Installation Instructions

6. MAINTENANCE

6.1. GENERAL REMARKS

It is recommended that the following inspections be carried out on

the boiler at least once a year:

1. Check the seals in the water group and, if necessary, replace

the gaskets and restore the seal to perfect working order.

2. Check the seals in the gas group and, if necessary, replace the

gaskets and restore the seal to perfect working order.

3. Visually check the overall state of the boiler.

4. Visually check the combustion and, if necessary, disassemble

and clean the burner.

5. Following inspection 3, disassemble and clean the combustion

chamber, if necessary.

6. Following inspection 4, disassemble and clean the injector, if

necessary.

7. Clean the primary heat exchanger (see section 6.2)

8. Regulate the correct rate of flow of the gas: rate of flow on

ignition, partially loaded and at maximum load.

9. Check the correct functioning of the heating safety devices:

- temperature limit safety device.

10. Check the correct functioning of the gas group safety devices:

- absence of gas or flame safety device (Ionisation).

11. Check that the electrical connections are correct (in conformity

with the instructions manual).

12. Check the efficiency of the production of domestic hot water

(test the rate of flow and temperature).

13. Carry out a general inspection of the functioning of the boiler.

14. Check the characteristics for expulsion of the products of

combustion.

15. Remove the oxide from the detection electrode by means of an

emery cloth.

CLEANING THE EXHAUST SIDE

Remove the combustion chamber inspection hatch (20) (see section

1.3). Check that the exhaust passages between the blades of the

block are free; if there are deposits present, wash the blades with

compressed air, water or a vinegar-based detergent.

NOTE: it is possible to use a brush in order to mechanically remove

the residues.

Use of detergents:

- soak the blades well

- allow the detergent to act for about 20 minutes

- rinse with a strong jet of water to remove the deposits (the

control panel must be kept closed)

- make sure that there are no traces of detergents in the

exchanger.

CLEANING THE WATER SIDE

Use detergents that dissolve CaCO3. Leave to act for a short time

(in order not to damage the aluminum) and then rinse. Make sure

that the detergent does not remain inside the exchanger.

Unscrew the lower part of the condensate trap and clean it. Lastly, fill

it with water and replace the stopper.

NB: if the boiler is not to be used for a prolonged period, the

condensate trap should be filled before igniting it again. A shortage

of water in the trap is dangerous because there is the risk of exhaust

fumes escaping into the air.

22

275

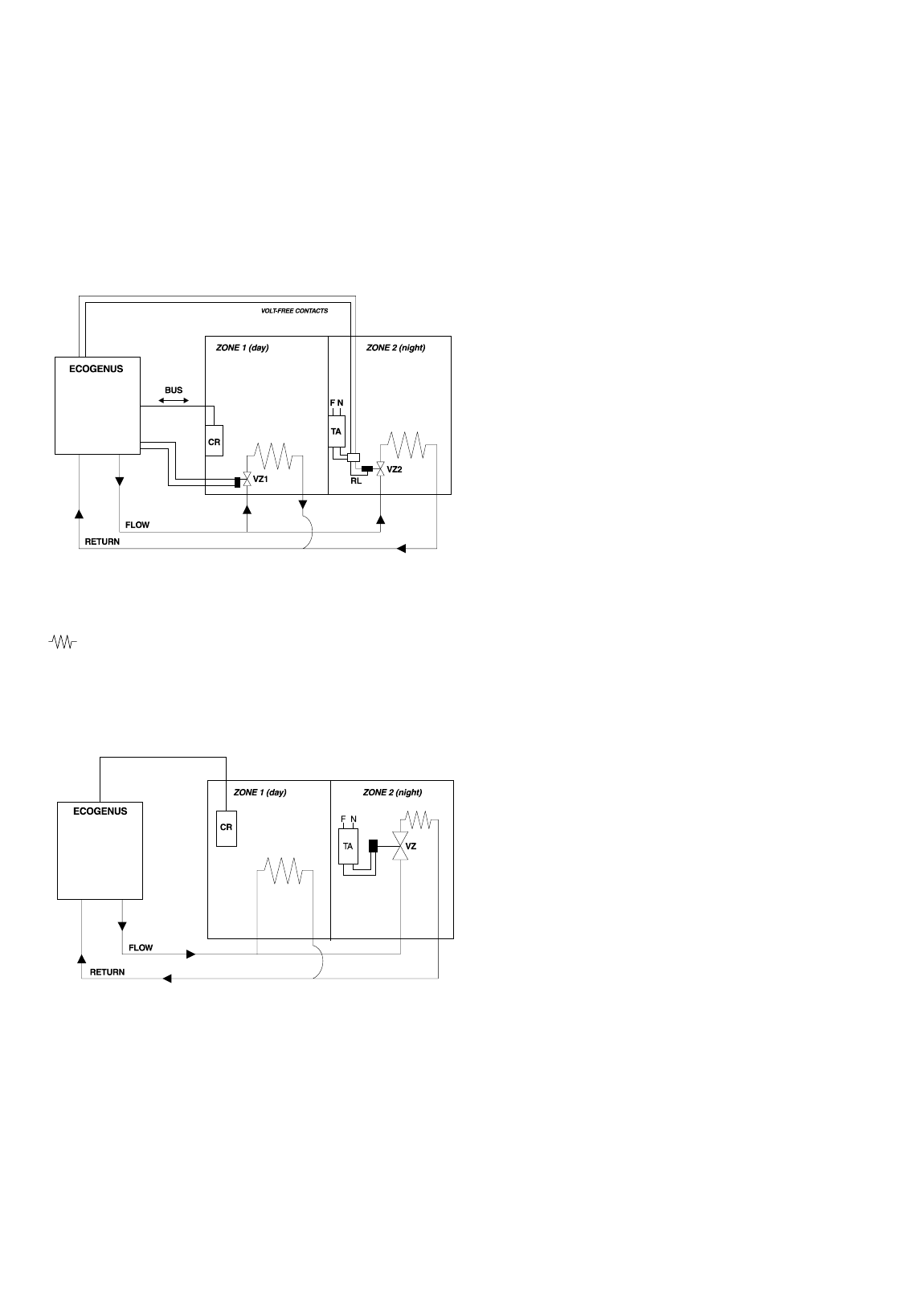

The boiler is capable of managing a heating system that uses zone

valves. The electrical connection of these valves is carried out by

means of the appropriate terminal board (indicated in the

“E

LECTRICAL CONNECTION” section).

By way of example, two possible types of systems would be:

1. System with 2 valves with independent regulation of the zones

(day and night).

2. System with 1 valve (regulation of the night zone subordinated to

that of the day).

A possible set-up for the first type of system is as follows:

5. ZONE VALVES

CR = remote control

VZ1,2 = zone valve 1 and 2

TA = roomstat or timer-thermostat

= radiators

F,N = electrical connection (live and neutral)

RL = relay

A possible set-up for the system with a single zone valve is as

follows:

This set-up is simpler and more economical because it does not

involve the use of the special relay. The night zone, however, may

only be heated during the time periods in which the remote control

timer gives consent to the heating of the day zone. Example:

• day zone programming (remote control): 8-22

• night zone programming (timer-thermostat): 20-22

6.2. C

LEANING THE P

RIMARY EXCHANGER

6.3. CLEANING THE CONDENSATE TRAP