Technical data

Page 4

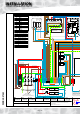

DESIGN

INTRODUCTION

gulley or else issue externally at ground level.

High level termination from walls or on roofs

could cause injury to people or animals below

if the valve were to release scalding water and

steam.

The pipe leading to the safety device and

the collector should be of rigid and non-

deformable construction, without any possibility

of restriction or disclosure by any other fitted

component.

In order to meet the Building Regulations

requirement to reduce the rate of accumulation

of scale in hard water areas, it is important

that the installer checks the hardness of the

incoming water supply.

If this exceeds 200ppm (mg/l), we recommend

that the factory fitted scale inhibitor is ordered

as an optional extra.

If it exceeds 300ppm (mg/l), we recommend the

use of a polyphosphate type of scale inhibitor.

This can also be ordered as an optional extra but

will need fitting on site by the installer.

Note:

If the summer towel rail circuit is required, this

will need to be a separate zoned circuit from the

heating circuit complete with its own time and

temperature controls.

The standard manual fill model BoilerMate A-

Class SP SOL appliance is shown. A ballvalve and

overflow are available as an optional extra at the

time of order. If required, these should be fitted

in the plain F&E cistern in a position to suit the

individual site conditions.

Model Selection Data Table/Weights

Model Reference

BMA

200 SP

SOL

BMA

220 SP

SOL

BMA

240 SP

SOL

BMA

260 SP

SOL

BMA

280 SP

SOL

BMA

300 SP

SOL

Dwelling

type

Bedrooms 2-3 2-4 3-5 3-5 4-5 5-6

Bathrooms 1 2 2 2 2 3

En-Suite 2 1 2 3 3 3

Max Floor Area (m

2

) 80 100 130 170 220 280

Weight

Empty (kg) 73 79 96 104 112 120

Full (kg) 233 260 313 366 411 472

Volume

Total (l) 160 181 217 262 299 352

Solar (l) 82 93 109 127 148 167

Note:

It is important that the maximum floor area is not exceeded to achieve compliance

with the SAP regulations.