Service manual

Table Of Contents

- SOUND MIG 2035/M Pulse

- POWER SOURCE art. 285

- filo

- filo

- Gas

- Torch

- Art. 1242

- Torch

- filo

- Gas

- Torch

- Art. 1242

- Torch

- - Set-up mode diagram.

- - MAINTENANCE

- - Periodic inspection, cleaning.

- - Operating sequence.

- - Troubleshooting.

- - The power source does not start, control panel off.

- - Power source powered, control panel on, fan (24) stopped.

- - Power source powered, display and signals does not indicat

- - The start button produces no effect.

- - Power source powered, no gas flows from the torch.

- - Power source powered, the wire feeder motor does not work.

- - In open circuit operation, the output voltage is not regul

- - In resistive load operation, the output voltage is not reg

- - Arc difficult to strike, the arc goes out immediately afte

- - When start button is released, the wire sticks to the work

- - In synergic mode, the welding quality is not satisfactory,

- - Error codes and alarm signals.

- - 01 - Internal RAM error.

- - 02 - EEPROM error.

- - 10 - Malfunction in the circuit to detect short-circuits a

- - 14 - Microprocessor supply voltage error on control board

- - 20 - Absence of interlock signal on power board (26).

- - 25 - Malfunction on the EPLD bus in the control board (27)

- - 30 - Incorrect setting of the minimum current threshold on

- - 42 - Error in the signal of the motor encoder (401).

- - 52 - Start button pressed during start-up.

- - 53 - Start button pressed while resetting from stop due to

- - 54 - Short-circuit between torch and workpiece upon start-

- - 56 - Short-circuit at the output lasts too long (max. allo

- - 60 - Current too high beyond the maximum allowable limits

- - 73 - Display (G) indicates OPn = diode group (56) high tem

- - 80 - Display (G) indicates OPn = wire coil cover open.

- - 74 - Display (G) indicates tH = igbt high temperature.

- - 99 - Display (G) shows OFF = incorrect mains voltage signa

- - COMPONENTS LIST

- - ELECTRICAL DIAGRAMS

- - Power source art. 285 : see file SCHE285.pdf enclosed at t

- - Waveforms.

- - Filter board (47) code 5.602.164.

- - Power supply (25) board code 5.602.163.

- - Power board (26) code 5.602.162.

- - Driver-igbt board code 5.600.757.

- - Control board (27) code 5.602.157.

- - Panel board (41) code 5.602.178.

- - Push-pull board (43) code 5.602.171.

- - Snubber board (58) code 5.602.166.

- - Programming board (21) code 5.602.174.

- - MAINTENANCE

- - Set-up mode diagram.

CEBORA S.p.A. 41

5.10 - Snubber board (58) code 5.602.166.

5.10.1 - Topographical drawing.

5.10.2

- Connector table.

Conn. Terminals Function.

J1 1 - 2 wire coil cover open signal input.

J3 1 - 2 wire coil cover open or diode group (56) overtemperature signals output.

J4 1 - 2 diode group (56) overtemperature signal input.

- TP1 - TP5 transformer (30) secondary circuit end terminal input.

- TP6 - TP10 transformer (30) secondary circuit end terminal input.

- TP2 - TP7 diode group (56) cathode terminals output.

