Service manual

12

VC-A560U(A)/A560U/A560U(B)

VC-H960U/H960U(B)/H961U

VROATSV CD

11.

10. JiGDRiVER-6 BM

9. JiGDRiVERH-4 AP

4. Torque Driver JiGTD1200 CB

4. ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF MECHANICAL UNITS

The explanation given below relates to the on-site general service (field service) but it does not relates to the adjustment

and replacement which need high-grade equipment, jigs and skill. For example, the drum assembling, replacement and

adjustment service must be performed by the person who have finished the technical courses.

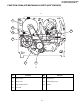

4-1 MECHANISM CONFIRMATION ADJUSTMENT JIG

So as to perform completely the mechanism adjustment prepare the following special jigs. So as to maintain the initial

performance of the machine the maintenance and check are necessary. Utmost care must be taken so that the tape is

not damaged. If adjustment needs any jig, be sure to use the required jig.

JiGTG1200 CN

JiGMP0001 BY

1. Torque Cassette Meter JiGVHT-063 CZ

No. Jig ltem Part No. Code Configuration Remarks

JiGTG0090 CM

3. Torque Gauge Head JiGTH0006 AW

JiGRH0002 BR

JiGSG2000 BS

JiGSG0300 BF

7. JiGADP003 BK

Tension Gauge

These Jigs are used for checking

and adjusting the reel disk height.

When fixing any part to the threaded

hole using resin with screw, use the

jig. (Specified torque 5 kg)

This cassette torque meter is used for check-

ing and adjusting the torque of take-up for

measuring tape back tension.

These Jigs are used for checking

and adjusting the torque of take-up

and supply reel disks.

Master Plane Jig and

Reel Disk Height

Adjusting Jig

Pinch pressing force

measuring jig

This Jig is used with the tension

gauge. Rotary transformer clearance

adjusting jig.

There are two gauges used for the

tension measurements, 300 g and

2.0 kg.

These tapes are especially used for

electrical fine adjustment.

Video Audio HiFi Audio Track

525 Monoscope 7k — 58µm

NTSC Color Bar 1k — 58µm

VROEFZCS BG

OR

VROEFZHS BH

1k

This screwdriver is used for adjusting the

guide roller height.

For X value adjustment

This Jig is used for adjustment

of tension pole.

X value adjustment

gear driver

Tension Pole

Adjustment Driver

2.3k

Black Level

(only SYNC) signal

—19µm

2.

Torque Gauge

6.

5.

8.

Alignment Tape

Guide roller height

adjustment driver