Network Device Product Manual

Table Of Contents

- Preface

- Table of Contents

- Chapter 1 Introduction

- Chapter 2 Installation and Wiring

- Chapter 3 Start Up

- Chapter 4 Digital Keypad Operation

- Chapter 5 Parameters

- 5.1 Summary of Parameter Settings

- Group 0 User Parameters

- Group 1 Basic Parameters

- Group 2 Operation Method Parameters

- Group 3 Output Function Parameters

- Group 4 Input Function Parameters

- Group 5 Multi-Step Speed and PLC Parameters

- Group 6 Protection Parameters

- Group 7 Motor Parameters

- Group 8 Special Parameters

- Group 9 Communication Parameters

- Group A PID Parameters

- 5.2 Parameter Settings for Applications

- 5.3 Description of Parameter Settings

- Group 0: User Parameters

- Group 1: Basic Parameters

- Group 2: Operation Method Parameters

- Group 3: Output Function Parameters

- Group 4: Input Function Parameters

- Group 5: Multi-step Speeds and PLC (Process Logic Control) Parameters

- Group 6: Protection Parameters

- Group 7: Motor Parameters

- Group 8: Special Parameters

- Group 9: Communication Parameters

- Group A: PID Control

- 5.1 Summary of Parameter Settings

- Chapter 6 Fault Code Information

- Chapter 7 Troubleshooting

- 7.1 Over Current (OC)

- 7.2 Ground Fault

- 7.3 Over Voltage (OV)

- 7.4 Low Voltage (Lv)

- 7.5 Over Heat (OH)

- 7.6 Overload

- 7.7 Keypad Display is Abnormal

- 7.8 Phase Loss (PHL)

- 7.9 Motor cannot Run

- 7.10 Motor Speed cannot be Changed

- 7.11 Motor Stalls during Acceleration

- 7.12 The Motor does not Run as Expected

- 7.13 Electromagnetic/Induction Noise

- 7.14 Environmental Condition

- 7.15 Affecting Other Machines

- Chapter 8 Maintenance and Inspections

- Appendix A Specifications

- Appendix B Accessories

- Appendix C How to Select the Right AC Motor Drive

Chapter 8 Maintenance and Inspections|VFD-S Series

8-4 Revision August 2008, SE09, SW V2.61

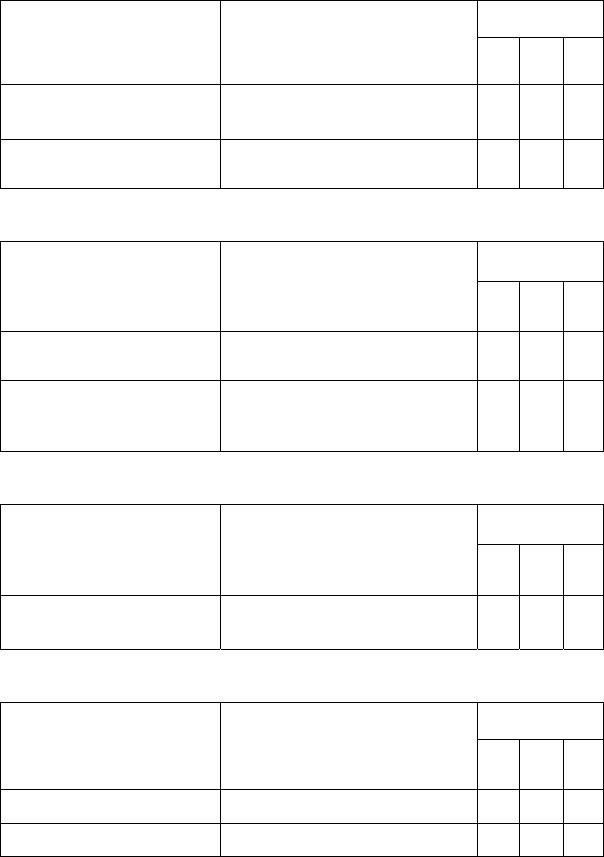

DC capacity of main circuit

Maintenance

Period

Check Items Methods and Criterion

Daily

Half

Year

One

Year

If there is any leakage of liquid,

change of color, cracks or

deformation

Visual inspection

{

Measure static capacity when

required

Static capacity

≥

initial value X 0.85

{

Resistor of main circuit

Maintenance

Period

Check Items Methods and Criterion

Daily

Half

Year

One

Year

If there is any peculiar smell or

insulator cracks due to

overheating

Visual inspection, smell

{

If there is any disconnection

Visual inspection or measure with

multimeter after removing wiring

between +1/+2 ~ -

Resistor value should be within

±

10%

{

Transformer and reactor of main circuit

Maintenance

Period

Check Items Methods and Criterion

Daily

Half

Year

One

Year

If there is any abnormal vibration

or peculiar smell

Visual, aural inspection and smell

{

Magnetic contactor and relay of main circuit

Maintenance

Period

Check Items Methods and Criterion

Daily

Half

Year

One

Year

If there are any loose screws

Visual and aural inspection. Tighten

screw if necessary.

{

Check to see if contacts work

correctly

Visual inspection

{