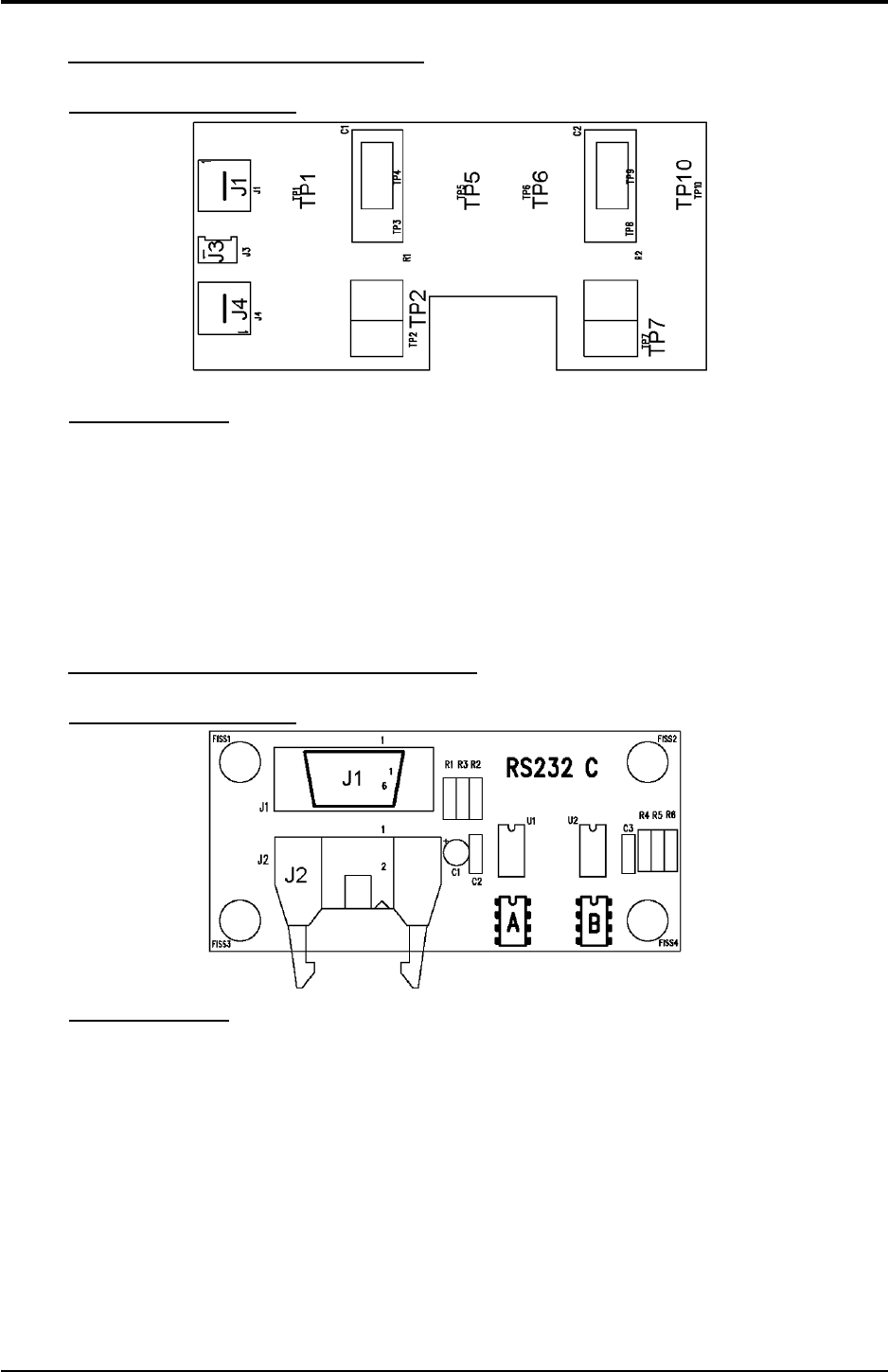

5.11 - Programming board (21) code 5.602.174.

5.11.1 - Topographical drawing.

5.11.2

- Connector table.

Conn. Terminals Function.

J1 2 Tx signal of serial communication line to outside (programming system).

J1 3 Rx signal of serial communication line to outside (programming system).

J1 5 GND for serial communication line signals (programming system).

J1 4 - 6 DTR/DSR signal of serial communication line to outside (programming system).

J1 7 - 8 RTS/CTS signal of serial communication line to outside (programming system)

J2 1(+) - 9(-) +5 Vdc input for programming board (21) and serial communication line to outside power

supply.

J2 3 Tx signal for serial communication line.

J2 5 Rx signal for serial communication line.

J2 7 SDA signal for programming board (21).

J2 8 SCL signal for programming board (21).

J2 10 WP signal for programming board (21).

U1 - connector for custom programs EEPROM.

U2 - connector for custom programs EEPROM.

3.302.161 24/03/2004