Installation Sheet

Cavity Sliders USA Inc.

PO Box 1392

Culver City

CA 90232

T (888) 466 0030

F (310) 769 5824

E info@cavilock.com

www.cavitysliders.com

High quality

New Zealand made

products

When preparing track for top coat, CS recommends the use of Rust-Oleum® Self Etching Primer. This has been tested

on our product in our warehouse and is readily available nationwide. Other self etching primers may be used but we

recommended that you test first. Use the appropriate color primer for the top coat color you intend to use.

Preparing Track for Top Coat

Self Etching Primer - Technical Data Sheet

The technical data and suggestions for use contained herein are

correct to the best of our knowledge, and offered in good faith.

The statements of this literature do not constitute a warranty,

express, or implied, as to the performance of these products.

All technical information is subject to change without notice.

DESCRIPTION AND USES

Rust-Oleum® Self Etching Primer is designed to prepare

bare metal, aluminum and fiberglass surfaces to promote

maximum adhesion and smoothness of the topcoat

finish. Self Etching Primer is a rust preventive coating

that etches and primes in one coat. Self Etching Primer

features an advanced spray system that allows you to

spray at any angle, even upside down for those hard to

reach areas. A comfort spray tip with a wider finger pad

reduces fatigue caused by continuous spraying.

PRODUCT APPLICATION

PAINTING CONDITIONS - Use outdoors or in a well

ventilated area such as an open garage. Use when

temperature is between 50-90°F (10- 32°C) and humidity

is below 85% to ensure proper drying. Do not apply

to surfaces that, when heated, exceed 200°F (93°C) or

galvanized metal. Avoid spraying in very windy and

dusty conditions. Cover surrounding area to protect

from spray mist.

SURFACE PREPARATION - Thoroughly clean the area to

be primed with mineral spirits to remove all oil, grease,

wax and dirt. Allow the surface to dry thoroughly.

Lightly sand the surface with #400 grit wet or dry

sandpaper. Keep the sandpaper wet by soaking it in

water while sanding. Wipe the sanded surface clean

when finished.

APPLICATION - Shake can vigorously for one minute

after the mixing ball begins to rattle. If mixing ball fails

to rattle DO NOT STRIKE CAN. Contact Rust-Oleum.

Shake often during use. Hold can 12-16” from surface

and spray in a steady back-and-forth motion, slightly

overlapping each stroke. Keep the can the same

distance from the surface and in motion while spraying.

For best adhesion, apply 2 or 3 thin coats and allow

each coat to dry for 2 minutes before applying the next

coat. Allow the final coat of Self Etching Primer to dry

for a minimum of 3-4 hours before dry sanding, or 15

minutes before wet sanding with #400 grit sandpaper.

Do not use near open flame.

DRY & RECOAT - Dry and recoat times are based on

70°F (21°C) and 50% relative humidity. Allow more time

at cooler temperatures. Dries to the touch in 10 minutes

and to handle in 15-30 minutes. Apply a top coat after

30 minutes.

CLEAN-UP - Wipe off tip when finished. Clean up wet

paint with xylene or mineral spirits. Properly discard

empty container. Do not burn or place in home trash

compactor.

CLOGGING - If the valve clogs, twist and pull off spray

tip and rinse in a solvent such as mineral spirits. Do not

insert any object into can valve opening.

PHYSICAL PROPERTIES

SELF ETCHING PRIMER

Resin Type Modified Alkyd

Pigment Type Titanium Dioxide and

Inorganic Pigments

Solvents Acetone and Aromatic

Hydrocarbons

MIR 1.20 Max

Fill Weight 12 ounces

Recommended Dry Film

Thickness (DFT) Per Coat

1.5-2.5 mils (37.5-62.5µ)

Practical Coverage at

Recommended DFT

10-12 sq. ft./can

(0.90-1.09 m2/can)

Dry Times at 70°F

(21°C) and 50%

Relative Humidity

Touch 10 minutes

Handle 15-30 minutes

Topcoat After 30 minutes

Dry Heat Resistance 200°F (93°C)

Shelf Life 5 years

Flash Point -156°F (-104°C)

