Owners Manual

ENGINE

D/15

signs

of

carbon. Remember to thoroughly

"blow-out"

the plug after treatment under these conditions, in

order

to

remove all traces

of

abrasive left inside.

After cleaning, thoroughly examine the plug for

cracked insulator or worn away insulator nose. Should

either

of

these conditions be apparent a new plug

should be installed.

Carbon

deposit

on

the threads

of

the plug should be

carefully removed by using a wire brush, or,

if

avail-

able, a wire buffing wheel. Take care

not

to

damage

the electrodes or insulator tip.

Omission

of

this cleaning

operation will lead to tight threads and the resultant

loss

of

heat

dissipation due to the carbon deposit, and

thereby causing overheating.

The condition

of

the electrodes should now be

noted and (if it

is

felt

that

the plugs are worthy

of

further use) any signs

of

corrosion removed. This can

be

carried out with the use

of

a small

file,

to carefully

dress the gap area. The gap should then be reset, using

the plug gauge provided in the tool kit. When resetting,

bend the side electrodes only, never bend the central one

as this may split the insulator tip.

If

a plug testing machine

is

available, the plugs

can be accurately tested

to

ascertain their fitness for

further service

in

the car. The plugs should be set

to

the correct gap before being subjected

to

this test.

A plug can be considered fit for further use

if

it

gives a continuous spark, when

in

the testing machine,

up

to

100

lbs.

per

square inch. Having been found satis-

factory refit to the engine.

It

is

advisable, whilst the plugs are under pressure

in the testing machine,

to

apply a spot

of

oil to the

terminal end,

to

check for

air

leakage. Excessive leak-

age here will tend to cause compression loss, rapid deter-

ioration

of

the electrode

and

overheating

of

the electrode

tip. The top

half

of

the insulator should be carefully

examined for any signs

of

paint splashes or accumu-

lations

of

grime

and

dust, which should be removed.

Should there be any signs

of

cracks due

to

faulty use

of

the spanner, the plug should be replaced.

It

is

recommended

that

plugs should normally be

replaced every 10,000 miles (16,000 km.). When replacing

the plug lead, make sure

that

it is securely attached.

Make plug inspection, cleaning

and

testing a

routine

job

and

carry this

out

at

least every 3,000 miles

(4,800 km.). Remember, plugs in good condition will

ensure better fuel consumption and good engine

performance.

REMOVING AND REFITTING

THE

ENGINE

Saloon, Coupe

Drain

the water from the system

and

then dis-

connect the battery terminals. The engine may be

drained

of

oil,

but

this

is

not

essential.

The first operation is to remove the bonnet.

To

do this, release two bolts, nuts and washers from each

hinge, then lift off the bonnet.

Release the upper water hose from the radiator

header tank,

and

the thermostat housing.

To

effect

this removal, slacken the hose clip screws

at

either end

of

the hose with the aid

of

a screwdriver

and

then ease

the rubber pipe off both the radiator and thermostat

housing connections. In a similar manner release the

lower hose from the water pump. The temperature

gauge bulb should now be removed from the radiator.

Next release the three securing bolts

at

each side

of

the radiator (see Fig.

8,

page B/5), with nuts

and

washers,

that

hold the radiator to its mounting frame.

The radiator may now be lifted from the car.

For

the removal

of

the cooling fan, simply extract

the four setpins

that

secure

the

fan to

the

water

pump

pulley.

At

the left-hand side

of

the engine,

take

off

the

air

cleaner after slackening the clamp

at

the carburetter

intake

and

releasing the breather pipe from

the

valve

rocker cover.

From

the carburetter throttle, disconnect

the operating

rod

by removing the securing

nut

and

washer

of

the ball

joint

connector

pin

and

pull the pin

clear

of

the throttle lever. Release the choke control

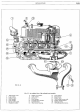

Fig.

19.

Levering over the gear change cross-shaft.

l.

Ball joint connector.

2.

Cross-shaft inner arm.

3.

Cross-shaft.

4.

Cross-shaft outer arm.

5.

Ball

joint connector.

6.

Cross-shaft outer bearing.