Technical data

Instructions for Use

3339135: 16th Edition : November 2009 : Subject to Modication - (A3-D-P)

AirBoss

TM

EvoluTion, AirBoss

TM

EvoluTion Plus And ProAir

TM

EvoluTion

CoMPrEssEd Air rEsPirATory ProTECTion EquiPMEnT

1

Approvals

AirBoss

TM

Evolution, AirBoss

TM

Evolution Plus and ProAir

TM

Evolution are positive pressure,

open circuit, self contained compressed air respiratory equipment certied by NIOSH/MSHA.

AirBoss

TM

Evolution, AirBoss

TM

Evolution Plus and ProAir

TM

Evolution must only be used in

conjunction with compressed air cylinders approved by NIOSH/MSHA.

For Your Safety

AirBoss

TM

Evolution, AirBoss

TM

Evolution Plus and ProAir

TM

Evolution approved equipment

incorporates Dräger pre-set, and sealed pressure reducer and balanced piston unit assemblies. Drägers’

guarantee is void should original seal caps be tampered with, removed, or broken. Correct operational

condition is only valid if Dräger service, and re-seals pressure reducer and balanced piston unit.

Use of this equipment requires wearer training, knowledge, observance of these User’s

Instructions, and compliance with National Regulations, Laws and Standards, governing the

use of respiratory equipment in the country of use.

Use equipment only for the purpose specied in this manual, or as conrmed in writing by Dräger.

Guidelines for proper use of equipment should be consistent with NFPA 1500 - standard on

Fire Department Occupational Safety and Health Program.

Trained personnel should inspect and service equipment at regular intervals and a record kept

of such inspections and servicing.

Dräger recommends a service contract be obtained from your Dräger Branch or Agent.

Contact Dräger for details of Service Contracts and Service Training Courses.

Use only original Dräger Spare Parts for service and maintenance.

Notify Dräger in the event of component fault or failure.

Use only Dräger Test Equipment for service and maintenance.

Warranty and Liability Statement

Terms and Conditions of warranty, for the AirBoss

TM

Evolution, AirBoss

TM

Evolution Plus and

ProAir

TM

Evolution, can be obtained from Dräger on request.

Responsibility for reliable function of equipment transfers to the owner or operator when serviced,

or repaired by untrained personnel, (not employed or authorised by Dräger) or when used in a

manner not conforming to its intended use.

Description

Researched and designed to meet the

specic needs of the end user, the AirBoss

TM

Evolution, AirBoss

TM

Evolution Plus and

ProAir

TM

Evolution variants utilise the same

high performance rst stage pressure reducer,

lung demand valve, carbon composite backplate

and are fully compatible with a wide range of

compressed air cylinders and facepieces.

The above variants can be tted with either a

Mechanical Gauge, Flashing Gauge or Sentinel.

Details of equipment variants and approved

accessories are available from Dräger on request.

Intended Use

AirBoss

TM

Evolution, AirBoss

TM

Evolution

Plus and ProAir

TM

Evolution positive pressure

two stage compressed air respiratory protection

equipment, used in approved cylinder, facepiece

and demand valve combinations, provide the

wearer with respiratory protection when working

in a contaminated, or oxygen decient gaseous

atmosphere.

Eective working duration of equipment is

dependant on capacity (volume) of cylinder

selected and breathing rate of wearer.

Technical Data

High Pressure Connection

2216 psi connection to CGA 346

4500 psi connection to CGA 347

Lung Demand Valve to Facepiece

Connection

Push-In - Positive Pressure with By-pass

Pressure and Flow - Equipment

Medium Pressure: 87 psi to 130 psig

Air Flow: in excess of 1000 litres/minute.

at 290 psig in excess of 500 litres/minute.

Pressure and Flow - Airline Supply

If equipment tted to independent air supply,

the following parameters should be noted:

Air Supply Pressure: 90psig to 120psig

Airline Hose Length: 5 feet to 300 feet

Note: maximum working length of hose Must

Not be made up of more than 12 individual

hose lengths.

Safety Note: Air quality Must conform to

the minimum grade requirements for Type 1

Gaseous air as dened in Compressed Gas

Association Commodity Specication for

Air, G-71 (Grade D or higher quality). Use

of airline connection by a second person,

Buddy Breather, voids NIOSH approval.

Whistle Setting (Flashing Gauge)

Whistle setting for the following pressure units

is as follows:

2216 psi Unit - setting 510 psig to 600

psig

4500 psi Unit - setting 1035 psig to 1215

psig

The activation setting of the LED’s of the

Flashing Gauge (if tted) is also within the

above setting parameters.

