Owner`s manual

CHUCKKEY... It is a self-ejecting chuck key which

will "pop" out of the chuck when you let go of it. This

action is designed to help prevent throwing of the chuck

key from the chuck when power is turned "ON". Do not

use any other key as a substitute, order a new one if

damaged or lost.

DRiLLiNG SPEED... Can be changed by placing the

belt in any of the STEPS (grooves) in the pulleys. See

Spindle Speed chart on right side of Head.

To determine the approximate drilling speed, refer to

the table on the LEFT side of the drill press head.

BELT TENSION... Refer to section "Assembly - Instal-

ling and Tensioning Belt" (Page 9).

3/16" ROD

CHUCK KEY

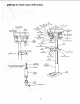

REMOVING THE CHUCK

1. Insert a piece of 1/4" dia. steel rod in one of the

holes in the chuck body.

2. Insert 3/16" alia. rod or drill into one of the holes in

the collar.., turn it in the direction of arrow until

LOOSE. Continue to turn it until the chuck is re-

leased.

J

CHUCK

BODY

LOCKING

COLLAR

1/4" ROD /

OR DRILL \ •

CHUCK

SLEEVE

DRILLING TO DEPTH

To drill a BLIND hole (not all the way through) to a

given depth, can be done two ways.

1. Mark the depth of the hole on the side of the work-

piece.

2. With the switch OFF bring the drill down until the

TIP or lips are even with the Mark.

3. Spin the lower nut down to contact the depth stop

lug on the Head.

4. Move the POINTER all the way down.

5. Spin the upper nut down and tighten against the

pointer.

ANOTHER WAY -- DEPTH SCALE

1. With the switch OFF, bring the drill down until the

TIP touches the TOP of the WORKPIECE.

2. Adjust the nuts so the Pointer is set to the desired

DEPTH... TIGHTEN the UPPER NUT against the

Pointer. For example.., if you want to drill a hole

one inch deep, set the pointer at the one inch mark

in the scale.

--J !/_ SCALE

• _ 19 T UPPER

_"[ _____ J STOP NUT

TIP TOUCHES _ _1_ "STOP NUT

WORKPIECE__L_""

17