Product Manual

Installation (Continued)

WIRING

All wiring

and electrical

connections must be performed by

a qualified electrician. Installations

must be in accordance with local

and national codes.

Overheating, short

circuiting and fire

damage will result from inadequate

wiring.

Wiring must be installed in accordance

with National Electrical Code and local

codes and standards that have been set

up covering electrical apparatus and

wiring. These should be consulted and

local ordinances observed. Be certain

that adequate wire sizes are used, and

that:

1. Service is of adequate ampere

rating.

2. The supply line has the same

electrical characteristics (voltage,

cycles and phase) as the motor.

3. The line wire is the proper size

and that no other equipment is

operated from the same line. The

chart gives minimum recommended

wire sizes for compressor

installations.

Recommended wire sizes may be larger

than the minimum set up by local

ordinances. If so, the larger size wire

should be used to prevent excessive

line voltage drop. The additional wire

cost is very small compared with the

cost of repairing or replacing a motor

electrically “starved” by the use of

supply wires which are too small.

GROUNDING

Improperly grounded

electrical components

are shock hazards.

Make sure all the components

are properly grounded to prevent

death or serious injury.

This product must be grounded.

Grounding reduces the risk of electrical

shock by providing an escape wire

for the electric current if short circuit

occurs. This product must be installed

and operated with a power cord or

cable that has a grounding wire.

MOTOR HOOKUP AND STARTER

INSTALLATION

Branch circuit protection must be

provided as specified in the United

States National Electrical Code, Chapter

2, “Wiring Design and Protection.”

Article 210, using the applicable article

“For Motors and Motor Controllers,”

(Article 430, Table 430-1 52).

IMPORTANT: Overload protection

is required for all motors. Certain

motors have this protection built-in.

To determine if a motor has built-in

overload protection, refer to the frame

size on the motor nameplate.

Motors with frame size R56HZ, Y56Y

or L143T include built-in overload

protection. No additional protection is

required. Use Figure 3 wiring diagram.

Motors with frame sizes 184T, 215T,

254T or 284T do not have built-in

overload protection. A magnetic

starter is required. Use Figure 4 wiring

diagram.

To change to the alternate voltage

on three phase motors with 230/460

ratings:

1. Rewire motor per data plate on

motor or instruction sheet.

2. Check electric rating of magnetic

starter and replace thermal

overload elements or magnetic

starter as required. The voltage and

amperage ratings are listed on the

motor nameplate.

DIRECTION OF ROTATION

NOTE: Improper rotation will result in

reduced unit life.

The direction of rotation must be

counterclockwise (as shown by the

arrow on the flywheel) while facing

the flywheel side of the pump. The

motor nameplate will show wiring

information for counterclockwise

rotation.

The proper direction is very

important. The direction of rotation

of 3 phase motors can be reversed

by interchanging any two motor-line

leads. For single phase motors, refer to

the motor nameplate.

Operating Instructions

4

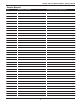

Chart 2: Minimum Wire Size

Use 75°C Copper Wire

Single

Phase

Three

Phase

HP

Amps

230 V

208 /

230 V

460 /

575 V

SPL

Up to 22.0

10

AWG

5.0

8

AWG

12

AWG

14

AWG

7.5

8

AWG

10

AWG

12

AWG

10.0

8

AWG

12

AWG

15.0

6

AWG

10

AWG

25.0

3

AWG

8

AWG

Isolation Pad

(available separately)

Tank

Tank Shut-Off Valve

(available separately)

Factory Mounted

Magnetic Starter

(not on all units)

Pump

Discharge

Tube

Motor

Safety Valve

Access

Figure 2 - Horizontal Unit Identification

Drain Valve

Discharge Port

Pressure Switch

Pressure

Gauge

Check

Valve