Installation Instructions

9

M965645 EN REV. 2.2 (10/19)

A

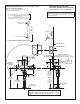

ADJUST STOP VALVE; Fig. 12

IMPORTANT: To avoid overowing, the STOP

VALVE (3) must never be opened to the point

where the ow from the valve exceeds the

draining ability of the xture.

1. After installation is complete, peel off the PROTECTIVE

FILM (1) from the sensor. Standing to one side, block the

sensor with your hand for 10 seconds.

Remove your hand and listen for audible “click” from

within the valve.

2. Remove STOP VALVE COVER (2) from STOP VALVE (3).

Turn on water supply 1/4 turn to 1/2 turn (CCW) and test

for leaks.

Note: Unit may ush for approximately 5 to 10 sec. when

water is rst turned on. If ow persists, turn water off and

repeat step #1 above.

3. Actuate the FLUSH VALVE:

A) Cover sensor with hand for 10 seconds.

NOTE: Stand outside of sensor detection area.

B) Remove hand from sensor detection area; unit will

ush in approximately 3 seconds.

4. Adjust STOP VALVE (3) after each ush until the stated

ush volume is achieved, no splashing occurs and the

xture is properly cleansed.

5. When adjustment is complete, replace STOP VALVE

COVER (2) and tighten to ensure vandal-resistance.

1

Fig. 12

2

CLOCKWISE CLOSES

STOP VALVE

3

COUNTER-CLOCKWISE

OPENS STOP VALVE

REMOVE COVER

MAINTENANCE

9

COVER PLATE FRAME AND

COVER PLATE INSTALLATION

(front installation); Fig. 11

1. After power supply is remotely installed and wire

connections are completed, install the COVER PLATE

FRAME (1) onto the ELECTRICAL BOX (2).

2. Install the two tabs on the back side of the COVER PLATE

(3) into the two Slots located on the top edge of the

COVER PLATE FRAME (1). Push on bottom until it snaps

into place.

CAUTION: Use only American Standard supplied transformers

and cable sets. Using non-AS supplied cables, or cutting,

splicing or modifying any components will void the warranty.

Fig.10a

TABS

SLOT

SLOT

1

3

2

Fig. 9

BLACK & WHITE

POWER

CONNECTIONS

10' EXTENSION

1

2

7

Fig. 11