Safety Information For additional information,

see MSDS

61093 07.2015

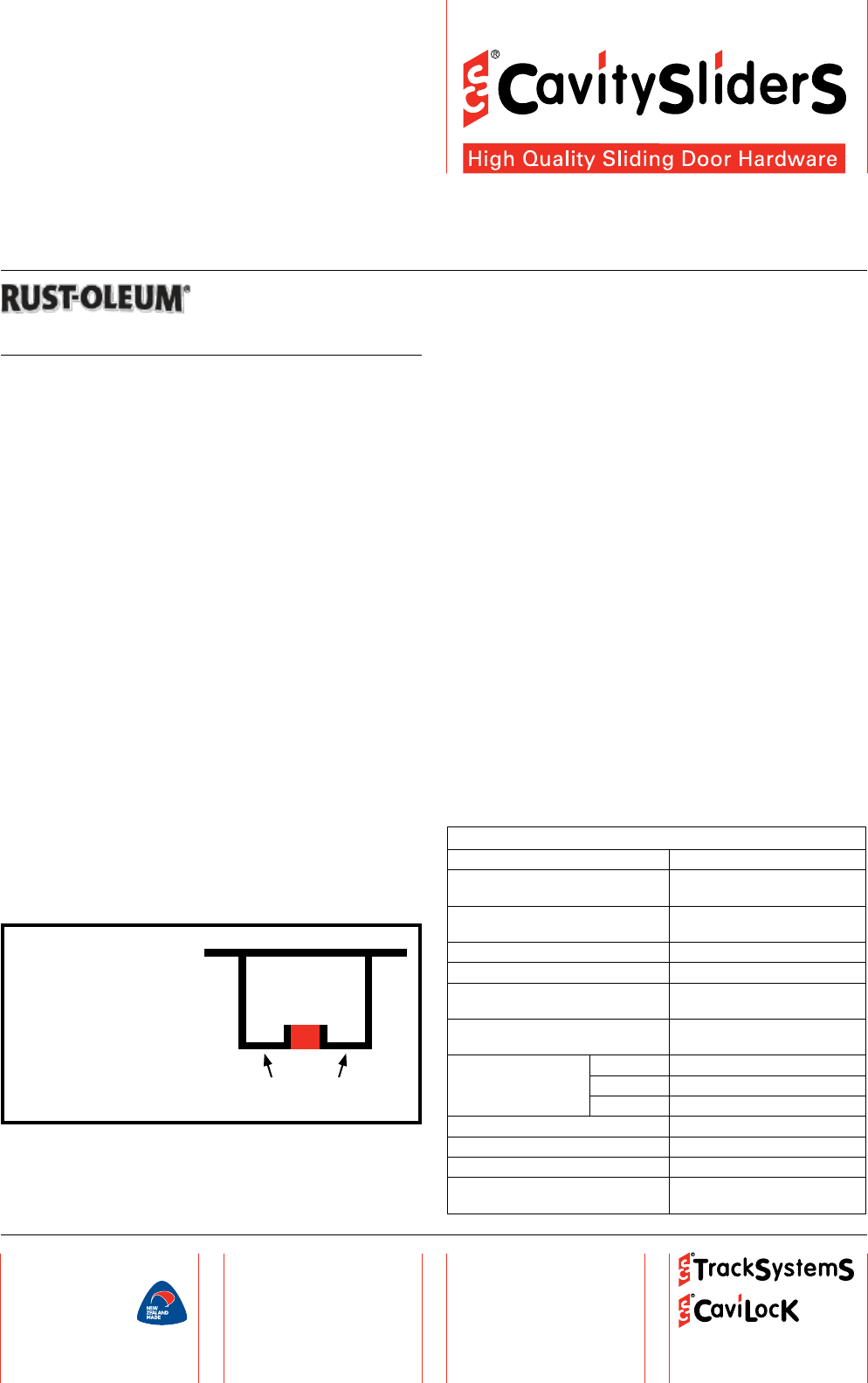

IMPORTANT!

Extra care must be taken

when sanding and painting

the track face.

Cover the gap highlighted

red along the whole length

of the track so NO dust or

paint overspray goes inside

the track.

Track face

NO DUST

OR PAINT