Installation Guide

8

STEP A.6 – Dry Fit the Starting Step

See Step B.2 and StairNote Five: All About Starting Steps

NOTE: If no starting step is to be used (first tread same as

all o

thers), go to Step A.7.

Begin by dry fitting the starting step riser (leave the tread

off). Rip it to the height of the first riser on the stringers.

Always rip the bottom edge of the riser. A table saw will

provide the smoothest and easiest cut. Slide the starting

step riser along the saw blade and carefully roll the riser up

to complete the trimming on the bullnose end (see Fig. 6-

1). Any irregularities in the cut will be hidden later by the

finish flooring or by shoe molding.

Determine the dimension of the first rise and rip the

starting riser

1

/1

6

" less. Place the riser end against the wall

skirt board and measure the gap between the curved end

and the mitered skirt board. Subtract

1

/2" from this

dimension and trim that much off the straight end. Slide

the riser back in place, but put a

3

/4" piece of scrap between

t

he curv

ed end and the skirt board. Scribe a line on the

straight end, using a

3

/4" block (see Fig. 6-2). Trim to this

scribe line and check for a snug fit.

The tread is cut to length in a similar manner. Place the

tread on the riser and butt the straight end against the wall

skir

t boar

d. Measur

e the gap between the notch and the

mitered skirt board on the curved end. Subtract

1

/2" from

this dimension and trim that much off the straight end.

Slide t

he tr

ead back in place, but put a

3

/4" piece of scr

ap

between the notch and the mitered skirt board. Scribe a

line on the straight end, using a

3

/4" block. Trim and check

f

or a snug f

it.

Wall

Skirtboard

3

/

4

" Scribe Block

Stringer

3

/

4

" Block

S TEP

A.6

SECTION A

7

If the stairway is closed on both sides, the task of scribing

both ends must be done on scraps and transferred to the

actual risers. Rip all risers and scraps as described above.

Cut all scraps

1

/2" shorter than the smallest inside

dimension. Place a scrap riser across the stringers, butt one

end against the skirt board, and scribe a line. Now do the

same at the other end. Trim both ends to the scribe lines.

Now place the scrap back on the stringers and butt either

end tightly to the skirt board. Precisely measure the distance

from the other end of the riser to the skirt board. Lay the

scrap on the actual riser blank and transfer one scribe line

to the riser. Slide the scrap toward the other end the exact

distance that was measured above. Scribe and trim the other

end. Use a 3˚ bevel to make this cut and it will be easier to

swing this end into place.

1

2 3

SECTION A

S TEP

A.5

Starting steps add character and

distinction to a stairway. The

g

entl

y rounded r

iser of a

starting step relieves the “boxy”

look of a plain s

tairway. In over-

t

he-pos

t inst

allations t

he

projecting “bullnose” ends

permit the placement of newels

of

f t

he cent

er

line. This allows

the use of a handrail that starts

with a decorative curved volute

or tur

nout.

Bullnose starting steps increase the overall width of a staircase by

appr

o

ximat

el

y 10" to 11

1

/4". An e

x

cep

tion t

o this is the “quarter

cir

cle” design t

hat is int

ended f

or use in ins

t

allations wher

e the

first newel is usually at the second riser. Verify this installation will

compl

y with local building code. Additionally, quarter circle starting

steps work well with post-to-post installations (see Fig. S-5b).

S

tudy t

he selection of

starting steps, treads,

and riser

s in the

cat

alog for a bett

er

understanding of this

beautiful f

eatur

e of

t

he Cr

o

wn Her

it

ag

e

Stairway System.

