Technical data

4

A supply of clean air is one of the single most important

factors in compressor preventive maintenance. Since the

BA-922

®

compressor receives supply air from the engine

air filter, periodic maintenance of the engine air filter is

necessary.

Inspect the compressor intake adapter, and the connecting

hoses each time engine air cleaner maintenance is

performed.

1. Inspect the intake hose adapters for physical damage.

Make certain to check the adapters at both ends of the

intake hose or tubing.

2. Inspect the intake hose clamps and tighten them if

needed.

3. Inspect the intake hose or line for signs of drying,

cracking, chafing and ruptures and replace it as

necessary.

COMPRESSOR COOLING

Inspect the compressor discharge port, inlet cavity and

discharge line for evidence of restrictions and carbon

build-up. If more than 1/16" of carbon is found, thoroughly

clean or replace the affected parts. Since carbon buildup

generally indicates inadequate cooling, closely inspect the

compressor cooling system. Check all compressor coolant

lines for kinks and restrictions to flow. Minimum coolant

line size is 3/8" I.D. Check coolant lines for internal clogging

from rust scale. If coolant lines appear suspicious, check

the coolant flow and compare to the tabulated technical

data in the back of this manual. Carefully inspect the air

induction system for restrictions.

LUBRICATION

Check the external oil supply line for kinks, bends, or

restrictions to flow.

Supply lines must be a minimum of 3/16"

I.D.

Refer to the tabulated technical data in the back of this

manual for oil pressure minimum values.

Check the exterior of the compressor for the presence of

oil seepage and refer to the TROUBLESHOOTING section

for appropriate tests and corrective action.

OIL PASSING

All reciprocating compressors pass a minimal amount of

oil. Air dyers will remove the majority of oil before it can

enter the air brake system. For particularly oil sensitive

systems, the Bendix

®

PuraGuard

®

system filter can be used

in conjunction with a Bendix air dryer.

If compressor oil passing is suspected, refer to the

TROUBLESHOOTING section and TABLE A for the

symptoms and corrective action to be taken. In addition,

Bendix has developed the “Bendix Air System Inspection

Cup” or BASIC kit to help substantiate suspected excessive

oil passing. The steps to be followed when using the

BASIC kit are presented in APPENDIX A at the end of the

TROUBLESHOOTING section.

COMPRESSOR DRIVE

Check for noisy compressor operation, which could indicate

excessive drive component wear. Adjust and/or replace

as necessary. Check all compressor mounting bolts and

retighten evenly if necessary. Check for leakage and

proper unloader mechanism operation. Repair or replace

parts as necessary.

COMPRESSOR UNLOADER & GOVERNOR

Test and inspect the compressor and governor unloader

system for proper operation and pressure setting.

1. Check for leakage at the unloader port. Replace leaking

or worn o-ring.

2. Make certain the unloader system lines are connected

as illustrated in Figure 3.

3. Cycle the compressor through the loaded and unloaded

cycle several times. Make certain that the governor cuts

in (compressor resumes compressing air) at a minimum

of 105 psi (cut-out should be approximately 15-20 psi

greater than cut-in pressure). Adjust or replace the

governor as required.

4. Note that the compressor cycles to the loaded and

unloaded conditions promptly. If prompt action is not

noted, repair or replace the governor and/or repair the

compressor unloader.

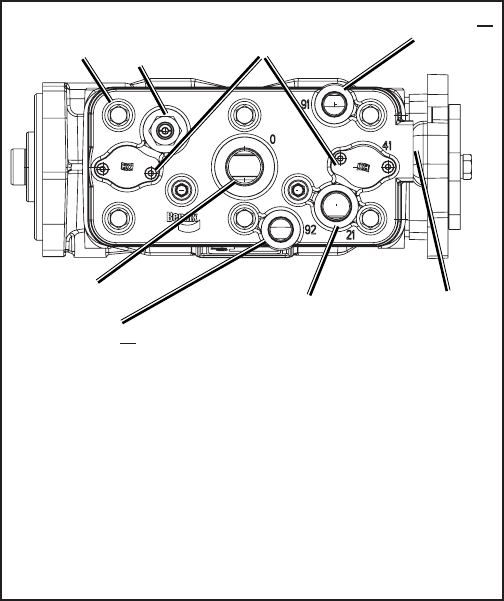

FIGURE 8 - TYPICAL BA-922

®

COMPRESSOR CYLINDER

HEAD

CYLINDER HEAD PORT IDENTIFICATION

The cylinder head connection ports are identified with cast

in numerals as follows:

Atmospheric AIR IN 0

Compressed AIR OUT 21

Coolant IN or OUT 91 and 92

Governor Control 41

(Compressors with no signal line to the unloader port should

have a vent installed in the port rather than a plug.)

Coolant In or

Out

Governor

Connection

Discharge

Safety Valve

Discharge

Port

Inlet Port

Unloader

Covers

Coolant In or Out

Head

Bolt (6)