SDS

Allura™ Lap & Vertical Siding, Soffit, Shakes and Trim & Fascia Board, Fiber Cement Underlayment & BackerBoard

Page 6

Preparation Date: 15 Sep 2017

Format: GHS Language: English (US)

WHMIS, OSHA HCS 2012

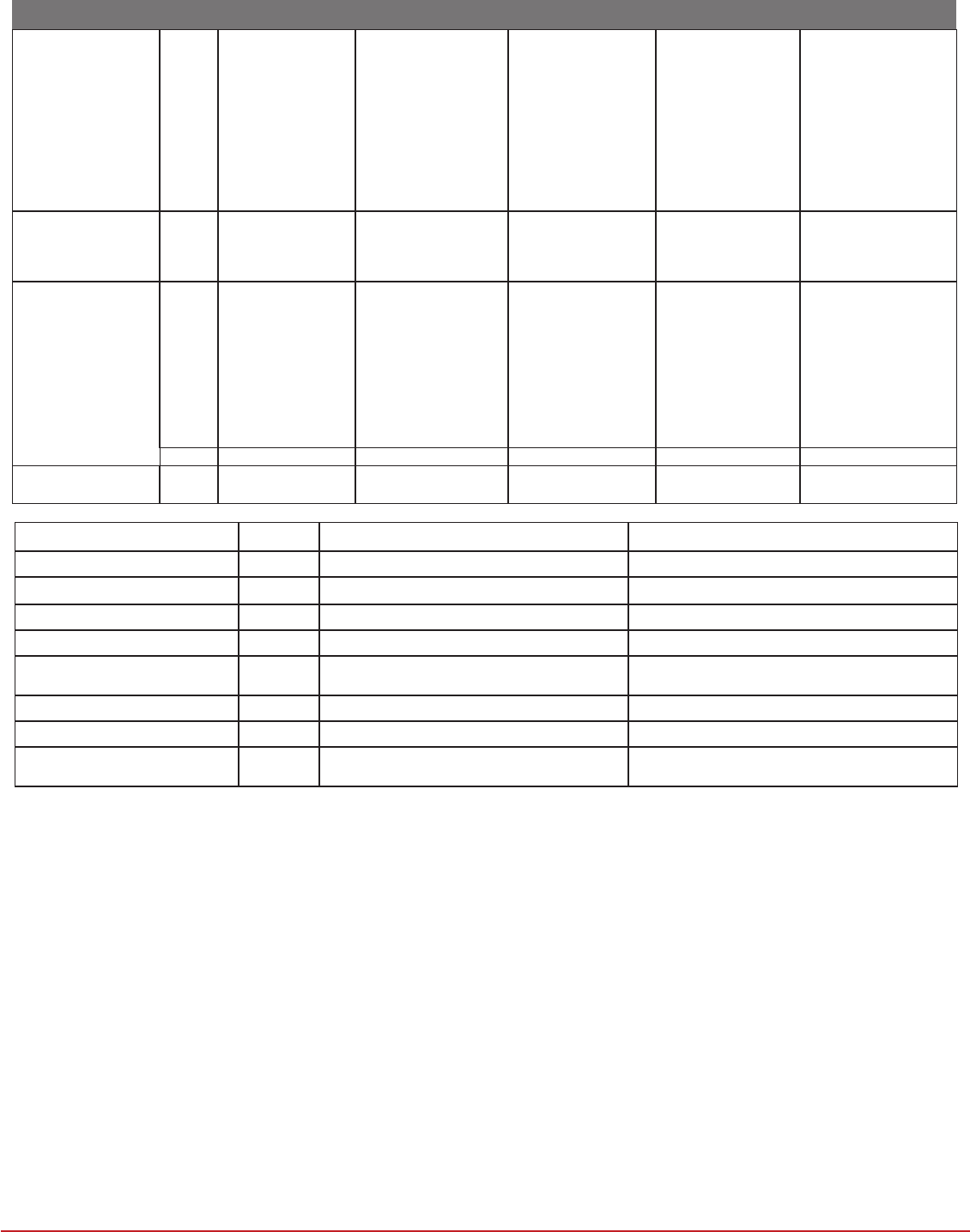

EXPOSURE LIMITS/GUIDELINES CONT’D

Silica, amorphous

TWAs Not established

2 mg/m3 TWA

Not established Not established

300 particle/mL TWA

(7631-86-9)

