User Manual

Brooks

®

Model 5850i

3-8

Section 3 Operation

Installation and Operation Manual

X-TMF-5850i-MFC-eng

Part Number: 541B108AAG

December, 2008

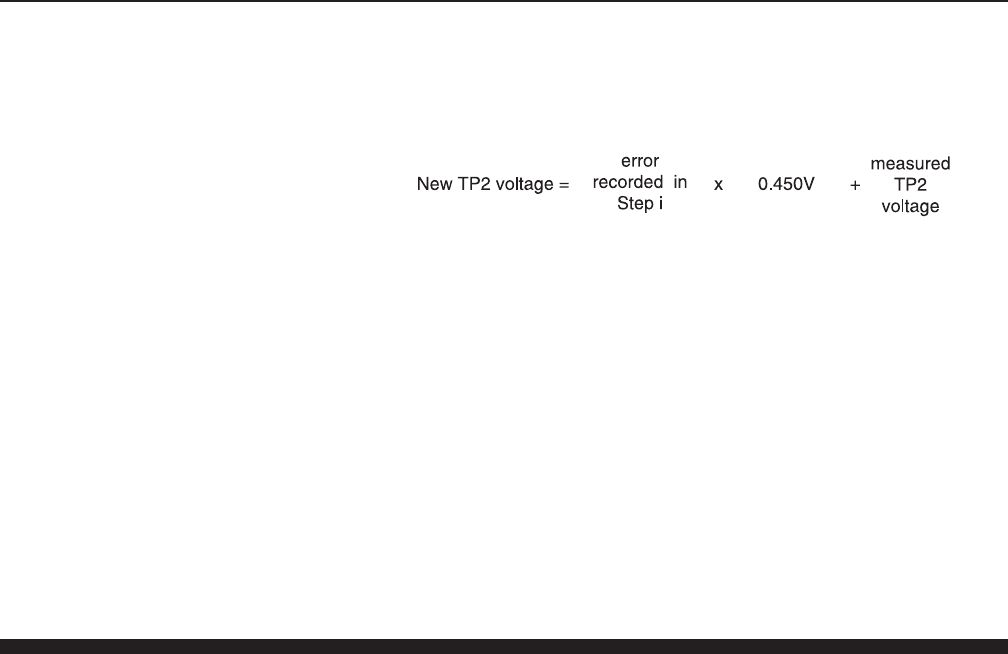

2. If the error is greater than 0.5% set the command potentiometer for

100% (5.000V). Connect the DVM positive lead to TP2 (linearity

voltage) and the negative lead to TP4 (circuit common). Calculate a

new TP2 voltage as follows:

Example:

Controller error = 0.7%

Measured TP2 voltage = -0.567 volts

TP2 correction = 0.7 x 0.450 = 0.315 volts

New TP2 correction = 0.315 + (-0.567) = -0.252 volts

Adjust the linearity potentiometer for an output equal to the new TP2

voltage and then repeat steps f, g and h.

NOTE: The voltage at TP2 can range from -10 to +3 volts, however, it is

recommended that this voltage stays between -2.5 and +2.5 volts for proper

operation. If the recommended voltage range is exceeded, the desired

accuracy and/or signal stability may not be achieved. If one of the limits is

reached, check the restrictor sizing. Refer to Section 4-7.

3-5 Response

Fast Response Adjustment

Two methods of adjusting the step response of the 5850i mass flow

controllers can be used.

Method Number 1 describes a procedure that will get the step response

close to optimum quickly and without any flow measuring equipment.

This method should be used when the response time of the flow

controller is not critical to overall system performance.

Method Number 2 describes a procedure that will allow adjustment of your

5850i mass flow controller to optimum step response performance.

This method is the preferred way to adjust the step response. Adjust-

ment of the fast response circuit will not affect the accuracy of the flow

controller as adjusted in Section 3-4.

1. Fast response adjustment (six seconds response specification not

guaranteed)

NOTE: This procedure requires an oscilloscope, chart recorder or a DVM

with a sample speed of three samples per second or greater to monitor the

rate of change of the output signal.

a. Adjust the setpoint for 100% flow and wait about 45 seconds for the

flow output signal to stabilize.

b. Step the command signal to 0% or activate valve override closed to

stop the flow. Observe the flow signal output as it decays.

c. The behavior of the flow signal during this transition between 100%