Network Device Product Manual

Table Of Contents

- Preface

- Table of Contents

- Chapter 1 Introduction

- Chapter 2 Installation and Wiring

- Chapter 3 Start Up

- Chapter 4 Digital Keypad Operation

- Chapter 5 Parameters

- 5.1 Summary of Parameter Settings

- Group 0 User Parameters

- Group 1 Basic Parameters

- Group 2 Operation Method Parameters

- Group 3 Output Function Parameters

- Group 4 Input Function Parameters

- Group 5 Multi-Step Speed and PLC Parameters

- Group 6 Protection Parameters

- Group 7 Motor Parameters

- Group 8 Special Parameters

- Group 9 Communication Parameters

- Group A PID Parameters

- 5.2 Parameter Settings for Applications

- 5.3 Description of Parameter Settings

- Group 0: User Parameters

- Group 1: Basic Parameters

- Group 2: Operation Method Parameters

- Group 3: Output Function Parameters

- Group 4: Input Function Parameters

- Group 5: Multi-step Speeds and PLC (Process Logic Control) Parameters

- Group 6: Protection Parameters

- Group 7: Motor Parameters

- Group 8: Special Parameters

- Group 9: Communication Parameters

- Group A: PID Control

- 5.1 Summary of Parameter Settings

- Chapter 6 Fault Code Information

- Chapter 7 Troubleshooting

- 7.1 Over Current (OC)

- 7.2 Ground Fault

- 7.3 Over Voltage (OV)

- 7.4 Low Voltage (Lv)

- 7.5 Over Heat (OH)

- 7.6 Overload

- 7.7 Keypad Display is Abnormal

- 7.8 Phase Loss (PHL)

- 7.9 Motor cannot Run

- 7.10 Motor Speed cannot be Changed

- 7.11 Motor Stalls during Acceleration

- 7.12 The Motor does not Run as Expected

- 7.13 Electromagnetic/Induction Noise

- 7.14 Environmental Condition

- 7.15 Affecting Other Machines

- Chapter 8 Maintenance and Inspections

- Appendix A Specifications

- Appendix B Accessories

- Appendix C How to Select the Right AC Motor Drive

Chapter 5 Parameters|VFD-S Series

Revision August 2008, SE09, SW V2.61 5-37

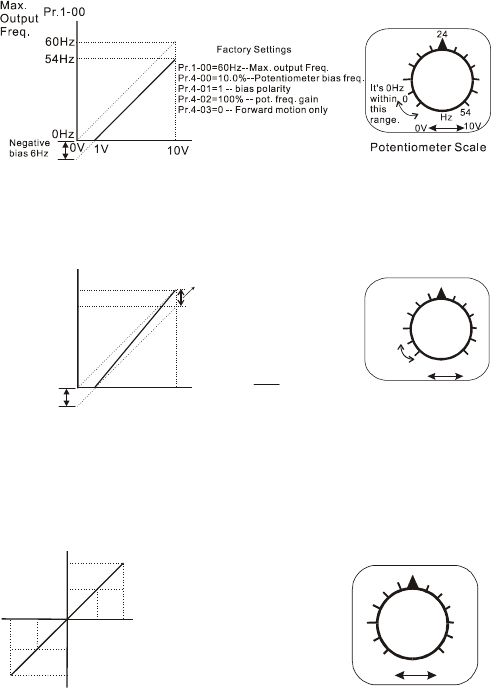

Example 6:

In this example, a negative bias is used to provide a noise margin. Also a potentiometer frequency

gain is used to allow the Maximum Output Frequency to be reached.

Hz

0V

10V

27

0

54

Potentiometer Scale

Max.

Output

Freq.

60Hz

Pr.1-00

0Hz

0V

10V

Factory Settings

Pr.1-00=60Hz--Max. output Freq.

Pr.4-00=10%--Potentiometer bias freq.

Pr.4-01=1 -- Bias polarity

Pr.4-02=111% -- Pot. freq. gain

Pr.4-03=0 -- Forward motion only

Negative

bias 6H

z

1V

It's 0Hz

within

this

range.

Gain adjustment

Calculation of gain

Pr.4-02=(

10V

9V

)X100%=111%

Example 7:

In this example, the potentiometer is programmed to run a motor is both forward and reverse

direction. A motor will be idle when the potentiometer position is at mid-point of its scale. Using

Pr.4-03 will disable the external FWD and REV controls.

Hz

0V

10V

0

60

Potentiometer Scale

Max.

Output

Freq.

Pr.1-00

Factory Settings

Pr.1-00=60Hz--Max. output Freq.

Pr.4-00=30Hz--Potentiometer bias freq.

Pr.4-01=1 -- bias polarity

Pr.4-02=200% -- pot. freq. gain

Pr.4-03=1 -- pot. REV motion enable

60Hz

30Hz

0Hz

0V

5V

10V

30Hz

60Hz

REV

FWD

REV.

FWD.

60

Example 8:

In this example, the option of anti-slope is shown. Anti-slope is used in an application where control

of pressure, temperature, or flow is needed. Under a high pressure or flow situation, a sensor will

generate a large signal such as 20 mA or 10V. With anti-slope enable, the large signal will slow or

stop the AC drive.