Installation guide

Table 1--Physical Data--Unit 50JZ

UNIT SIZE

NOMINAL CAPACITY (ton)

OPERATING WEIGHT (lb.)

COMPRESSOR QUANTITY

TYPE

REFRIGERANT

REFRIGERANT METERING DEVICE

Refrigerant (R-410A) Quantity (lb.)

ORIFICE ID (in.)

ORIFICE OD (in,)

OUTDOOR COIL

Rows.,. Fins/in.

face area (sq. ft.)

OUTDOOR FAN

Nominal Airflow (CFM)

Diameter

Motor HP (RPM)

INDOOR COIL

Rows._ Fins/in.

face area (sq. ft.)

INDOOR SLOWER

Nominal Airflow (CFM_

Size (in,)

Motor (HP)

HIGH-PRESSURE SWITCH (psig)

Cutout

Reset (Auto)

LOSS-OF-CHARGE/LOW-PRESSURE SWITCH

(Liquid Line) (psig)

Cutout

Reset (Auto)

RETURN-AIR FILTERS (in._"

throwaway

50JZ024 I 50JZ030 50JZ036 50JZ042 50JZ048 I 50JZ060

2 I 2-1/2 3 3-1/2 4 I 5299 320 328 350 355 428

1

SCROLL COMPRESSOR

R-410A

Accurater

7.0 8.9 9.3 9.5 10,6 12.4

0.061 0.061 0.067 0.073 0.076 0.088

0.032 (2) 0.040 (2) 0.040 (2) 0.038 (2) 0.046 (2) 0.052 (2)

2...17 2...17 2...17 2...J7 2..._7 2...17

8.5 10.3 10.3 13.5 13.5 15.4

2350 2350 2800 2500 3300 3300

22 22 22 22 22 22

1/8 (825) 1/8 (825) 1/4 (1100) 1/8 (825) 1/4 (1100) 1/4 (1100)

3...15 3...15 4...15 3...15 4...15 4,..15

3.7 3.7 3.7 4.7 4.7 / 5.7

800 1000 1200 1400 1600 / 1750

10x10 10x10 10x10 11x10 11x10 11x10

1/4 1/4 1/2 1/2 1/2 1

610 ± 15

420 ± 25

20± 5

45± 10

20x20x1f20x20Xli 20x2,xlf 24x30 1f 24x30Xlf 2,x30x1

• Required tilter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity of 300

if/minute for throwaway type or 450 if/minute for high-capacity type. Air tilter pressure drop for non-standard filters must not exceed 0.08 in. wg.

NOTE: These panels are held in place with tabs similar to an

electrical knockout.

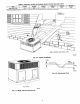

4. Reinstall the horizontal duct covers (Fig, 11) to block off the

horizontal air openings.

NOTE: Avoid abrupt duct size increases anti reductions. Abrupt

change in duct size adversely affects air performance.

r_ 'kk_r:_ttLllT[d

Step 6--Provide for Condensate Disposal

NOTE: Ensure that condensate-water disposal methods comply

with local codes, restrictions, and practices.

The 50JZ units dispose of condensate through a 3/4 in. NPT female

fitting that exits on the compressor end of the unit. Condensate

water can be drained directly onto the roof in rooftop installations

(where permitted) or onto a gravel apron in ground level installa-

tions, Install a field-supplied condensate trap at end of condensate

connection to ensure proper drainage. Make sure that the outlet of

the trap is at least I in. lower than the drain-pan condensate

connection to prevent the pan from overflowing. Prime the trap

with water. When using a gravel apron, make sure it slopes away

from the unit.

If the installation requires draining the condensate water away

from the unit, install a field-supplied 2 -in. trap at the condensate

connection to ensure proper drainage. Conden,_ate trap is available

as an accessory or is field supplied. Make sure that the outlet of the

trap is at least I in. lower than the unit drain-pan condensate

connection to prevent the pan from overflowing. Connect a drain

trough using a minimum of field-supplied 3/4 -in. PVC or

field-gupplJed 314 .in. copper pil)_ _ outh_l elt_ of _ 2 -in.

(See Fig. 12). Do not undersize the tube. Pitch the drain trough

downward at a slope of at least 1 in. every, 10 ft. of horizontal run.

Be sure to check the drain trough for leaks. Prime the trap at the

beginning of the cooling season start-up.

Step 7_nstall Electrical Connections

The unit cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of personal

injury if an electrical fault should occur. This ground may

consist of an electrical wire connected to the unit ground lug

in tile _ontrol compartment, or conduit approved for electrica_

ground when installed in accordance with NEC, ANSI/NFPA

American National Standards Institute/National Fire Protec-

tion Association (latest edition) iin Canada, Canadian Elec-

trical Code CSA C22.1) and local electrical codes. Failure to

adhere to this warning could result in serious injury or death.