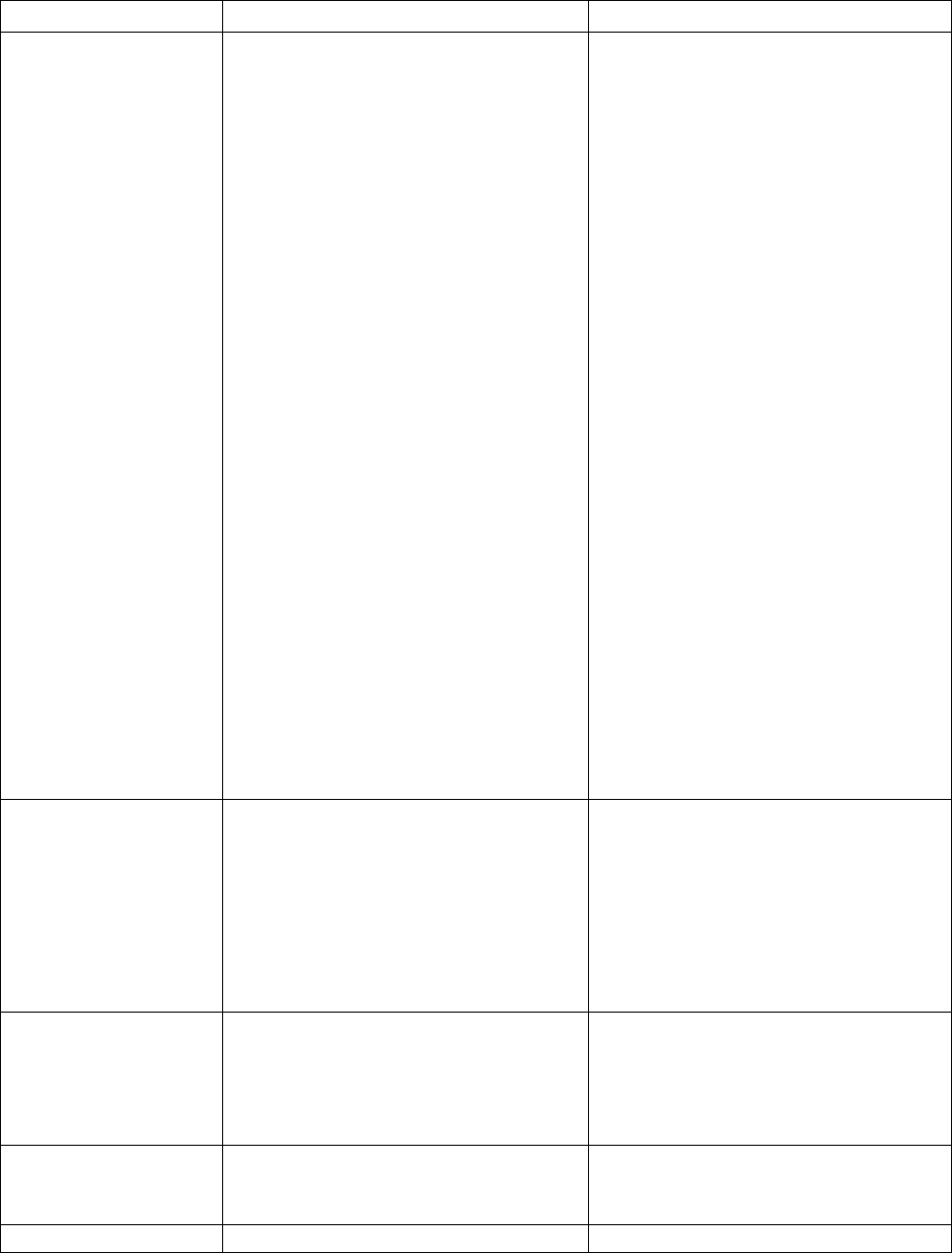

Specifications

1-13

1.10.1 ATO (Automatic Top-off) Troubleshooting

Problem Probable Causes Corrective Action

Frypots won’t top

off.

A. Probe temperature lower than

setpoint.

B. Oil is too cold.

C. ATO board power loss

D. Failed solenoid.

E. ATO pump failed or over

tightened.

F. Failed transformer/harness.

G. Failed ATO board.

A. Check to see that fryer is

heating. Fryer temperature must

be at setpoint. Check probe

resistance. If probe is bad,

replace the probe.

B. Ensure that the oil in the JIB is

above 70°F (21°C).

C. Power to the ATO board has

been cut off. Restore power to

the board and cycle ALL

computers off and on to

readdress system.

D. Check solenoid to see if

functioning properly.

E. If the solenoid is working, ensure

that the screws on the bottom of

the pump are not too tight.

Loosen the screws. If loosening

the screws doesn’t fix the

problem, replace the pump.

F. Ensure transformer in ATO box

is functioning properly. Check

power from transformer to ATO

board. Ensure all harnesses are

plugged securely into place.

G. Check for proper voltages using

the pin position chart found on

page 1-14. If ATO found

defective, replace ATO board.

The yellow JIB low

light won’t

illuminate.

A. Power in the component box is not

present.

B. Failed transformer.

C. Loose wire connection

A. Ensure power is present in the

component box.

B. If power is present in component

box, check the transformer for

correct voltage.

C. Ensure the yellow LED is

securely attached to plug J6 on

the ATO board.

One vat tops off but

other vats fail to top

off.

A. Failed solenoid

B. Loose wire connection.

A. Check power to the pump. A hot

pump suggests a failed solenoid.

B. Ensure all wiring harnesses are

securely connected to ATO

board and solenoids.

Incorrect vat tops

off.

A. Wired incorrectly.

B. Flexlines connected to wrong vat.

A. Check wiring.

B. Switch flexlines to correct vat.

Frypot tops off cold.

Incorrect setpoint Ensure setpoint is correct.