Operator`s manual

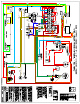

9” CHIPPER SERVICE

FEED WHEEL MOTOR

90

WARNING:

RELEASE HYDRAULIC PRESSURE BEFORE PERFORMING ANY SERVICE

TO HYDRAULIC LINES OR OTHER COMPONENTS.

FLUID UNDER PRESSURE CAN PENETRATE THE SKIN AND CAUSE

SEVERE INJURY. SEEK IMMEDIATE MEDICAL ATTENTION IF SKIN IS

PENETRATED. CHECK HOSES AND FITTINGS USING A BOARD OR

CARDBOARD; DO NOT USE HAND OR FINGER. ALWAYS WEAR EYE

PROTECTION.

Before changing feed wheel motor, release

the hydraulic pressure. Mark the location of

each hose, possibly with an R and L for right

and left hoses. Then disconnect the

hydraulic hoses and cap the ends of hoses

and the connections on the motor.

Remove the rubber guard that covers the

feed wheel coupling and bushing by

removing the two 3/8” bolts. Be sure to

keep all parts and hardware together to make

reassembly easier.

Remove the three bolts (3/8”) from the

bushing and screw these bolts back into the

three threaded holes in the bushing to push

the motor assembly off the bushing. Screw

these bolts in a little at a time to take the

assembly off without applying more

pressure to one side than the other.