Installation Guide

Insert

Rail

Cap Rail

Angle adaptor wedges are available for 22.5˚ and 45˚ rail angles. Important: the holes in

the angle adaptor wedges line up with the stair rail connectors (sold separately).

If installing a 22.5˚ angle railing, attach the stair connectors and wedges centered

on the posts. If installing a 45˚ angle railing, attach the 45˚ adaptor wedges

centered on the posts. Attach stair connectors to the 45˚ using the provided

screws.

Measure the distance between the installed angle connectors to determine the length

of the top and bottom rails. Cut the top and bottom rails to length.

Step 7 Determine the spacing of the balusters.

Classic, Estate and balusters The rails are pre-drilled with the proper

spacing. Attach baluster connectors to the top and bottom rails. Do not over-tighten

screws. Apply silicone caulk on each connector to prevent balusters from turning or

rattling after installation is complete. The caulk should be on the outside of the round

connector, and on the inside of the designer baluster connectors.

NOTE: Use screws

(self tapping) that are included with rail kit for Classic, Estate and Twist Balusters. DO NOT

USE screw included with baluster connectors.

Ellipse balusters Both top and bottom rails will be installed with the pre-drilled

holes facing down to prevent water from collecting in the rail. 4-1/4" on-center and

equal spacing for the end spacing. Start by finding the center of the rail. Rail length

÷ 2 = center of rail. Mark every 4-1/4" from the center line to each end. This will

leave the end spacing 4" or less on both ends and require 3 Ellipse balusters per

foot. Attach connectors to both rails on marked locations.

s. NOTE: Use screws (self tap-

ping) that are included with rail kit for Classic, Estate and Twist Balusters. DO NOT USE screw

included with baluster connectors.

Traditional, Baroque and Arc balusters Both top and bottom rails will be

installed with the pre-drilled holes facing down to prevent water from collecting in

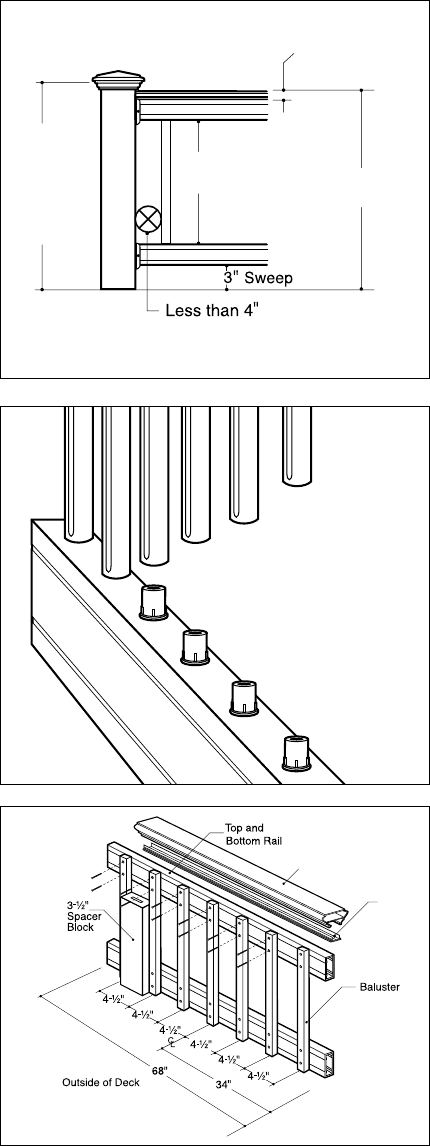

the rail. Maximum 4-1/2" on-center and equal spacing for the end spacing. Start

by finding the center of the rail. Rail length ÷ 2 = center of rail. Start the first aluminum

baluster on-center of the center line. Mark every 4-1/2" from this line to each end.

This will leave the end spacing less than 4" on both ends and require 2.5 aluminum

balusters per foot (fig. 4). Tip: Use a piece of 2x4 (3-1/2" actual) as a spacer block

for the spacing between balusters.

Glass balusters Both top and bottom rails will be installed with the pre-drilled holes

facing down to prevent water from collecting in the rail. 7-1/2" on-center and equal

spacing for the end spacing. Start by finding the center of the rail. Rail length ÷ 2 =

center of rail. Start the first glass baluster on-center of the center line. Mark every 7-1/2"

from the center line to each end. This will leave the end spacing 4" or less on both ends

and require 1.5 glass balusters per foot. If installing using connectors, attach connectors

to both rails on marked locations. Tip: If face-mounting to rail, use a piece of 2x4 (3-1/2"

actual) as a spacer block for the spacing between balusters (fig. 5).

Step 8 Position the bottom rail between posts and center. Note: Check building code

requirements for maximum spacing between deck surface and bottom of rail (sweep).

Spacing of 3" is recommended, but can be more or less if codes allow (fig. 3). Mark

the location of the bracket on both posts. Remove rail. Mark the screw locations and

pre-drill through the post sleeve only, using a 1/4" drill bit. Attach each bracket to the

post with two 2" screws.

Step 9 A support block is needed at the center of each rail. Cut the support block to

the proper height. Attach to the bottom of the lower rail (refer to fig. 1). Find the center

of the rail and pre-drill using a 1/8" drill bit. Attach the support block connector using the

included screw. Mark the location of the support block on the deck surface and attach the

other support block connector to the deck using the included screw. Install the bottom

rail between the posts. Using the brackets as a guide, pre-drill each screw hole using

a 1/8" drill bit and attach each end to brackets using two 1" screws. Tip: Use a driver

extension bit to avoid marring the rail or post sleeve with the drill chuck.

Step 10 Figure 3 illustrates how a 36"-high railing might be sized. Note: Use a fixture

to ensure a consistent length (+/- 1/16").

Classic, Estate and Glass balusters using

connectors Attach balusters to the lower rail by sliding onto connectors (fig. 4).

Step 11 Position the top rail between the posts. Check for level end-to-end and vertically.

Mark the bracket location on post sleeve and remove rail. Mark the screw locations using

the bracket as a guide, and pre-drill using a 1/4" drill bit through the post sleeve only. Attach

bracket to the post with two 2" screws at one end. Repeat for the other end.

Classic, Estate, balusters and Glass balusters using

connectors Lower the top rail into position, placing the balusters onto the connectors

while working from one end of the railing to the other. Tap with a rubber mallet if

needed to eliminate any gaps. Attach the rail to each bracket by pre-drilling with a

1/8" drill bit and using three 1" screws. Tip: Use a driver extension bit to avoid marring

the rail or post sleeve with the drill chuck.

37-

1

/2" Rail

Height

39"

Post

Sleeve

Height

(Rail

Height

plus 1-

1

/2")

26" Baluster

Height

1-

1

/

2

"

Cap Rail

fig. 3

fig. 4

fig. 5