Operating instructions

Table Of Contents

- OPERATING INSTRUCTIONS

- Table of Contents

- 1 General Information

- 2 Safety

- 3 Scope of Delivery

- 4 Equipment Specifications

- 5 Functional Description

- 6 Storage and Transport

- 7 Installation

- 8 Commissioning

- 9 Operation

- 10 Maintenance

- 11 Decommissioning and Dismantling

- List of Tables

- List of Figures

Protect PV.600/800 OD Series - Operating Instructions

8000041160 BAL Page 93 of 100

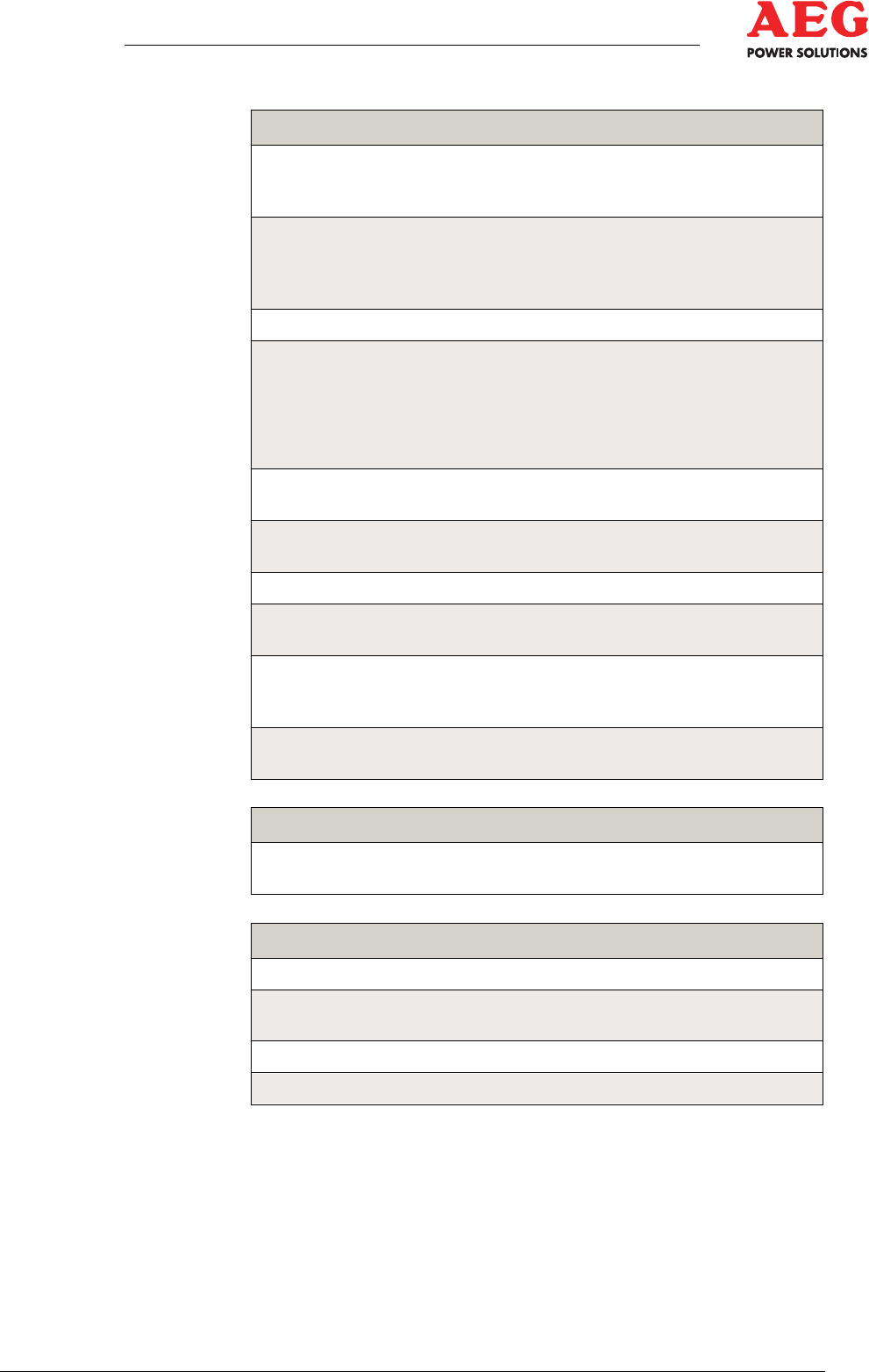

Annually

Measuring and monitoring devices must comply with the VDE 0413

standard.

Check and calibrate all measuring instruments.

Check all input, monitoring and output values in the equipment and

also in interaction with the external control system. Check the control

b

ehaviour of the equipment and readjust, correct or change the limit

values if required.

Check the inverter control and inverter function.

Check that the equipment as a whole is in perfect working order:

- Check housing for damage

- Check line connections for dirt and corrosion

- Check protective covers for damage and check their

fastenings

Check the function of the peripheral connections, i.e. all connections of

the various accessory systems, and repair them if required.

Clean the equipment to minimise creepage currents (do not use water).

Comply with BGV A3, DIN VDE 0105-100 during this process.

Clean ventilation grilles and holder.

Check radial ventilators/fans for damage and whether they are working

correctly (rotation), and repair or replace if necessary.

Check that the safety signs are complete and legible, and replace if

required.

(Must be checked by an expert every 2 years.)

Check function of lighting in control cabinet and operating area, and

replace if necessary.

Every 2 years

Check of the safety signs in the operating area and in the equipment

by an expert.

Every 10 years

Replace 3 V lithium battery on PCB A17 (INV).

Replace radial ventilators/fans in equipment ventilation system and

clean ventilation duct and cooling fins.

Replace starting capacitors.

Replace output contactor K7 coils.