Specification Sheet

3

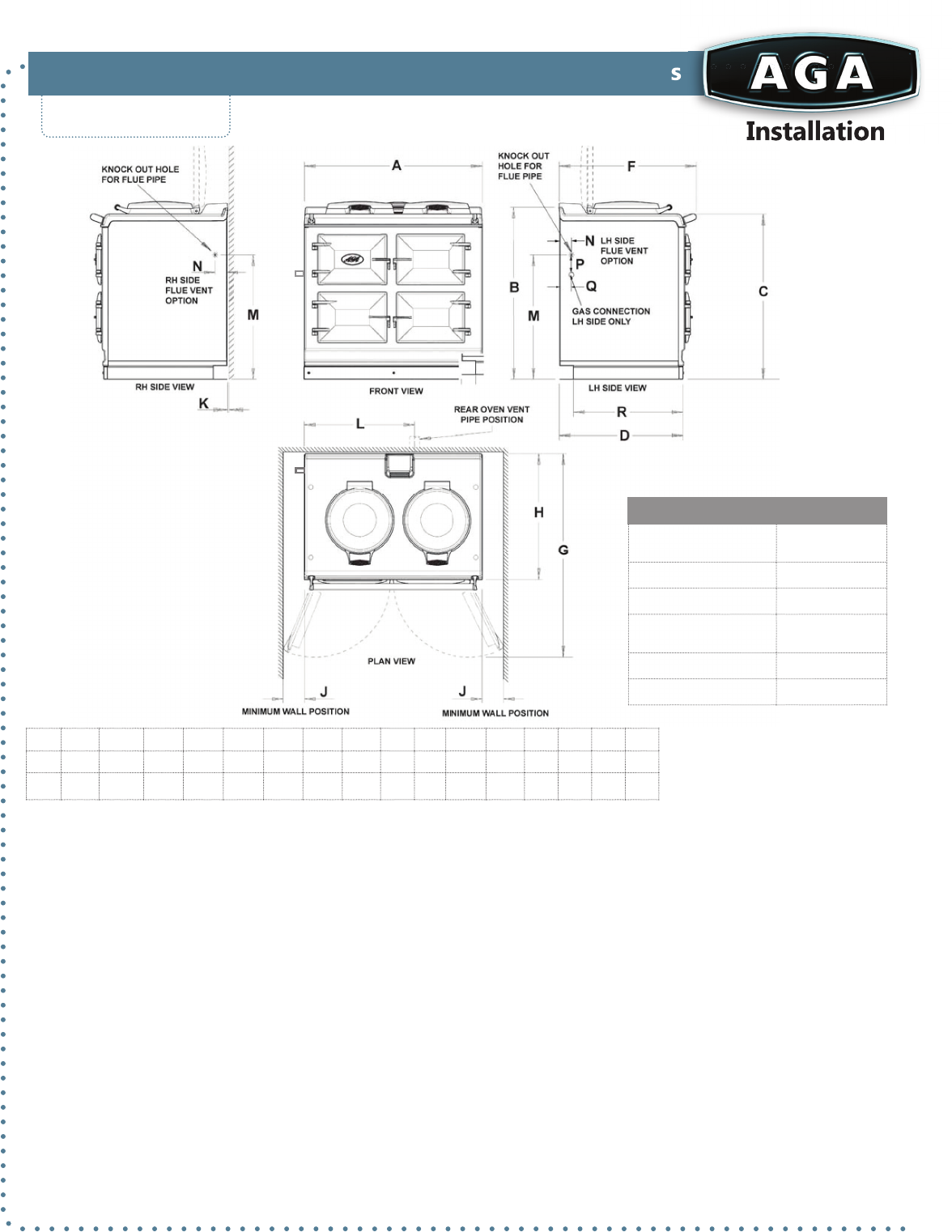

AGA Dual Control 3-Oven Cast Iron Range – Natural Gas

Model # ADC3G

Installation

AGA Dual Control 3-Oven Cast Iron Range – Natural Gas

Installation

Installation

Range Dimensions

When surveying for a range installation the actual clearance required

for the ‘body’ of the appliance should be increased by ⅜" (10mm)

beyond the fi gures quoted above. This allows safe margin to take into

account the natural dimensional variations found in major castings. In

particular the width across the appliance recess could be critical.

Range Base or Hearth

It is essential that the base or hearth on which the range stands should

be level. The base of the built-in AGA plinth must be level and sit above

fi nished fl oor height for service access.

Plinth

The front plinth cover is removable and must not be obstructed by

fl ooring or tiles. If necessary the range must be raised by the thickness of

the tiles to ensure the plinth can be removed.

Minimum Clearance to Combustibles

A gap of at least ½" must be observed between the rear of the top plate,

and the wall behind the appliance. If the rear wall is of combustible

material there must be a gap of 1" (25mm).

Side Clearances

A ⅛" (3mm) gap is required each side between the range top

plate and adjoining work surfaces that may be fi tted, this is

to allow for the safe removal of the top plate should this be

required at a later date.

Where ranges are fi tted against side walls a 4 9/16" (116mm)

side clearance is required on the right and left hand side for

oven doors access.

If the AGA is to be installed in a brick recess, then the minimum

clearance should be increased by at least ⅜" (10mm), to allow

for the walls not being square.

In addition a minimum clearance of 39½" (1000mm) must be

available at the front of the range to enable it to be serviced.

Range Hoods

It is recommended this AGA is fi tted with a range hood. The

AGA venting system is located on top of the AGA between the

two hotplates, and is designed for venting the moisture from

the ovens. The range hood should be positioned not less than

the minimum height as recommended by the manufacturer,

from the top of the AGA.

NATURAL GAS

MAXIMUM HEAT

INPUT

6,800 Btu/hr

Thermostat Bypass

70

Main Burner Injector

112

Gas Supervision Injec-

tor

4212

Inlet Pressure

8” w.g.

Burner Pressure

4” w.g.

A B C D E F G H J K L M N p Q R

mm 987 948 910 680 1388 756 1145 698 116 10 565 689 43 118 55 634

ins 38⅞ 37�/8 35⅞ 26¾ 54⅝ 29¾ 45⅛ 27½ 4⅝ �/8 22¼ 27⅛ 1¾ 4⅝ 2⅛ 25

Specifi cations are subject to change without notice. Visit www.aga-ranges.com for the most up-to-date information.