Weights

AirBoss

TM

Evolution, AirBoss

TM

Evolution

Plus and ProAir

TM

Evolution Self Contained

Breathing Equipment (without cylinder) -

8.5lbs.

Charged Compressed Air Cylinders

4500psi/60 minutes (Carbon composite) 19.0lbs

4500psi/60 minutes (Kevlar composite) 22.0lbs

4500psi/60 minutes

(Fibreglass composite) 26.5lbs

4500psi/45 minutes (Carbon composite)

14.8lbs

4500psi/45 minutes (Kevlar composite)

17.0lbs

4500psi/45 minutes

(Fibreglass composite) 20.6lbs

4500psi/30 minutes (Carbon composite) 11.4lbs

4500psi/30 minutes (Kevlar composite) 12.4lbs

4500psi/30 minutes

(Fibreglass composite) 13.2lbs

2216psi/30 minutes (Carbon composite)

12.0lbs

2216psi/30 minutes

(Fibreglass composite) 13.9lbs

2216psi/30 minutes

(Hoop Wrap, Fibreglass) 16.3lbs

2216psi/30 minutes (Full Aluminium) 21.4lbs

Equipment Dimensions

Data indicated is less cylinder and with carrying

harness folded in stowage condition.

Length: approx. 24.5 inches

Width: approx. 12.5 inches

Height: approx. 6 inches

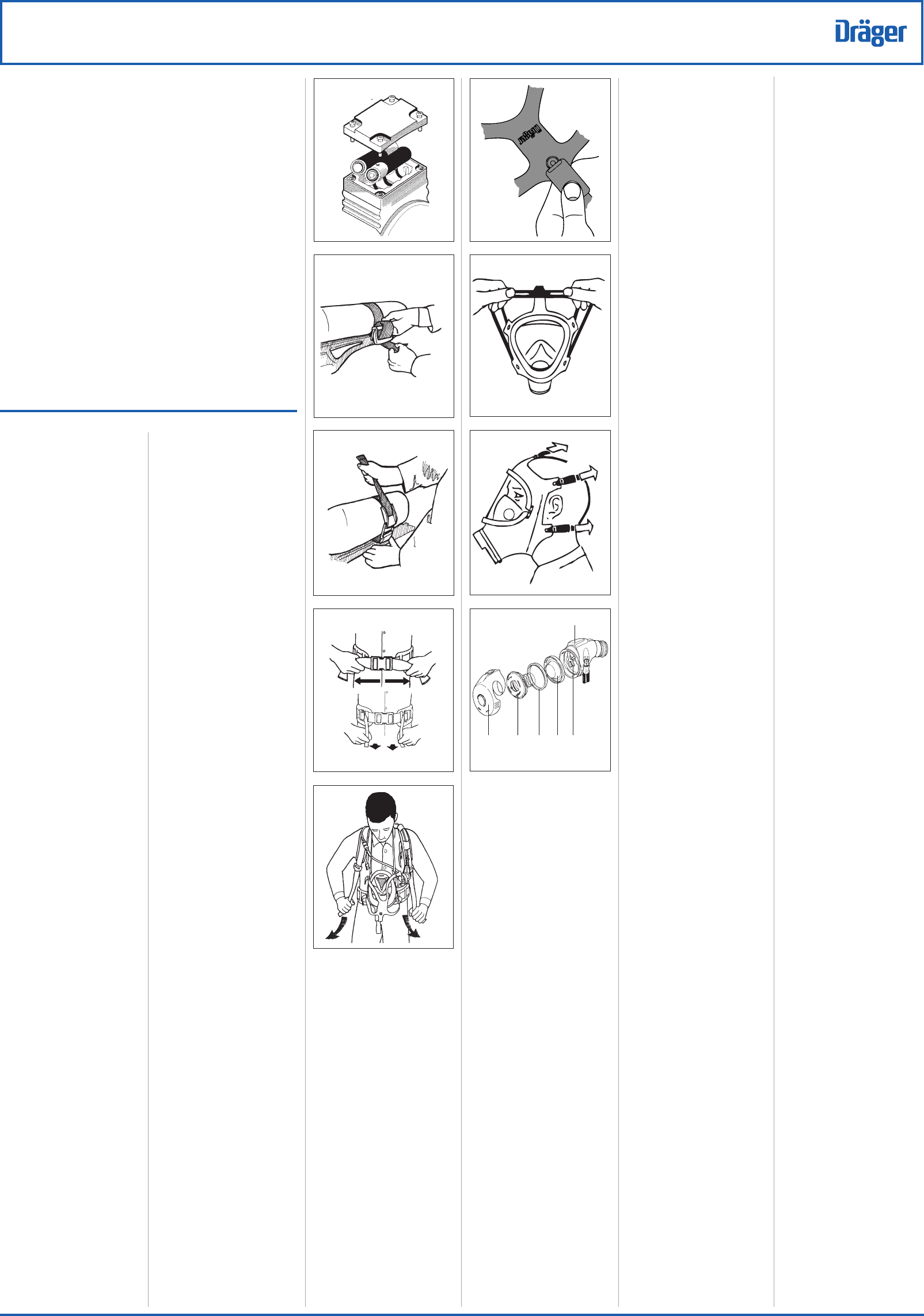

Preparation for use

Flashing Gauge - Fitting Batteries

If Flashing Gauge tted – t new batteries

as follows:

Fold back rubber cover from the gauge to

access the battery cover.

Refer to Fig. 1. Using TORX

TM

- TX 8

unscrew the four captive screws and carefully

remove the battery cover taking care not to

damage the sealing gasket.

Insert two new batteries into the battery

compartment ensuring correct positioning of

terminals.

Check that sealing gasket is not damaged.

Relocate battery cover and secure using the

four captive screws. Do Not overtighten

(max. 0.4Nm).

Reposition rubber cover over the gauge.

Fitting Cylinder

Check valve port and the reducer handwheel

threads are undamaged, connector O ring

is in position, and undamaged.

Place the backplate horizontal, extend

the cylinder strap, slide cylinder through

strap locating the valve port to the reducer

handwheel.

Lift unit upright, screw the handwheel into the

valve port, (handtight). Do Not use tools.

Place backplate horizontal, take up slack on

cylinder strap (Fig. 2) pull strap over cylinder

to activate Camlock (Fig. 3) secure strap to

Velcro.

Pre Operational Checks

High Pressure Leak Test

Press reset (1 Fig. 9) mechanism of the lung

demand valve to switch ‘O’ positive pressure.

Open the cylinder valve slowly, but fully, to

pressurise system.

Note: If an immediate leak is indicated from

the demand valve - press the centre of the

rubber cover to release the positive pressure

mechanism - press reset mechanism to

