Operating instructions

6

SECTION I — GENERAL INFORMATION

1. GENERAL INFORMATION

The boiler is designed specically for forced draft ring,

is available with oil, gas or combination gas/oil burners,

and operates with a combustion efciency of over 80%.

This manual gives the necessary information for the

proper installation, operation, maintenance and service of

units. For special installation problems, contact Burnham

Commercial, P.O. Box 3939 Lancaster, PA 17604, Phone:

888-791-3790 .

2. INSPECT SHIPMENT carefully for any signs of

damage.

A. All Equipment is carefully manufactured,

inspected and packed. Our responsibility ceases

upon delivery of boiler to the carrier in good

condition.

B. Any Claims for damage or shortage in shipment

must be led immediately against the carrier by

the consignee. No claims for variances from, or

shortage in, orders will be allowed by the

manufacturer unless presented within sixty

(60) days after receipt of goods.

3. SETTING THE UNIT

Most boilers are equipped with lifting lugs to be used

in maneuvering the boiler into position. On large boilers,

where four lifting lugs are supplied, all four lugs should be

used when lifting the boiler. Scotch boilers can also be rolled

into position using roller skids under the leg supports, pipe

rollers may cause damage. The unit should be located in the

boiler room so as to provide ease of venting and adequate

clearance for maintenance, serviceability and installation

of piping.

The tube pull space listed in the Burnham Commercial

product catalog must be provided at the front of the boiler.

The coil pull space must be maintained at the front of units

equipped with tankless coils. Floor construction should

have adequate load bearing characteristics to bear the

weight of the boiler lled with water. A boiler foundation

is recommended if the boiler room oor is weak, uneven

or if a water condition exists. These boilers are not for

installation on combustible ooring. If desiccant package

was ordered, be sure to remove from the boiler furnace

using the rear access, and from the waterside using the

manhole cover.

4. CHIMNEY OR VENT

On installations where a natural draft stack is used,

causing high breeching drafts, the boiler locking blade

damper (on boilers equipped with one) may require

adjusting, or one may need to be installed at the boiler

breeching. In multiple boiler installations, or in installations

where the breeching draft may vary considerably, automatic

draft controls in combination with a motorized damper may

be required.

When considering the stack and breeching, the design

should take into account that the boiler/burner combination

will work best when the pressure at the boiler ue outlet is

in the range of + or - 1/10 inch WC.

5. AIR SUPPLY

A sufcient air supply must be maintained at all times

to the boiler room for proper performance of the unit. A

permanent opening or duct should be provided so that

the boiler input will not exceed 4,000 Btuh/in

2

of free area.

Example: Firing Rate (Gas) = 528 MBH

528,000 BTUH = 132 In

2

Free Area

4,000 BTUH/In

2

Follow local building codes if they exceed these minimum

requirements.

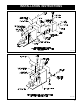

FRONT

OF

BOILER

SMOKEPIPE - DO NOT REDUCE BELOW

SIZE OF COLLAR ON REAR

SMOKEBOX

THIMBLE

FIGURE 1

TYPICAL ARRANGEMENT FOR STUB VENT

TS-71-129-B