Quick Specs

Designed for high-volume frying and

controlled performance

High-production cooking capacity and fast recovery meet high-

volume frying needs. Oil capacities of these units make them

ideal for everything from French fries to large-size menu items

requiring more frying area.

A larger heat-transfer area reduces the heat per square inch

needed to attain and maintain desired cooking temperatures,

which reduces the oil’s heat load and therefore the breakdown

of the oil. Stainless steel baffles and reliable, built-to-last burners

keep maintenance to a minimum. Precise temperature control

during heat-up and recovery protects oil from excessive high-

heat damage. The wide cold zone traps sediment away from the

cooking area, safeguarding oil quality and the quality of the food.

High-production cooking capacity and fast recovery meet high-

volume frying needs.

Dean’s renowned, built-in filtration system puts filtration where

it’s most convenient to use -- right within the fryer battery --

eliminating the need for additional floor and storage space.

The filtering process is fast and easy, encouraging frequent

filtering -- a critical part of maximizing oil life, especially with

trans-fat free oils. It is also sequential, so one fryer may be filtered

while the others are still in use. It is engineered with features that

allow added convenience and ease of use.

This system is enhanced with a gravity draining system that

allows residual oil to drain into the filter pan so that drain lines

are always open. The filter, housed beneath two Dean fryers or

one fryer and a spreader, is capable of filtering up to six fryers,

individually, without having to be moved from fryer to fryer,

saving valuable labor. Oil can be filtered quickly while other fryers

in the battery continue cooking.

This filter comes standard with a powerful 4 GPM pump to

maximize filtering efficiency and minimize clogging. Large sump

with secure hold-down ring ensures proper vacuum and superior

oil filtration. The stainless steel filter pan is equipped with casters

and an automatic connection for ease of access.

Filtration process is two steps:

Step one: open drain valve, open return valve to activate filter

pump.

Step two: close drain valve; close return valve to turn off pump.

Specifications

Fryer Standard Features

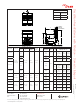

SCFD250G

SCFD350G

SCFD450G

SCFD550G

SCFD650G

SCFD260G

SCFD360G

SCFD460G

SCFD280G

SCFD380G

SCFD480G

Models

Decathlon Gas Fryer Batteries with

Filtration -- Domestic & Export

Decathlon Fryer Batteries with Filtration -- Domestic & Export

Project

Item

Quantity

CSI Section 11400

Approval

Date

• Thermo-tube design heat transfer system

• Oil capacity

SCFD50G -- 50-lb. (25 liter)

SCFD60G -- 75-lb (37 liter)

SCFD80G -- 100-lb. (50 liter)

• Btu/hr. input

SCFD50G -- 120,000 Btu/hr. (30,600 kcal) (35.2 kw)

SCFD60G -- 150,000 Btu/hr. (37,783 kcal) (44 kw)

SCFD80G -- 165,000 Btu/hr. (41,562 kcal) (48.3 kw)

• Frying area

SCFD50G -- 14” x 14” x 3-1/2” (35 x 35 x 8.9 cm)

SCFD60G -- 18” x 18” x 3-3/4” (46 x 46 x 9.5 cm)

SCFD80G -- 20” x 20” x 3-3/4” (51 x 51 x 9.5 cm)

• Thermatron controller

• Robust, RTD, 1° compensating temperature

probe

• Stainless-steel frypot, door, front and sides

• Two twin baskets

• Gas connection -- see chart on back

• Combination gas valve with regulator

• Wide cold zone

• Melt cycle and boil-out mode

• Casters

• Drain safety switch

8700 Line Avenue

Shreveport, LA 71106

USA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 830-0043

Revised 7/14/15

SCFD250G

Shown with optional CM3.5 controllers.

Filter Standard Features

• Space-saving filter fits inside fryer cabi-

net which houses two or more frypots or

one frypot and spreader

• Large capacity filter pan removes easily

for cleaning

• Sloped drain pan leaves minimal oil in

the pan after filtering

• Large 3” (8.0 cm) round drain line allows

oil to drain freely

• Filter cycle is complete from start to

finish in under 5 minutes, while other

frypots in the system are in use

• Filters all fryers in the battery

• Rear oil flush

• 1-1/4” (3.2 cm) diameter, one-point end

connection, rear manifold gas line with-

out shut-off valve

• 1/3 H.P. filter motor

• 4 GPM pump (15 LPM) pump

• Stainless steel crumb catcher

• Filter starter kit

• Casters