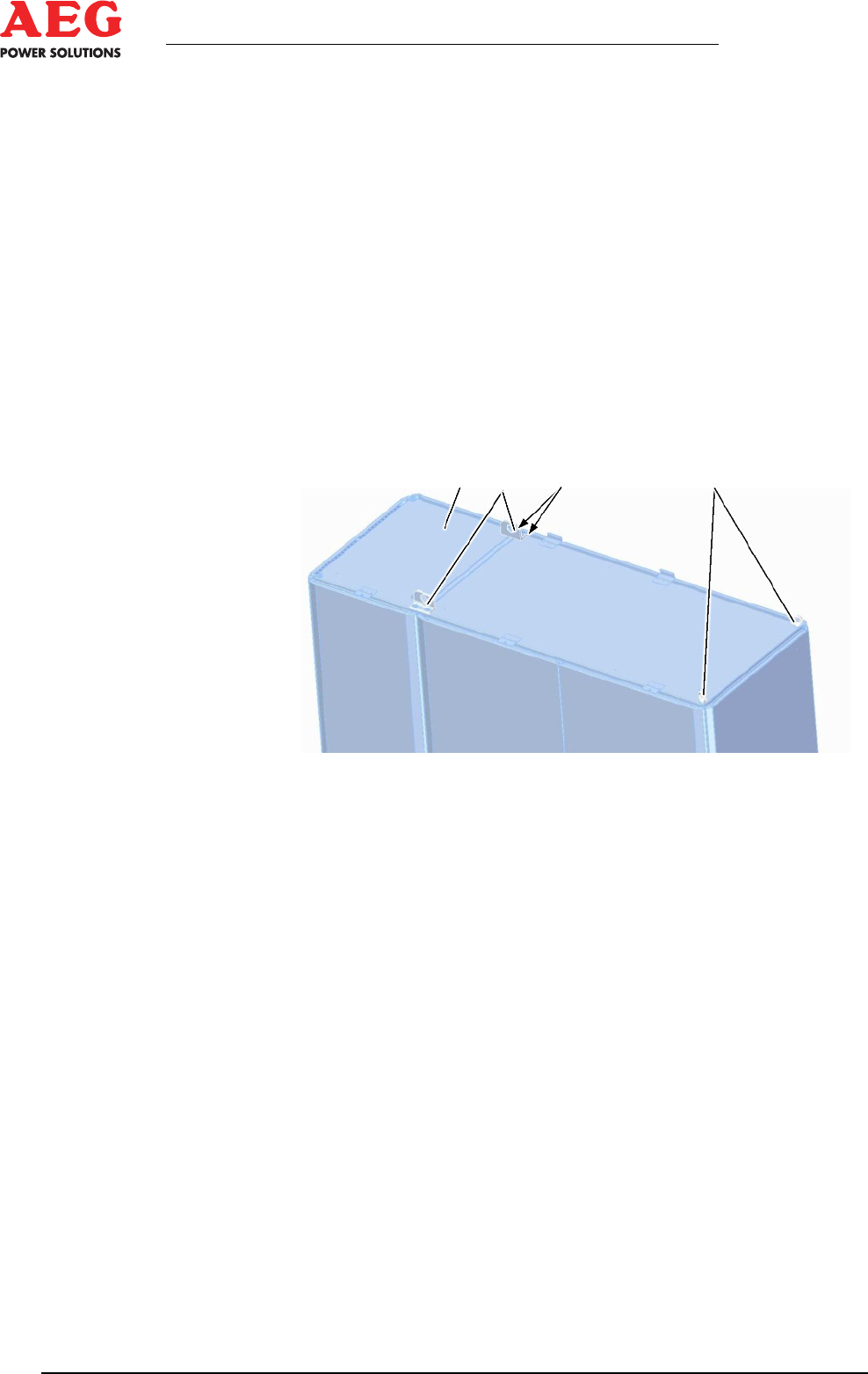

• Screw the eye bolts fully into the threaded holes. The bottom

flange must lie completely flat and flush with the surface of the

cabinet.

• Fasten the supporting bracket with screw connections in the

threaded holes of the INV and AC cabinet.

• Calculate the length of the ropes (chains, ropes or straps) in

such a way that an angle of >45° (F2) is formed between the

sling gear and the top of the cabinet. The ropes (DIN EN 1492)

must always be of the same length to ensure uniform load dis-

tribution and avoid tilting of the equipment.

• The load-bearing capacity of each item of sling gear must have

a capacity of at least half of the cabinet weight as a precaution.

• Use one rope per transport eyelet, i.e. four per cabinet and a

total of eight per unit.

1 2 3 4

Figure 12 - Lifting points

1 Top of the cabinet without roof

2 Supporting bracket

2 Threaded hole

4 Eye bolt

Implementation

1. Check the lifting points and the sling gear for damage and re-

place immediately if you identify any tears or deformation.

2. Attach the ropes to the transport eyelets.

3. Check that the transport eyelets and ropes are fastened cor-

rectly.

4. Unscrew and remove the screw connections from the transport

pallet. If necessary, remove the ventilation grids first.

5. Carefully lift the equipment and transport it to its intended in-

stallation location.

6. Lower the equipment carefully, feed the cables into it from be-

low terminal diagram (*.TD), position it at the installation lo-

cation and set it down without any jolts.

7. Check the stability of the equipment and secure it at the instal-

lation location.

8. Remove the sling gear and the lifting points.

9. Put the roof on and secure it.