switch ‘O’ positive pressure. Repeat the

action two or three times to eliminate the

leak. If leak not eliminated return balanced

piston unit to Dräger Service.

Close the cylinder valve and observe the

pressure gauge.

Gauge reading shall not decrease more than

200psig in 1 minute.

Whistle Warning Unit Test

Cover the outlet of the demand with ball of the

hand, press the centre of the rubber cover,

turning ‘On’ positive pressure. Slowly vent

system by carefully lifting the ball of the hand

maintaining a slow decrease in pressure.

Observe the gauge. Whistle should sound

at the preset pressure.

Note: Whistle pre-set by Dräger to the

following values:

2216 psi Unit - 510psig to 600psig

4500 psi Unit - 1035psig to 1215psig

Should whistle not sound at the required

pressure, refer to Service Manual.

Important Note: The activation setting of the

LED’s of the Flashing Gauge (if tted) is also

within the above setting parameters. Audible

and visual signals/warnings may however

not activate at exactly the same time. The

LED’s of the Flashing Gauge will switch o

before the audible warning at the following

approximate values,

2216 psi Unit – below 200psig

4500 psi Unit - below 400psig

Following satisfactory whistle test, press reset

mechanism to switch ‘O’ positive pressure.

Connecting Demand Valve to

Facepiece

Check that the facepiece port and the demand

valve O ring are clean and undamaged.

Push the demand valve into the facepiece

port until it clicks into position. A slight turning

motion of the LDV during pushing will aid

connection.

Check that the attachment is secure. Pull

the demand valve away from facepiece - there

should be no axial movement.

Operation

Putting on equipment

Extend the waistbelt and shoulder adjusting

straps.

Put on equipment taking weight on

shoulders by pulling on shoulder adjusting

straps. Do Not tighten.

Fasten waistbelt buckle. Pull ends of waistbelt

adjusting straps (see Fig. 4) until waistbelt pad

is secure and comfortable on hip. Tuck strap

ends between body and waistbelt pad.

Pull down shoulder adjusting straps (Fig. 5)

until equipment is secure and comfortable.

Do Not overtighten. Tuck strap ends under

waistbelt.

Extend facepiece head harness straps, leaving

centre strap in position, (Fig. 7). Put neck

strap over neck, insert neck strap stud into

hole in centre strap of head harness.

Carry out High Pressure Leak Test.

Note: Cylinder pressure must not be less

than 80% full. If pressure is below maximum

charging pressure of the cylinder, this will

reduce available duration to the wearer.

