User's Manual

®

Due to continuous research, product improvements and enhancements,

Badger Meter reserves the right to change product or system specifications

without notice, except to the extent an outstanding bid obligation exists.

Copyright © Badger Meter, Inc. 2004. All rights reserved.

Please see our website at

www.badgermeter.com

for specific contacts.

BadgerMeter, Inc.

P.O. Box 245036, Milwaukee, WI 53224-9536

(800) 876-3837 / Fax: (888) 371-5982

www.badgermeter.com

Recordall

®

, RTR

®

and Read-o-Matic

®

are registered trademarks of Badger Meter, Inc. TORX

®

is a registered trademark of Camcar, Division of Textron, Inc. ADE™ and BadgerTouch

TM

are

trademarks of Badger Meter, Inc. Dow Corning

®

is a registered trademark of Dow Corning

Corporation. Novagard

®

is aregistered trademark of Novagard Silicone Compounds & Greases.

G661™ is a trademark of Novagard Silicone Compounds & Greases.

Strip-back about 1 inch of the outer insulation of the ADE™ cable,

being careful not to nick the inner conductors. Strip about ¾” of

insulation from the red and black wires; the green wire is not used

and can be cut off.

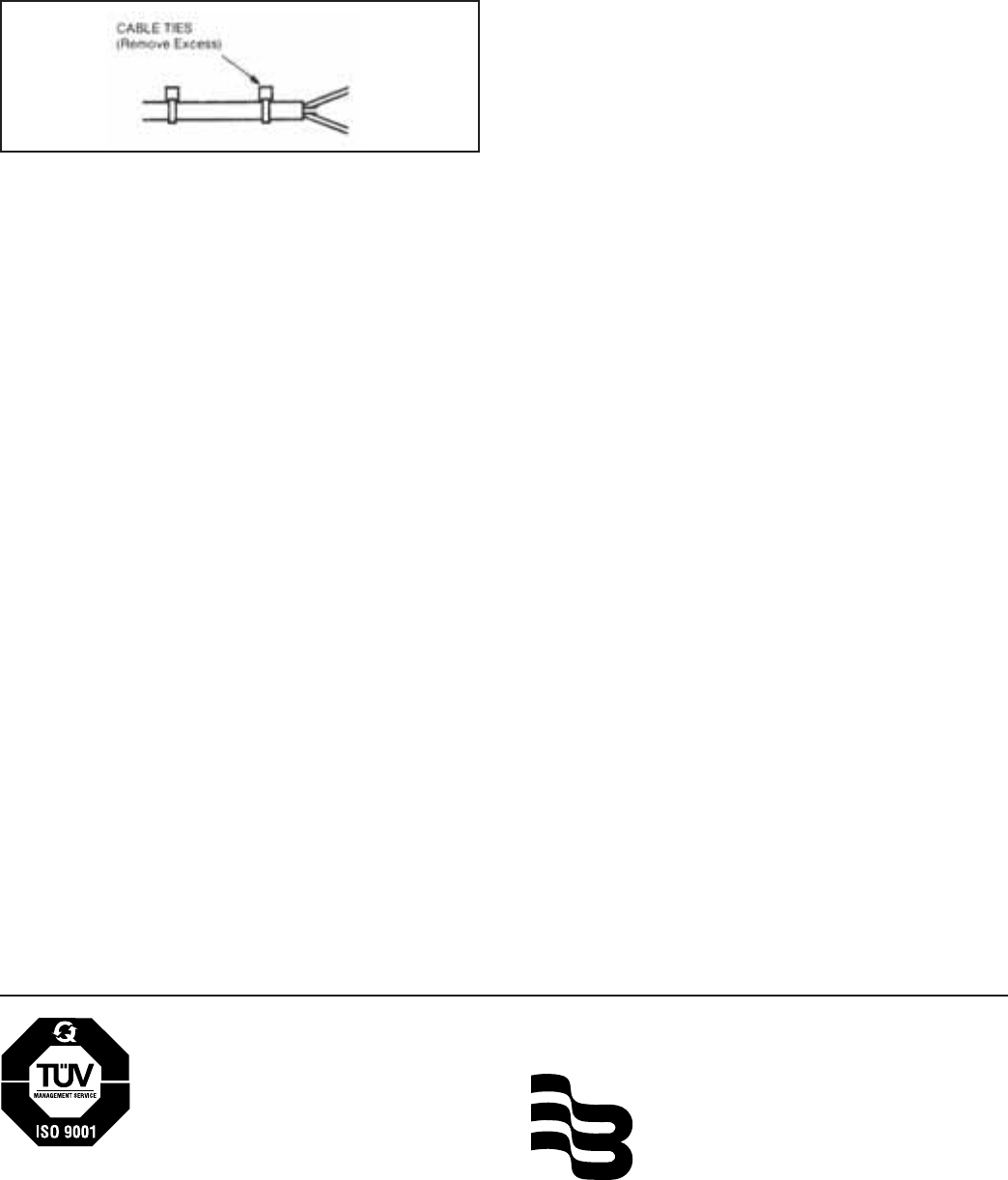

The two cable ties act as strain relief, as shown in Figure 4, to

eliminate the possibility of breaking the wire connection at the

terminals if the wire is accidentally pulled. Place the two plastic

cable ties on the outer insulation of the field wire. Tighten securely

and remove the excess cable tie with the wire cutting pliers.

Tightly wrap one bare wire around one of the terminal screws in a

clockwise direction. (Note: you can place either wire on either terminal

since the device is not polarity sensitive). The terminal screw should

then be tightened to firmly grip the wire between the screw head and

terminal. Repeat this procedure with the other wire and the other

terminal screw. Excess bare wire ends should be cut off.

If the Remote Module is to be installed in a wet or humid

environment, the terminals and exposed wires must be coated with

an approved electrical insulating compound, such as GE RTV-162

Adhesive Sealant Dow Corning

®

4 Electrical Insulating Compound

or Novagard

®

G661™. These compounds protect the terminals and

wires against corrosion which otherwise might affect the

performance and reliability of the BadgerTouch™ system.

Fasten the Remote Module to the structure using the mounting

hardware that is provided. The module must be securely mounted

to a rigid surface; avoid mounting on loose siding or any type, as

this may lead to wire breakage. Fasten the field wiring to the

building structure and/or existing piping to assure a secure

installation. Use standard fasteners or cable ties. If staples are

used, be careful not to nick or cut into the outer insulation of the

field wiring.

IF ADDITIONAL WIRE LENGTH IS REQUIRED

The ADE is supplied with a pre-determined length of wire. Should

an additional length of wire be required, it is important to follow the

instructions that are supplied with the ADE regarding splicing. Use

Belden 9770 wire. Before proceeding with the installation, be

certain that the appropriate field splice kit and gel splice crimping

tool are available to assure proper installation and that electrical

connections are secure and weather resistant.

TESTING

After all connections have been made from the remote module to the

remote cable and from the remote cable to the ADE, the testing of the

complete BadgerTouch remote system can begin. To perform the test,

a compatible reading device capable of reading Badger ADE or Sensus

protocol. can be used. The reading unit should be placed on the remote

module and the meter reading collected. This should correspond to the

reading on the meter odometer stack.

LICENSE REQUIREMENTS

The device complies with Part 15 of the FCC Rules. Operation of this

device is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undes-

ired operation. Any changes made by the user not approved by Badger

Meter can void the user's authority to operate the equipment. No

license is required by the utility to operate a BadgerTouch Meter

Reading System.

Figure 4. Strain Relief Detail