W

A

L

L

Landing

Newel

position

Quarter circle

(2 ends)

starting step

Newel

position

Quarter circle

starting step

W

A

L

L

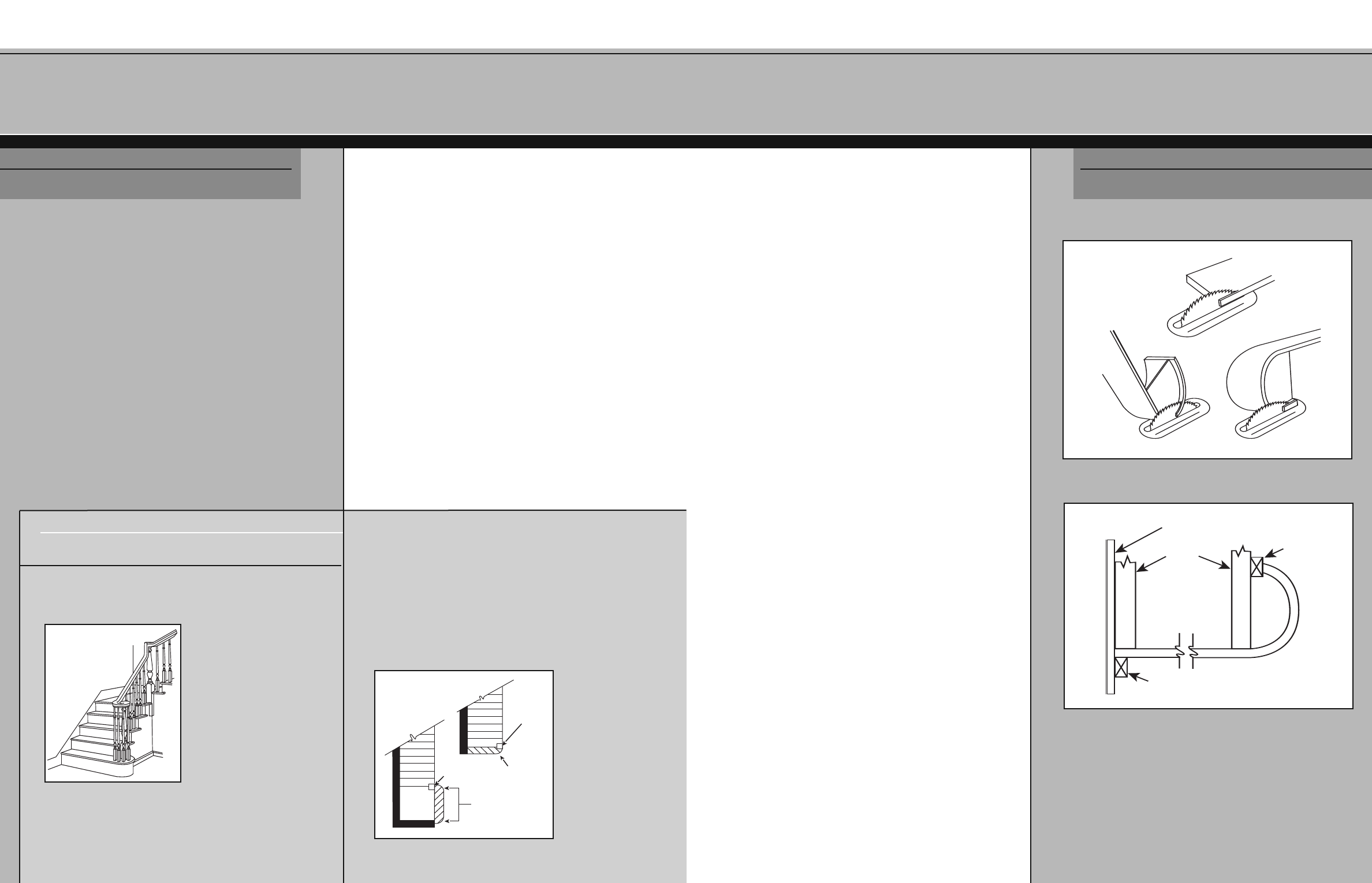

FIG. 6-1 - Cutting a starting step riser

FIG. 6-2 - Scribing using a scribe block

FIG. S-5a - Starting steps add

character and distinction

FIG. S-5b - Quarter circle starting steps also

can be used in post-to-post installations

S TAIRN OTE

F IVE

A LL A B OUT

S TARTING S TEPS