(respirable mass); 5

(as measured by

mg/m3 TWA (total

Konimeter

mass); 0.05 mg/m3

instrumentation, listed

TWA (regulated

under Silica); 20

under Silica flour,

mppcf TWA (as

respirable mass);

measured by Impinger

0.15 mg/m3 TWA

instrumentation, listed

(regulated under

under Silica); 2 mg/m3

Silica flour, total mass)

TWA (respirable mass,

listed under Silica)

Quartz

TWAs

0.025 mg/m3 TWA

0.1 mg/m3 TWA

0.10 mg/m3 TWA

0.1 mg/m3 TWAEV

300 particle/mL TWA

(14808-60-7)

(respirable fraction)

(respirable mass);

(designated

(respirable dust)

(listed under Silica)

0.3 mg/m3 TWA (total

substance regulation,

mass)

respirable)

Portland Cement

TWAs

1 mg/m3 TWA

5 mg/m3 TWA

10 mg/m3 TWA

10 mg/m3 TWAEV

30 mppcf TWA; 10

(65997-15-1)

(particulate matter

(respirable mass); 10

(containing no

(containing no

mg/m3 TWA

containing no

mg/m3 TWA (total

Asbestos and <1%

Asbestos and <1%

Asbestos and <1%

mass)

Crystalline silica, total

Crystalline silica,

Crystalline silica,

dust)

total dust); 5 mg/m3

respirable fraction)

TWAEV (containing

no Asbestos and

<1% Crystalline

silica, respirable

dust)

STELs

Not established

Not established

Not established

Not established

20 mg/m3 STEL

Aluminum hydroxide

TWAs

Not established Not established

1 mg/m3 TWA

Not established Not established

(21645-51-2)

(respirable fraction)

Result

NIOSH

OSHA

Magnesium oxide (1309-48-4) TWAs

Not established 15 mg/m3 TWA (fume, total particulate)

Calcium oxide (1305-78-8) TWAs

2 mg/m3 TWA 5 mg/m3 TWA

Titanium dioxide (13463-67-7) TWAs

Not established 15 mg/m3 TWA (total dust)

Iron oxide (1309-37-1) TWAs

5 mg/m3 TWA (dust and fume, as Fe) 10 mg/m3 TWA (fume)

Aluminum oxide (1344-28-1) TWAs

Not established

15 mg/m3 TWA (total dust); 5 mg/m3 TWA

(respirable fraction)

Silica, amorphous (7631-86-9) TWAs

6 mg/m3 TWA Not established

Quartz (14808-60-7) TWAs

0.05 mg/m3 TWA (respirable dust) 0.05 mg/m3 TWA (respirable dust)

Portland Cement (65997-15-1) TWAs

10 mg/m3 TWA (total dust); 5 mg/m3 TWA

15 mg/m3 TWA (total dust); 5 mg/m3 TWA

(respirable dust)

(respirable fraction)

Exposure Controls - Engineering Measures/Controls

•

Keep exposures to dust generated from cutting, drilling, routing, sawing or crushing, as low as possible.

•

Perform cutting of boards in a well-ventilated area (outside) and use local exhaust ventilation to keep exposures

below the recommended exposure limits.

•

When using power saws, use blades designed for fiber cement siding.

•

Use circular saws with a built-in dust collection container or shroud that functions as a hood, partially encloses the

saw blade, that is connected to the local area ventilation system (such as shop vacuum).

•

Use a shop vacuum having a filter with 99% or greater efficiency (HEPA recommended), with an air-flow rate as

specified by the saw manufacturer.

•

Use of high efficiency disposable filter bags is recommended as a pre-filter in the shop vacuum to capture most of the

dust. This will prolong the life of the cartridge filter and contain the dust to reduce exposure during disposal.

Personal Protective Equipment

Respiratory • If exposure controls listed above are not implemented, use NIOSH N-95 respirators when cutting, drilling,

sanding,etc.

Eyes/Face/Hands • Safety glasses with side shields should be worn at a minimum.

Skin/Body • Normal work clothing (long sleeved shirts and long pants) is recommended.