Technical data

Table Of Contents

6 720 611 449 GB (03.11)

Maintenance

43

B Undo pipe unions by withdrawing the clips.

B Remove 3-way valve.

Fig. 58

After refitting:

B Fill system, bleed and re-pressurise

(see Installation Instructions).

9.3.5 3-way diverter valve motor

B Switch off the appliance.

B Turn off the service cocks.

B Unplug connector from 3-way valve motor. Refer to

fig. 58.

B Pull out retaining clip.

B Remove motor.

9.3.6 Sensors

B Check that the appliance is electrically isolated.

Central Heating Flow Temperature Sensor –

Item 36, fig. 2, 54

B Pull-off the connector.

B Release the sensor clip and withdraw the sensor.

B Apply heat transfer paste to the replacement sensor.

Safety Temperature Limiter – Item 6, fig. 2, 54

B Pull-off the connectors.

B Unscrew the sensor.

Flue Temperature Limiter – Item 9, fig. 2, 54

B Pull-off the connectors.

B Unscrew the sensor.

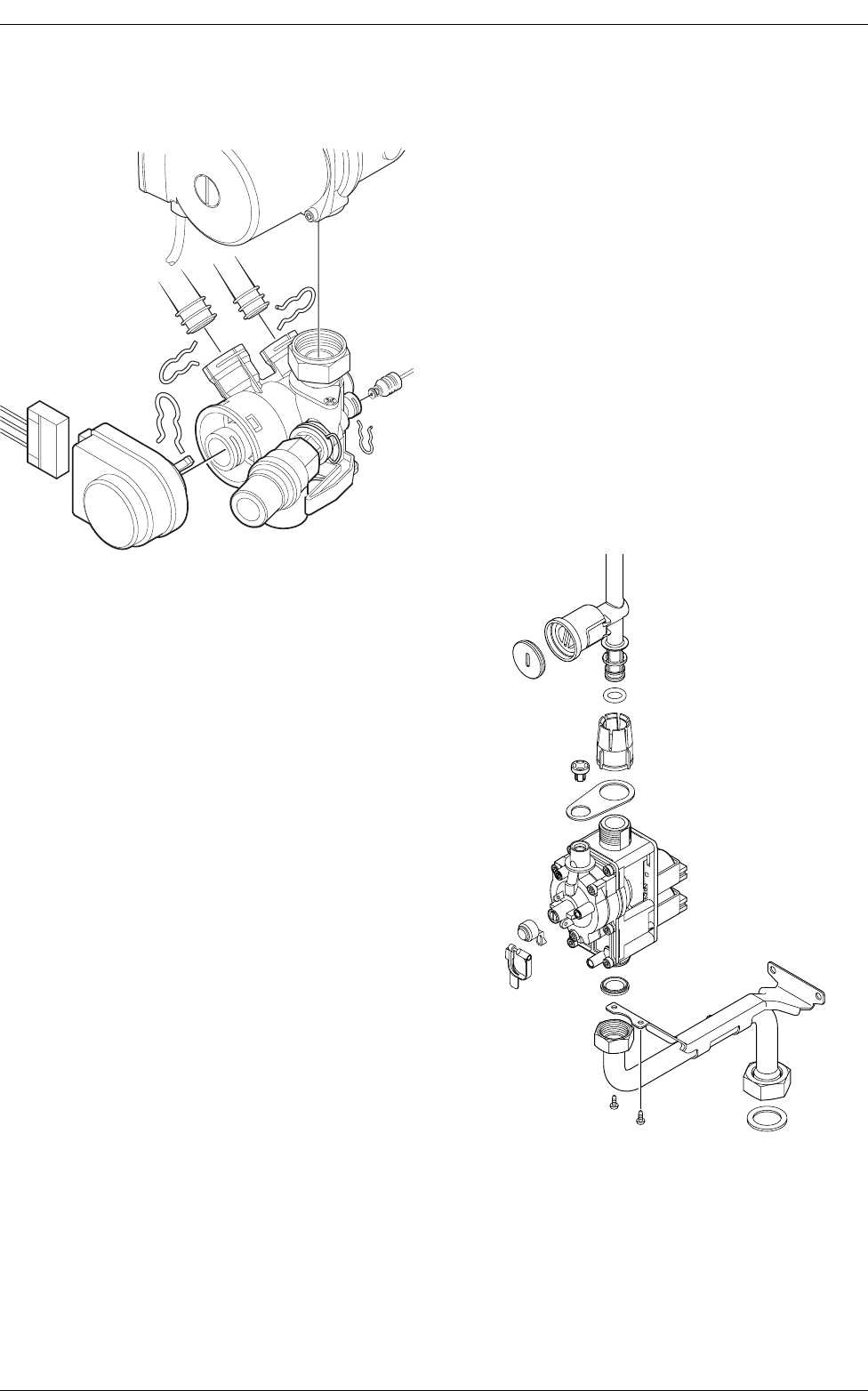

9.3.7 Gas Valve

B Check that the gas cock is turned off.

B Lower the control panel. Refer to fig. 57.

B Pull off the solenoid connections at the rear of the

valve.

B Undo the union, within the inner casing, securing the

valve to the gas/air tube. Refer to fig. 56.

B Remove the white plastic cap from the gas valve.

B Release the gas inlet union at the manifold assembly.

B Unscrew the two screws securing the gas valve

assembly bracket to the back panel and withdraw the

assembly.

B Transfer the bracket and inlet pipe assembly to the

new gas valve.

B Check for gas soundness when the new gas valve

has been fitted.

B Recheck the combustion performance as described

in section 8.1.

Fig. 59

7 181 465 330-12.1

R

6 720 610 602 - 04.1O