User guide

INSTALLATION MAINTENANCE

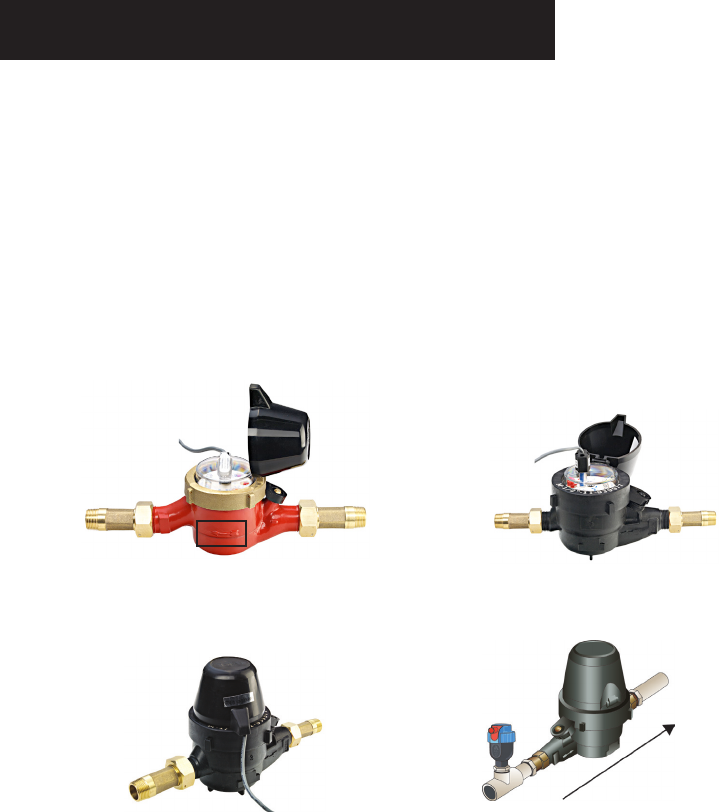

6 • ‘M’ SERIES WATER METERS

‘M’ SERIES WATER METERS • 7

MAINTENANCE REQUIREMENTS

1. Inlet side basket filter should be removed and cleaned every 90 days or as needed based on

the water quality at the site (see Figure 5).

2. Inlet side basket filter must remain in place during normal operation in order to avoid debris

entering and clogging the metering chamber.

3. Teflon tape should be used on pipe fittings and connections as needed to prevent leaks.

WARNING:

Units must not be subjected to system ‘blow out’ using compressed air. Subjecting the water

meter to this procedure will result in product failure and the resulting damage is not covered under

warranty. It is recommended that the water meter be installed in systems or portions of systems

that will gravity drain for winterization only.

If the unit is installed in a system which will be winterized with compressed air, please do one of

the following:

Install manual ball valves on each side of the water meter to isolate the water meter

from the system blow out procedure. Close the manual ball valve on one side of the

water meter, perform the blow out procedure and then open the manual ball valve.

Repeat process on the other side.

Remove the water meter before the blow out procedure and replace it with a section of

PVC/Polyethylene tubing. When the blow out procedure is complete, reinstall the water

meter.

FIGURE 5

Cleaning Inlet Side

Basket Filter

Inlet Side

Basket Filter

REGISTER REMOVAL AND INSTALLATION

1. Pry the tamper-proof tab upward using a screwdriver.

2. Loosen and unscrew the brass or plastic closing ring and cap assembly that secures the register.

Lift off the closing ring and cap assembly. Lift out the register from it’s sealed compartment making

note of the position for any spacers and o-rings.

3. To install, place the register into the sealed compartment (including spacers and o-rings) and

place the closing ring and cap assembly on top of the register. Tighten the closing ring by twisting

until secure.

INSTALLATION REQUIREMENTS

1. Correct direction of flow is indicated on the water meter body (see Figure 1).

2. Dial face must be horizontal and facing upwards (see Figure 2).

3. Register lid must be in the closed position during normal operation (see Figure 3).

4. There are no straight pipe installation requirements. If possible 5” of straight pipe upstream

(before the meter) and 2” of straight pipe downstream (after the meter) is recommended to

achieve the best performance and accuracy.

5. Prior to water meter installation, the pipeline should be thoroughly flushed.

6. The water meter must be installed so that the pipe will be full of water at all times during metering.

7. Installation of a Continuous Acting Air Vent before the water meter is highly recommended to

eliminate air and ensure accurate flow readings (see Figure 4). For additional details on air vent

options and installation requirements, refer to the Netafim USA Landscape & Turf Catalog.

FIGURE 2

Dial face upwards

↑

FIGURE 4

Air vent installation

Continuous

Acting Air Vent

Water Meter

Water Flow

‘M’ SERIES WATER METER WARRANTY

Netafim ‘M’ Series Water Meters are individually tested, calibrated and inspected to ensure they

meet the highest quality standards and the testing documents are included with each meter. They

also have the industry’s longest warranty.

3 YEARS

5 YEARS

METERING COMPONENTS

(REGISTER & METERING ASSEMBLY)

METER BODY

WARRANTY

FIGURE 1

Direction of flow

indicated on body

↑

FIGURE 3

Register lid closed