Installation Guide

48

STEP 3: Constructing the Bending Rail

The inside of the bending mold should be covered with

wax paper or plastic to prevent the glue from sticking to

the mold.

Special care must be taken if the required rail length is

longer than 16'. Shorter rails have to be spliced together to

provide these lengths. A butt joint on each layer of rail is

used to make this splice. These butt joints must be

staggered about 30" to maintain strength throughout the

splice and to minimize the bulge in the rail. Each butt joint

should have a 10" strip of nylon tape to hold the pieces

together while bending the rail (see Fig. Al-3).

Apply a thin even coat of carpenter’s glue to all contact

surfaces of the rail; a finishing sponge or tape roller would

be helpful. The rail should be assembled one layer at a

time, gluing each piece completely, starting from one

bending mold section and finishing with the other bending

mold section. Once assembled, use nylon tape to wrap the

rail about every 3'. This provides support while the rail is

being bent.

Clamp the rail at one end. Form the rail to the curve by

carefully pulling the rail to the guides and clamping it. At

each bending guide, clamp the rail to the vertical brace,

keeping the rail down on the front edge of the guide.

Continue one guide at a time to the end of the rail. A

clamp should be placed on each guide and between the

guides, no more than 6" apart (see Fig. Al-4). Clamp the rail

as of

ten as possible to provide a smooth bend in the rail

and good glue adhesion.

Stagger butt

joints for strength

U

se nylon tape to

secure butt joints

B ENDING R AIL

I NSTALLATION

APPENDIX 1

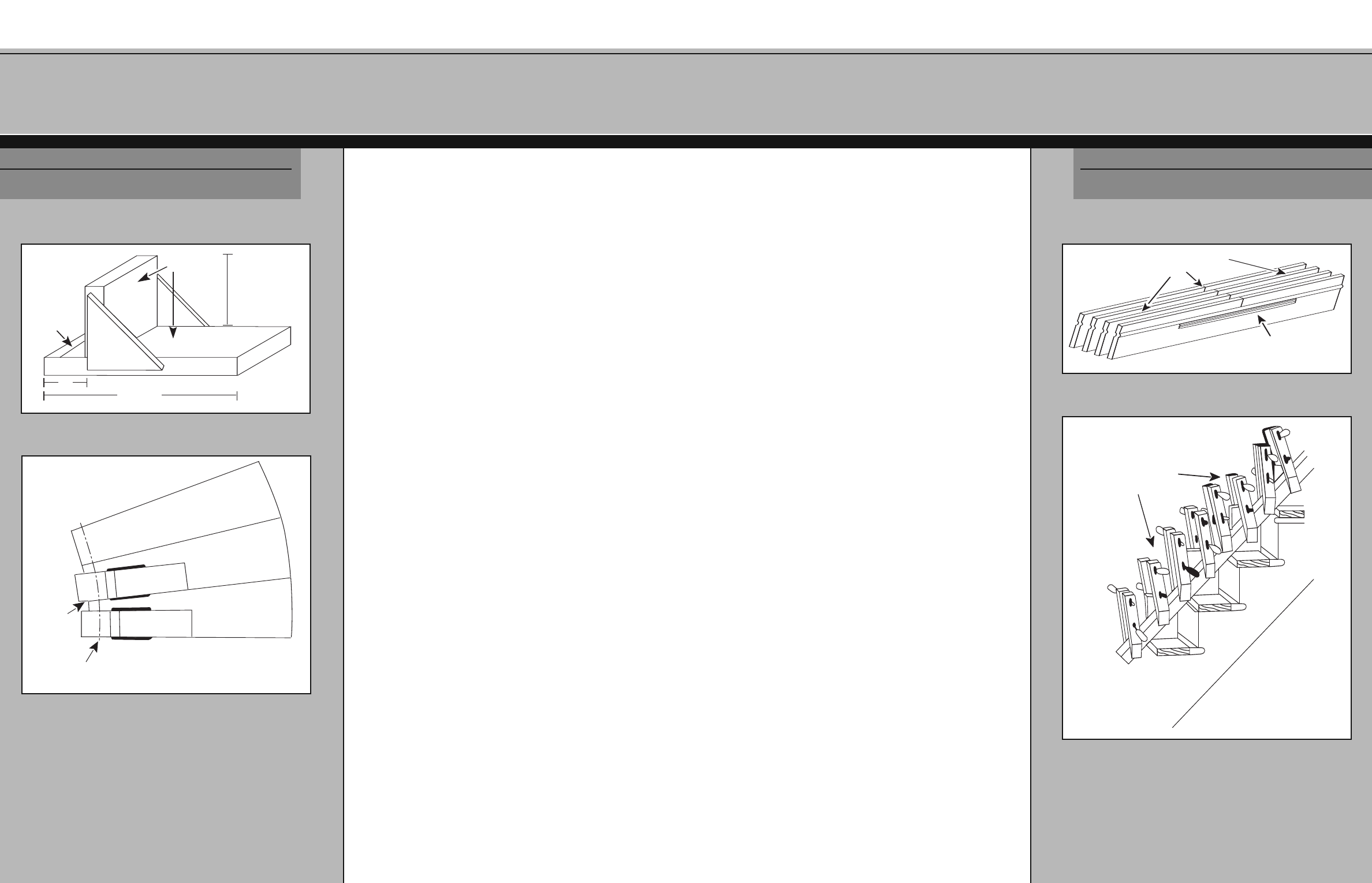

FIG. A1-3 - Splicing bending rail

4

7

Read all instructions carefully before starting.

The following procedures provide guidance for assembling

curved balustrades and balcony handrails.

STEP 1: Important Considerations Prior to Starting

The run, rise and radius of the staircase where the curved

rail is to be installed must be constant. For successful

results, the radius of the stairway should not be less than

the following:

STAIRCASES

6010B (30") 6210B (30") 6519B (36" to 42")

LEVEL BALCONY HANDRAIL

6010B (36") 6210B (42") 6519B (36" to 42")

STEP 2: Bending Guides

Build the bending guides as in Fig. A1-1. You will need a

bending guide for each tread. Find the centerline of the rail

b

y measur

ing t

he t

otal width of the rail, including the

bending mold, and dividing this width in half. Mark the

centerline on each bending guide, measuring from the

v

ertical brace. To protect the treads from glue, cover them

with a clear plastic.

N

ow, clamp the guides to the treads, keeping the rail

centerline aligned with the baluster centerline. The leading

edge of the bending guide must be flush with the tread

nosing. F

ig. Al-2 shows proper placement of the

bending guides.

The same basic procedure is used for a curved balcony.

Mark

t

he rail

centerline

2" x 6"

6"

6"

18-20"

APPENDIX 1

B ENDING R AIL

I NSTALLATION

FIG. A1-1 - Bending rail guides

Align rail centerline with

baluster centerline

Clamp in place,

flush with

tread nosing

FIG. A1-2 - Placement of bending rail guides

Place a clamp on each guide and no

more than 6" apart in between guides

FIG. A1-4 - Clamping the bending rail