Press the reset mechanism of the demand

valve to switch ‘O’ the positive pressure.

Open the cylinder valve slowly, but fully, to

pressurise the system. Check the gauge.

Putting on Facepiece

Safety Warning: Beards, side whiskers,

facial stubble and/or spectacle frames will

interfere with face seal of facepiece, and

adversely aect protection of the wearer.

Detach the neck strap stud from the centre

strap of the head harness.

Spread the harness, (Fig. 7) then place chin

into the facepiece, position harness over the

head locating the harness centre plate with

the back of the head.

Tighten both the lower, then the upper straps

evenly towards back of the head. Fig. 8. Tuck

in strap ends.

On achieving a face seal the positive pressure

demand valves will automatically activate on

rst breath inhalation.

Breathe normally then prior to use perform

function checks.

Function Checks

Inhale and hold breath. Unit must balance,

i.e. no audible leak.

Continue breathing. Expired air should easily

ow out of the exhalation valve.

Press the ‘red’ by-pass button of the demand

valve checking that an additional airow is

delivered into the facepiece.

Close the cylinder valve. Breathe normally to

vent the system. When the gauge indicates

zero, hold breath. Facepiece should hold

onto the face indicating a positive seal.

Note: If a leak detected, open the cylinder

valve, readjust the head harness and retest.

Open the cylinder valve slowly, but fully to

pressurise the system, recheck the pressure

gauge and proceed.

Use

Take gauge reading regularly. Whistle will

sound at whistle warning unit pressure

setting.

Proceed to safe area, at least when whistle

sounds, by shortest and safest route.

Important Note: The activation setting of the

LED’s of the Flashing Gauge (if tted) is also

within the whistle setting parameters. Audible

and visual signals/warnings may however not

activate at exactly the same time. The LED’s of

the Flashing Gauge will switch o before the

audible warning.

Safety Notes:

a. Additional Air Required

If momentary additional airow is required, press

‘red’ bypass button of lung demand valve. In the

unlikely condition of low or blocked airow, or

if required to maintain additional airow, press

and rotate the ‘red’ bypass button to ‘lock’ the

ow setting (80 - 130Litres/min). Duration of

the air supply is reduced while the bypass is

in operation. When set in this condition the

wearer must evacuate to a safe area. If it is

suspected that the apparatus is blocked then an

investigation by a trained authorised person must

be carried out before re-using the apparatus.

b. Excessive or Loss of Airow

In the unlikely condition of high or loss of

airow, close the cylinder valve then immediately

begin to slowly re-open the valve, using it as

an adjusting valve to set sucient airow to

cover the maximum inhalation requirement.

This action must only be carried out in an

emergency situation to escape to a safe area. An

investigation by a trained authorised person must

be carried out before re-using the apparatus.

Note: On SCBA having cylinders tted with

a locking (ratchet) valve, adjustment of the

cylinder valve while wearing the SCBA must

be performed as follows. Reach behind with

the left hand to support the backplate and

at the same time with the right hand, push

and hold in the valve handwheel, rotating the

handwheel clockwise to close the valve then

immediately begin to slowly re-open the valve,

using it as an adjustment valve to set sucient

airflow to cover the maximum inhalation

requirement. Release the valve handwheel

when the required airow is achieved.

Connecting to Independent Air Supply

Note: Ensure independent air supply source

meets pressure and air quality requirements

as dened in Technical Data section of this

User’s Instruction.

Turn ‘On’ the independent air supply then

connect air supply hose to the coupling of

the Buddy Breather connection.

Close equipment cylinder valve and breathe

normally from the independent air supply.

IN AN EMERGENCY - If independent air

supply ‘Fails’, proceed as follows:

Open cylinder valve slowly but fully. Breathe

normally.

Disconnect air supply hose from Buddy

Breather connection.

If necessary leave hazardous area by

shortest and safest escape route.

After Use

Safety Warning: Do Not remove equipment

until in safe area, clear of hazard.

Release the side straps of the head harness,

press the reset mechanism of the demand

valve to switch ‘O’ the positive pressure

then remove the facepiece.

Close the cylinder valve.

Unbuckle the waistbelt, lift shoulder strap

buckles to loosen, remove the equipment.

Note: Do Not drop or throw down equipment

as damage could occur.

Press centre of the rubber cover of the demand

valve to vent system. Following venting press

the reset mechanism of the demand valve to

switch ‘O’ positive pressure.

Note: If the by-pass has been set in constant

ow position, turn the ‘red’ button to unlock,

and switch ‘O’ the by-pass.

Pass equipment to the Service Department.

Routine Maintenance

To be performed after Use.

