User manual

Table Of Contents

Page 21 of 51 Vetta Head Assembly Instructions Rev D1

The PCB Screws must now be tightened the rest of the way. They should be tightened to a

torque of 6 in-lbs.

Note: These screws must be left loose until this step for 3 main reasons: (1) It is the easiest

way to get all of the screws to line up. (2) It will help prevent cracking in the solder joints

on the jacks and (3) it will ensure grounding points will make electrical contact with the

chassis.

FYI: If the PCB screws are tightened prior to inserting and tightening the back panel

screws, the fixed board may not align properly, creating high shear stress on the jack pins.

Conversely, if the PCB screws have not been placed and finger tightened to rough locate

the board prior to the back panel screws, there is a possibility of misalignment with the

PEMS. Forcing this misalignment back into alignment while the back panel screws are

tight will have the same effect of heightening shear stress on the jack pins and may crack

the solder joints.

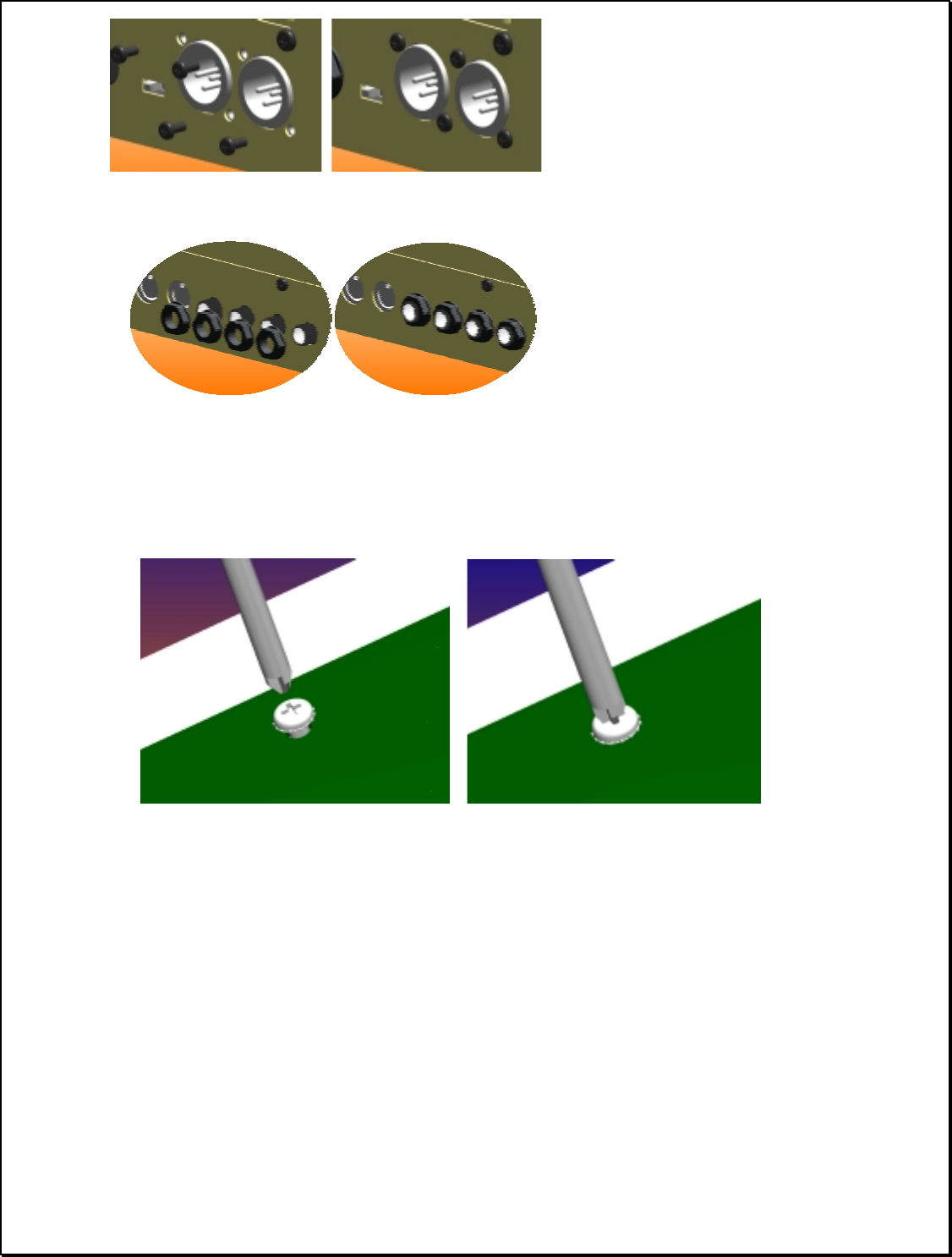

(4) #4 tapping screws (30-

00-4250) hold the XLR

jacks to the back panel.

Flush the jacks with the

back panel, insert the

screws, and tighten to 4

in-lbs.

(4) Plastic jack nuts

should be placed next.

Flush the jacks with the

b

ack panel, insert the nuts,

and tighten to 4-5 in-lbs.