Install Instructions

65

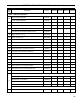

TABLE 7: BECKETT AFG BURNER SPECIFICATIONS

Boiler

Model

Burner

Input

(gph)

Head Type

(setting)

Air Shutter

(setting)

Air Band

(setting) Nozzle

Pump

Pressure

(psi)

Approx.

Shipped

CO

2

(%)

Bafe

Location

(pass)

Approx.

Stack Temp.

Increase

Without

Bafes

(F)

2

Bafes

IN

Minimum

Breech

Pressure

("w.c.)

3

Bafes

OUT

Minimum

Breech

Pressure

("w.c.)

3

Bafes

IN

Minimum

Overre

Pressure

("w.c.)

3

Bafes

OUT Minimum

Overre Pressure

("w.c.)

3

MST288 0.75 L1 6

1

1

0.60 x 60A

Delavan

150 11.5 --- --- 0 0 --- 0.010

MST396 1.05 L1 7 1

0.85 x 60B

Delavan

150 11.5 2nd 20 0 0 0.040 0.020

MST513 1.35 V1 (0) 7 2

1.10 x 60B

Hago

150 11.5 2nd 40 0 0 0.040 0.030

MST629 1.65 V1 (3) 7 2

1.35 x 60B

Hago

150 11.5 2nd 52 0 0 0.050 0.030

Notes

1)

MST288 at 0.75 GPH ring rate utilizes a low re bafe.

2)

The increased stack temperature with the bafes removed is an approximation, based on a constant supply temperature of 212°F and 11.5% CO

2

. Actual eld conditions may be different.

3) These values are minimum and could be as much as -.03" w.c., more without impacting performance. Pressures based on 11.5% CO

2

. Example: MST629 could have a breech pressure of -.03" w.c. and an

overre pressure of .020" w.c.

4) Single stage fuel pump is standard, two stage fuel pump is optional. Burner manufacturer has preset single stage fuel pump to settings shown in table above.

Two stage fuel pump is factory set at 140 PSI and must be readjusted to settings shown above during burner start-up.

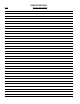

TABLE 7A: RIELLO BURNER SPECIFICATIONS

SECTION XII: REPAIR PARTS (continued)

Boiler

Model

Burner

Model

Burner

Input

(GPH)

Nozzle

Air Gate

(setting)

Turbulator

(setting)

Pump

Pressure

(PSI)

Combustion

Head

Insertion

Depth

(Inch)

Approx.

Shipping

CO

2

(%)

Bafe

Location

(Pass)

Approx. Stack

Temp Increase

without Bafes

(°F)

(1)

Bafes IN

Min. Breech

Pressure

("w.c.)

(2)

Bafes OUT

Min. Breech

Pressure

("w.c.)

(2)

Bafes IN

Min. Overre

Pressure

("w.c.)

(2)

Bafes OUT

Min. Overre

Pressure

("w.c.)

(2)

MST396 F5 1.05

0.85 x 60°B

Delavan

2.7 1.0 145 LBT 10.0" 10.0 11.5 2nd 65 0 0 0.040 0.020

MST513 F5 1.35

1.10 x 60°B

Delavan

4.5 3.0 150 SBT 6" 3.5 11.5 2nd 39 0 0 0.040 0.030

MST629 F5 1.65

1.35 x 60°B

Delavan

3.5 4.0 145 VSBT 2.25 11.5 2nd 18 0 0 0.050 0.030

1

The increased stack temperature with the bafes removed is an approximation based on a constant supply temperature of 180°F and 11.5% CO

2

. Actual eld conditions may be different.

2

These values are minimum and could be as much as -.03" w.c., more without impacting performance.

Pressures based on 11.5% CO

2

. Example: MST629 could have a breech pressure of -.03" w.c. and an overre pressure of .020" w.c.