Owners Manual

ENGINE

D/13

2

The final position

of

the

guide

is

shown in Fig.

15.

Jt must stand ft-in. (17. 0656 mm.) above the valve

spring recess in the cylinder head.

Renewing Valve Spring in Position

In

an emergency a new· valve spring can be fitted

without lifting the cylinder head,

but

it is first advisable

to bring the piston to top dead centre, thus preventing

the valve falling into the cylinder.

Remove the sparking plug, and by means

of

a screw-

driver

or

similar tool,

the

valve can be held

on

its seat

whilst the spring

is

compressed. The valve rocker shaft

can

be used as a fulcrum point by an operator using

two screwdrivers to bear on the valve spring cup each

side

of

the valve stem while the cotters are dealt with.

Distributor. To Remove and Replace .

Remove the distributor cover by releasing the two

spring clips, then disconnect the low tension wire

and

the plug leads.

Disconnect the vacuum control suction pipe

and

slacken

the

pinch bolt

of

the distributor clamping plate.

Lift

out

the

distributor.

Under

normal circumstances it will

not

be necessary

to remove the main driving spindle. Should the occasion

arise-such

as a major overhaul when the camshaft has

to

be

removed-simply

remove the clamping plate by

releasing two setpins

and

the distributor housing by

releasing one setpin. Insert a length

of

screwed

/s-in.

(7. 9375 mm.) diameter rod in the end

of

the spindle.

Withdraw the spindle

at

the same time giving the rod

a turning movement to ease removal.

On

replacement the engine must be turned until No.

1 piston

is

at

T.D.C. on

the

compression stroke, i.e.,

Nos. 7 and 8 valves

"rocking".

With the screwed

rod

still in the distributor

spindle, insert the spindle

in

the crankcase so

that

the

eccentric slot takes up a position

of

approximately

Fig. 16.

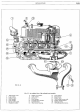

An

exploded

view

of

the distri-

butor drive.

1.

Vacuum

control

union.

2.

Distributor.

3.

Clamp

plate.

4.

Clamp

plate setpin.

5.

Bolt

for

clamp

plate.

6.

Distributor

housing.

7.

Driving

dog.

8.

Main

drive spindle.

9.

Setpin

for

housing.

10. Spindle

end.

8

H40. 293. B.

twenty past ten, the larger

portion

of

the spindle

flange being top right.

The key

of

the distributor drive coincides with the

slot

of

the spindle thus ensuring

that

the distributor

cannot be incorrectly refitted.

Ignition Timing

The correct setting for the Saloon,

Coupe

and

Commercials, using standard fuel, is 7deg. before T.D.C.

(H

in. on flywheel periphery) and, for premier fuel,

10

deg. before T.D.C.

(H

in. on flywheel periphery).

For

the Sports, using standard fuel, the setting is 2

de

g.

before

T.D.C. (

i!r

in. on flywheel periphery) and, for premier

fuel, 7 deg. before T.D.C.

(H

in. on flywheel periphery).

If

the gearbox

is

removed obtain T.D.C. for No. 1

piston on compression stroke (Nos. 7

and

8 valves

"rocking") by turning the engine with the starting handle

until the

"1

/4"

mark

on

the

flywheel

is

vertical. Make a

corresponding

mark

on

the engine backplate, also

mark

off on the flywheel the desired setting (already given)

for the fuel to be used.

Now

rotate the flywheel with

the starting handle until

on

the second revolution the

new setting

mark

coincides with the

mark

on

the engine

backplate.

Fig. 17. Showing the

method

of

removing

the

distri-

butor

driving spindle.

1.

Screwed rod.

2.

Driving spindle.