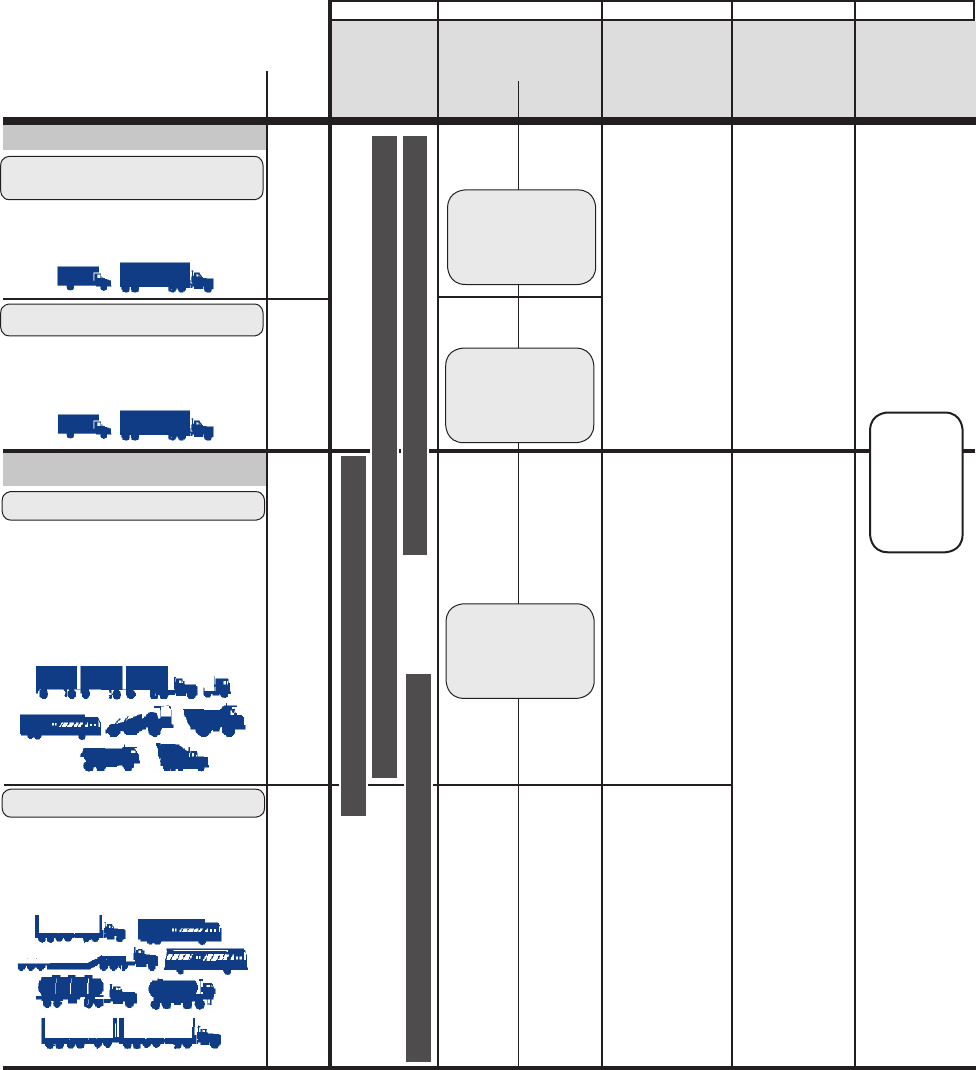

Technical data

13

Compressor with up to 25% duty cycle

Footnotes:

1. With increased air demand the air dryer cartridge needs to be

replaced more often.

2. Use the drain valves to slowly drain all reservoirs to zero psi.

3. Allow the oil/water mixture to fully settle before measuring oil

quantity.

4. To counter above normal temperatures at the air dryer inlet, (and

resultant oil-vapor passing upstream in the air system) replace the

discharge line with one of a larger diameter and/or longer length.

This helps reduce the air's temperature. If sufficient cooling occurs,

the oil-vapor condenses and can be removed by the air dryer.

Discharge line upgrades are not covered under warranty. Note:

To help prevent discharge line freeze-ups, shorter discharge line

lengths or insulation may be required in cold climates. (See Bendix

Recom- Recom- Acceptable

Typical Discharge mended mended Reservoir

Compressors Line Air Dryer Reservoir Oil Contents

3

No. of Spec'd Cartridge Drain at Regular

Axles Replacement

1

Schedule

2

Drain Interval

High Air Use

Low Air Use

e.g. Double/triple trailer, open

highway coach/RV, (most)

pick-up & delivery, yard or

terminal jockey, off-highway,

construction, loggers, concrete

mixer, dump truck, fire truck.

e.g. Line haul single trailer

w/o air suspension, air over

hydraulic brakes.

e.g. Line haul single trailer

with air suspension,

school bus.

5

or

less

5

or

less

8

or

less

12

or

less

Table A: Maintenance Schedule and Usage Guidelines

Recom-

mended

Every

Month -

Max of ev-

ery 90 days

Every

Month

Every 3

Years

Every 2

Years

Every

Year

I.D.

Vehicle Used for:

Column 1

Column 2 Column 3 Column 4 Column 5

Regularly scheduled maintenance is the single most important factor in maintaining the air brake charging

Length

6 ft.

1/2 in.

9 ft.1/2 in.

12 ft.

1/2 in.

3/4 in.

12 ft.

BASIC test

acceptable

range:

5 oil units

per month.

See

appendix

A.

For oil carry-over

control

4

suggested

upgrades:

5/8 in. 15 ft.

For oil carry-over

control

4

suggested

upgrades:

5/8 in. 9 ft.

For oil carry-over

control

4

suggested

upgrades:

5/8 in. 12 ft.

Compressor with less than 15% duty

cycle

Compressor with up to 25% duty cycle

Compressor with up to 25% duty cycle

Bendix

®

BA-921

®

air compressor

Bendix

®

Tu-Flo

®

550 air compressor

Bendix

®

Tu-Flo

®

750 air compressor

Bendix

®

BA-922

®

, or DuraFlo

™

596

air compressor

BASIC test

acceptable

range:

3 oil units

per month.

See

appendix

A.

For the

BASIC

Test Kit:

Order

Bendix

P/N

5013711

e.g. City transit bus, refuse,

bulk unloaders, low boys,

urban region coach, central

tire inflation.

(See footnote 7)

Bulletins TCH-08-21 and TCH-08-22, included in Appendix B, for

more information.)

5. For certain vehicles/applications, where turbo-charged inlet air is

used, a smaller size compressor may be permissible.

6. Note: Compressor and/or air dryer upgrades are recommended

in cases where duty cycle is greater than the normal range (for

the examples above).

7. For correct compressor upgrades consult Bendix - Please note

that because a compressor is listed in the same area of the chart

does not necessarily mean that it would be a suitable candidate

for upgrade purposes.

For Bendix

®

Tu-Flo

®

550 and 750 compressors, unloader service is

recommended every 250,000 miles.