Operator`s manual

9” CHIPPER SERVICE

FEED WHEEL MOTOR

91

When the motor assembly is off the

machine, move it to a workbench for easier

access. Then, remove the 1” nut that is

inside the coupling. You may need to use a

vise to hold the motor steady while you

break the nut loose since it was put on with

LocTite® 262 and then tightened to 150 ft.

lbs. CAUTION: Always wear eye

protection when working on hydraulic

components.

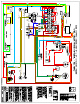

There is a special tool required to

separate the motor and coupling once it is

off the machine, contact J. P. Carlton or

your local dealer to purchase the puller.

Attach the separating tool to the coupler as

shown and screw the three bolts from the

bushing into the tool in the outside holes.

Screw the bolts into the coupling as far as

they will go. Now turn the bolt in the center

of the tool to pull the coupling off the feed

wheel motor.

Remove the torque arm held on with two

1/2” bolts. (The torque arm looks slightly

different on the lower feed motor, but is still

held on with two bolts.)