User manual

CompAir BroomWade Limited

page 14

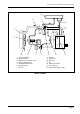

5. AIR/OIL SYSTEM

5.1 Description

The air/oil system comprises an air intake filter,

suction regulator, air-end, oil separator vessel, oil

separator filter, minimum pressure/non-return

valve, aftercooler, oil cooler with thermostatic

bypass valve and an oil filter. The flow of oil

through the circuit is achieved through the pressure

differential existing between the primary oil

separator and the oil injection point in the air-end.

5.2 Operation

Air enters the compressor unit through the intake

filter (2) and open suction regulator (1) to the inlet

port of the air-end (7). The air is trapped by the

turning rotors and mixes with the oil which enters

the casing through the oil injection point.

Continued rotor rotation increases the pressure and

temperature of the air/oil mixture which passes

from the air-end discharge pipe into the oil

separator (4) where primary separation takes place

by centrifugal force. Most of the oil is separated at

this stage and drops to the bottom of the vessel.

The remaining air/oil mixture then passes through

an oil separation element (5) where final separation

takes place. The separated oil collects in the

bottom of the filter and is scavenged back into the

air-end through a small diameter pipe.

The filtered air then passes from the oil separator

filter by way of the minimum pressure/ non-return

valve (3). Provided the air pressure at this stage is

above 3.5 to 4·0 bar the air passes through the

aftercooler (9) where it is cooled before passing to

the delivery outlet.

If the air pressure in the primary separator vessel

falls below 3.5 to 4·0 bar the minimum pressure

valve will close. The valve also incorporates a non-

return valve which operates to prevent delivery air

passing back into the separator when the

compressor is running off-load.

Oil from the bottom of the separator flows under

pressure to the oil cooler (10) and during normal

running the oil passes through the cooler to

maintain the correct temperature. A thermostatic

bypass valve (14) is installed in the inlet manifold of

the oil cooler.

When the compressor is started, the cold oil in the

system bypasses the cooler and flows through the

oil filter (8) directly to the air-end. As the oil and air

mixture is compressed by the rotors in the air-end,

the temperature of the oil increases.

When the oil has reached its normal operating

temperature the bypass valve closes and the oil is

directed through the oil cooler. The cooled oil then

flows to the oil filter where it is cleaned before

entering the air-end.

The quantity of oil injected into the air-end is

controlled by a restrictor orifice in the air-end

casing. Oil is injected under pressure through the

restrictor orifice into the rotors and a gallery

supplies oil to the air-end bearings.