Network Device Product Manual

Table Of Contents

- Preface

- Table of Contents

- Chapter 1 Introduction

- Chapter 2 Installation and Wiring

- Chapter 3 Start Up

- Chapter 4 Digital Keypad Operation

- Chapter 5 Parameters

- 5.1 Summary of Parameter Settings

- Group 0 User Parameters

- Group 1 Basic Parameters

- Group 2 Operation Method Parameters

- Group 3 Output Function Parameters

- Group 4 Input Function Parameters

- Group 5 Multi-Step Speed and PLC Parameters

- Group 6 Protection Parameters

- Group 7 Motor Parameters

- Group 8 Special Parameters

- Group 9 Communication Parameters

- Group A PID Parameters

- 5.2 Parameter Settings for Applications

- 5.3 Description of Parameter Settings

- Group 0: User Parameters

- Group 1: Basic Parameters

- Group 2: Operation Method Parameters

- Group 3: Output Function Parameters

- Group 4: Input Function Parameters

- Group 5: Multi-step Speeds and PLC (Process Logic Control) Parameters

- Group 6: Protection Parameters

- Group 7: Motor Parameters

- Group 8: Special Parameters

- Group 9: Communication Parameters

- Group A: PID Control

- 5.1 Summary of Parameter Settings

- Chapter 6 Fault Code Information

- Chapter 7 Troubleshooting

- 7.1 Over Current (OC)

- 7.2 Ground Fault

- 7.3 Over Voltage (OV)

- 7.4 Low Voltage (Lv)

- 7.5 Over Heat (OH)

- 7.6 Overload

- 7.7 Keypad Display is Abnormal

- 7.8 Phase Loss (PHL)

- 7.9 Motor cannot Run

- 7.10 Motor Speed cannot be Changed

- 7.11 Motor Stalls during Acceleration

- 7.12 The Motor does not Run as Expected

- 7.13 Electromagnetic/Induction Noise

- 7.14 Environmental Condition

- 7.15 Affecting Other Machines

- Chapter 8 Maintenance and Inspections

- Appendix A Specifications

- Appendix B Accessories

- Appendix C How to Select the Right AC Motor Drive

Chapter 8Appendix C How to Select the Right AC Motor Drive

|VFD-S Series

Revision August 2008, SE09, SW V2.61 C-5

D. If the stall prevention function is activated, the accel./decel. time is automatically

extended to a length that the AC Motor Drive can handle. If the motor needs to

decelerate within a certain time with high load inertia that can’t be handled by the AC

Motor Drive in the required time, either use an external brake resistor and/or brake unit,

depending on the model, (to shorten deceleration time only) or increase the capacity for

both the motor and the AC Motor Drive.

C.3 How to Choose a Suitable Motor

Standard motor

When using the AC Motor Drive to control a standard 3-phase induction motor, take the

following precautions:

A. The motor losses are greater than for an inverter duty motor.

B. Avoid running the motor at low speed for a long time. Under this condition, the motor

temperature may rise above the motor rating due to limited airflow produced by the

motor’s fan. Consider external forced motor cooling.

C. When the standard motor operates at low speed for long time, the output load must be

decreased.

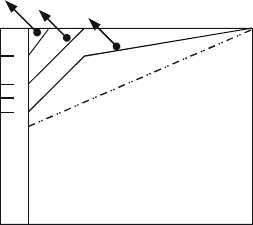

D. The load tolerance of a standard motor is as follows:

3 6 20 60

100

82

70

60

50

0

60%

40%

25%

torque(%)

continuous

Frequency (Hz)

Load duty-cycle

E. If 100% continuous torque is required at low speed, it may be necessary to use a special

inverter duty motor.