Specifications

Table Of Contents

- Preface

- Table of Contents

- Chapter 1 Introduction

- Chapter 2 Installation and Wiring

- Chapter 3 Start Up

- Chapter 4 Digital Keypad Operation

- Chapter 5 Parameters

- 5.1 Summary of Parameter Settings

- Group 0 User Parameters

- Group 1 Basic Parameters

- Group 2 Operation Method Parameters

- Group 3 Output Function Parameters

- Group 4 Input Function Parameters

- Group 5 Multi-Step Speed and PLC Parameters

- Group 6 Protection Parameters

- Group 7 Motor Parameters

- Group 8 Special Parameters

- Group 9 Communication Parameters

- Group A PID Parameters

- 5.2 Parameter Settings for Applications

- 5.3 Description of Parameter Settings

- Group 0: User Parameters

- Group 1: Basic Parameters

- Group 2: Operation Method Parameters

- Group 3: Output Function Parameters

- Group 4: Input Function Parameters

- Group 5: Multi-step Speeds and PLC (Process Logic Control) Parameters

- Group 6: Protection Parameters

- Group 7: Motor Parameters

- Group 8: Special Parameters

- Group 9: Communication Parameters

- Group A: PID Control

- 5.1 Summary of Parameter Settings

- Chapter 6 Fault Code Information

- Chapter 7 Troubleshooting

- 7.1 Over Current (OC)

- 7.2 Ground Fault

- 7.3 Over Voltage (OV)

- 7.4 Low Voltage (Lv)

- 7.5 Over Heat (OH)

- 7.6 Overload

- 7.7 Keypad Display is Abnormal

- 7.8 Phase Loss (PHL)

- 7.9 Motor cannot Run

- 7.10 Motor Speed cannot be Changed

- 7.11 Motor Stalls during Acceleration

- 7.12 The Motor does not Run as Expected

- 7.13 Electromagnetic/Induction Noise

- 7.14 Environmental Condition

- 7.15 Affecting Other Machines

- Chapter 8 Maintenance and Inspections

- Appendix A Specifications

- Appendix B Accessories

- Appendix C How to Select the Right AC Motor Drive

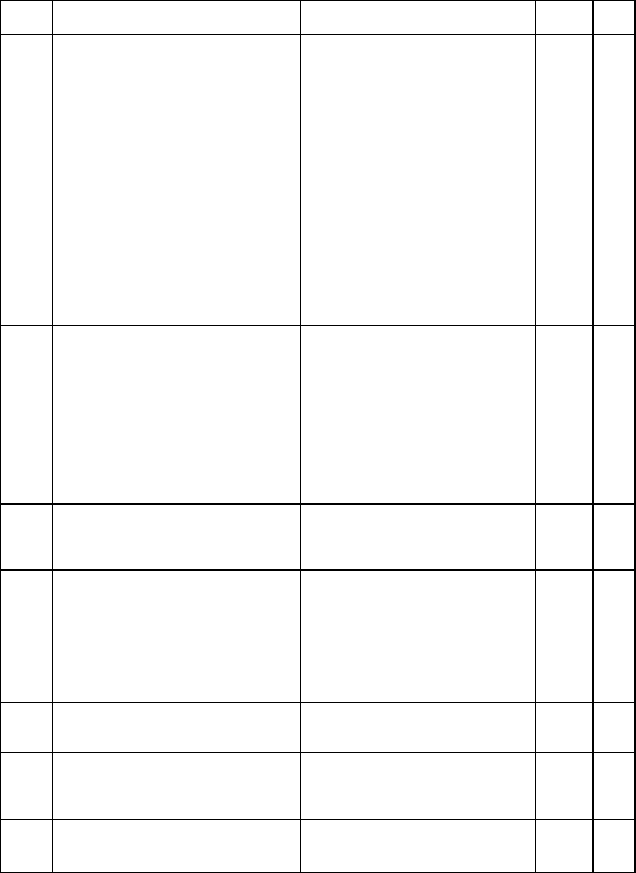

Chapter 5 Parameters|VFD-S Series

5-4 Revision August 2008, SE09, SW V2.61

Pr. Explanation Settings

Factory

Setting

NOTE

2-00

Source of Master Frequency

Command

d3: Master Frequency determined

by Potentiometer on the digital

keypad. (won’t record the

frequency of power loss and it

can do analog overlap plus)

d4: Master Frequency operated by

RS-485 serial communication

interface and record frequency

of power loss. (record the

frequency of power loss and it

can do analog overlap plus)

d5: Master Frequency operated by

RS-485 serial communication

interface and won’t record

frequency before power loss.

(won’t record the frequency of

power loss and it can do analog

overlap plus)

d0

2-01

Source of Operation

Command

d0: Digital Keypad

d1: External terminals. Keypad

STOP/RESET enabled.

d2: External terminals. Keypad

STOP/RESET disabled.

d3: RS-485 serial communication

(RJ-11) .Keypad STOP/RESET

enabled.

d4: RS-485 serial communication

(RJ-11). Keypad STOP/RESET

disabled.

d0

2-02 Stop Method

d0: STOP: ramp to stop; E.F.: coast

to stop

d1: STOP: coast to stop; E.F.: coast

to stop

d0

2-03 PWM Carrier Frequency Selections

d3: 3KHz

d4: 4KHz

d5: 5KHz

d6: 6KHz

d7: 7KHz

d8: 8KHz

d9: 9KHz

d10: 10KHz

d10

2-04 Motor Direction Control

d0: Enable forward/reverse

operation

d1: Disable reverse operation

d0

2-05 Loss of ACI Signal

d0: Decelerate to 0 Hz

d1: Coast to stop and display “EF”

d2: Continue operation by last

frequency command

d0

2-06 Analog Auxiliary Frequency Operation

d0: Disable

d1: Enable + AVI

d2: Enable + ACI

d0