See also Maintenance and Test Intervals Chart.

Removal of cylinder

Safety Warning: Cylinder valve should be

closed and system vented.

Lift free end of the cylinder strap against the

Camlock to release, loosen the strap. Unscrew

handwheel from cylinder valve. Slide cylinder

away from reducer, remove from equipment.

Recharge the cylinder.

Charging Cylinders

Safety Warning: Air quality for compressed

air cylinders must conform to the minimum

grade requirements for Type 1 gaseous

air as defined in the Compressed Gas

Association Commodity Specication for

Air, G-7.1 (Grade D or higher quality).

To prevent ingress of moisture into the cylinder,

ensure that the cylinder valve remains ‘closed’ until

connected to the charging unit.

Dräger recommends that the moisture content in

charged cylinder should not exceed the following:

2216 psig Units

50 mg/cubic meter (4.99 x 10-5 ounce/

cubic feet.

4500 psig Units

35 mg/cubic meter (3.49 x 10-5 ounce/

cubic feet.

Safety Warning: If moisture content exceeds

recommended levels, ice particles can

form reducing, or blocking air ow. Water

content of breathing air must be checked.

Recharge to the indicated pressure stamped on

the neck, or shoulder of the cylinder.

Visual Inspection

Check integrity of:

Carrying plate.

All straps, buckles and harness.

Valves, connectors and cylinder supports.

Facepiece.

Flashing Gauge – if tted

Replace batteries annually regardless, or when the

brilliance of the LED’s is signicantly reduced.

Note: Use only approved batteries. Refer to

the specications detailed on the label of the

gauge battery cover.

Cleaning, Disinfecting, Drying

Carefully clean, disinfect, and thoroughly dry

contaminated dirty components as necessary.

Use suitable baths for containing cleaning and

disinfecting solutions. Immerse and manually

agitate components in solutions. Dräger

recommends that no form of mechanical,

electrical or ultrasonic agitation be used.

Safety Note: Refer to manufacturers’ usage

instructions when using cleaning and

disinfecting agents. It is important that

attention be paid to concentration and

reaction times. Do Not use organic solvents,

such as Acetone, Alcohol, White Spirit,

Trichloroethylene or similar.

Dräger recommends the following:

Cleaning

Dräger Safety Wash.

Do Not exceed a temperature of 86

degrees Fahrenheit.

Disinfecting

Incidur.

Do Not exceed a temperature of 86

degrees Fahrenheit.

Details of cleaning and disinfecting agents are

available from Dräger on request.

Rinsing and Drying

Remove cleaning and disinfecting solutions by

rinsing in clean water, followed by drying.

Do Not exceed a temperature of 140 degrees

Fahrenheit when drying components.

Lung Demand Valves

It is important to follow these instructions to

internally clean and disinfect the lung demand

valve.

Refer to Fig. 9.

Fold the rubber cover (2) from the front of

the demand valve body. Grip the bayonet

cap (3), turn anticlockwise and remove the

bayonet cap.

Note: The positive pressure spring remains

attached to the bayonet cap. Do Not remove,

stretch or compress the spring. Take care not

to damage the spring during cleaning and

disinfecting procedures.

Using the thumb and forenger carefully grip

centre plate of the diaphragm (4) then tilt the

centre plate and lift the diaphragm from the

body of the demand valve. Remove the slip

ring (5).

Note: The diaphragm must not be ultrasonically

cleaned as this will aect the bonded area of the

diaphragm. Clean and disinfect manually.

Fold rubber cover back over the front of the

demand valve body to protect the lever (6)

of the balanced piston.

Immerse, and manually agitate the demand

valve, diaphragm, slip ring, and bayonet cap

in cleaning uid. (Refer to cleaning uid

instructions.)

After cleaning, rinse components in clean

water.

Immerse and manually agitate components in

disinfecting uid. (Refer to disinfecting uid

instructions.)

After disinfection fold the rubber cover from the

front of the demand valve and rinse components

in clean water. Take care not to damage the lever

(6) of the balanced piston.

Connect the hose of the demand valve to a

medium pressure air supply. Press reset (1)

then turn ‘ON’ the air supply.

Gently press lever (6) blowing out fluid

residue.

Safety Note: Wear suitable eye protection.

Disconnect from air supply, dry the components

and, if necessary remove the excess uid.

After drying, carefully locate the outer bead

of diaphragm into groove in the demand

valve body.

8

1

2

3

0018

0016

6

0017

7

0584

6

4

53

9

2

1

3

0157

0156

2

1146

4

ProAir

TM

Evolution

AirBoss

TM

Evolution

0020a/0163

5

0153

1