User manual

CompAir BroomWade Limited

page 16

6. REGULATION SYSTEM

6.1 Description

The compressor is regulated through a combination

of electronic, pneumatic, electrical and mechanical

devices. Two modes of regulation are used: ‘On/

Off’ is fitted as standard, and ‘Modulating’ as an

optional extra.

6.2 On/Off Control

In the ‘On/Off’ mode, the compressor is regulated

by the pressure transmitter, which continuously

monitors the pressure in the user’s pipework, a run-

on time sequence within the controller and an

unloader solenoid valve.

The compressor operates in response to varying air

demand in either the on-load condition with the

suction regulator inlet valve fully open, or off-load

with the inlet valve fully closed.

When the controller switches the compressor to run

off-load, a run-on time sequence is activated. This

allows the compressor to run for a pre-set

(adjustable) period of time in the off-load condition.

If this time elapses before the pressure in the

user’s pipework has fallen to the lower set point,

the compressor stops and enters the ‘Standby’

condition.

The compressor will remain in the ‘Standby’

condition until the pressure transmitter senses that

the pressure in the user’s pipework has fallen to the

lower set point. The controller will then re-start the

compressor.

If the pressure in the user’s pipework falls to the

lower set point before the run on time has elapsed,

the controller will re-initialise the time sequence

and switch the compressor to run on-load.

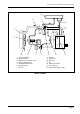

8. Separator Filter

9. Pressure Relief Valve

10. Separator Vessel

11. Air-end

12. Drive Motor

13. Intake Pressure Switch

14. Air-end Discharge Temperature Sensor

1. Air Intake Filter

2. Suction Regulator

3. Venting Valve

4. Unloader Solenoid Valve

5. Minimum Pressure/Non-return Valve

6. Pressure Transmitter

7. Aftercooler

M

+-

14

1

13

11 10

9

8

5

7

6

4

3

2

12

REGULATION SYSTEM – ON/OFF CONTROL