Specifications

Table Of Contents

- About This Manual

- 1.0 Introduction

- 2.0 Installation

- 3.0 Configuration Settings

- 4.0 Calibration

- 5.0 Scale Operations

- 5.1 Weight Unit Switching

- 5.2 Entering Tare Weights

- 5.2.1 One-Touch Tare, Tare Unknown

- 5.2.2 Digital Tare, Tare Weight Known

- 5.2.3 Tare Addition or Subtraction

- 5.2.4 Tare Exchange

- 5.3 Toggling Between Gross and Net

- 5.4 Entering Unit Weights

- 5.4.1 Unit Weight Operation by Sampling

- 5.4.2 Unit Weight Operation by Key Entry

- 5.5 Part Accumulation and Negative Counting - Without Recalling an Item Code

- 5.5.1 Part Accumulation

- 5.5.2 Negative Counting

- 5.5.3 Clearing Accumulated Data

- 5.6 Toggle Between Scales

- 5.7 Adding Parts To and Subtracting Parts From Inventory

- 5.7.1 Adding Parts to Inventory

- 5.7.2 Subtracting Parts From Inventory

- 5.7.3 Sample, Count and Print a Label

- 5.7.4 Scan ID Bar Code, Count and Print a Label

- 6.0 Scale Programming

- 6.1 Item Code Storage

- 6.1.1 Checking Memory Status

- 6.1.2 Program ID Code, Unit Weight, Tare Weight, Label Format, Part Name, Part Number, Lot Number, Location, Inventory Quantity, Threshold, and Setpoints

- 6.1.3 Delete Item Memory

- 6.2 Using Item Codes in Normal or Operation Mode

- 6.2.1 Recalling Numeric Item Codes using Item Code Number

- 6.2.2 Re-Computing Item Code Unit Weight

- 6.2.3 Quick Add Item to Memory

- 6.2.4 Tare Override

- 6.2.5 Inventory Operations Related to the Item Code Quantity

- 6.2.6 Delete Item Memory

- 6.3 Setting Tare in Operation Mode

- 6.3.1 One Touch Tare

- 6.3.2 Digital Tare (When Tare Weight is Known in Advance)

- 6.3.3 Tare Value Exchange (Tare Addition or Subtraction)

- 6.4 Setting a Lot Number

- 6.5 Setting a Sequence Number

- 7.0 External Printers, Barcode Scanners, Keyboards and Platforms

- 7.1 Connecting External Printers

- 7.1.1 SPEC Settings for External Printers

- 7.1.2 Connecting the Printer to the RS-232C Port

- 7.1.3 Eltron Printers

- 7.1.4 Epson Printers

- 7.2 Connecting a Barcode Scanner

- 7.2.1 Header Codes

- 7.2.2 Z Commands via Barcodes

- 7.2.3 Configuring the RS232C Port for a Scanner

- 7.2.4 Connecting the Scanner to the RS232C Port

- 7.2.5 Configuring the Keyboard Port for a Scanner

- 7.2.6 Programming the QSC-6000 Plus Quickscan RS232C Scanner

- 7.2.7 Programming the QuickScan Keyboard Wedge Scanner

- 7.3 Connecting the IBM Keyboard

- 7.4 Connecting an External Platform

- 8.0 Job Sequence Programming

- 9.0 Password Protecting the Programming Functions

- 10.0 DC-100 Error Message List

- 11.0 DC-100 Limited Warranty

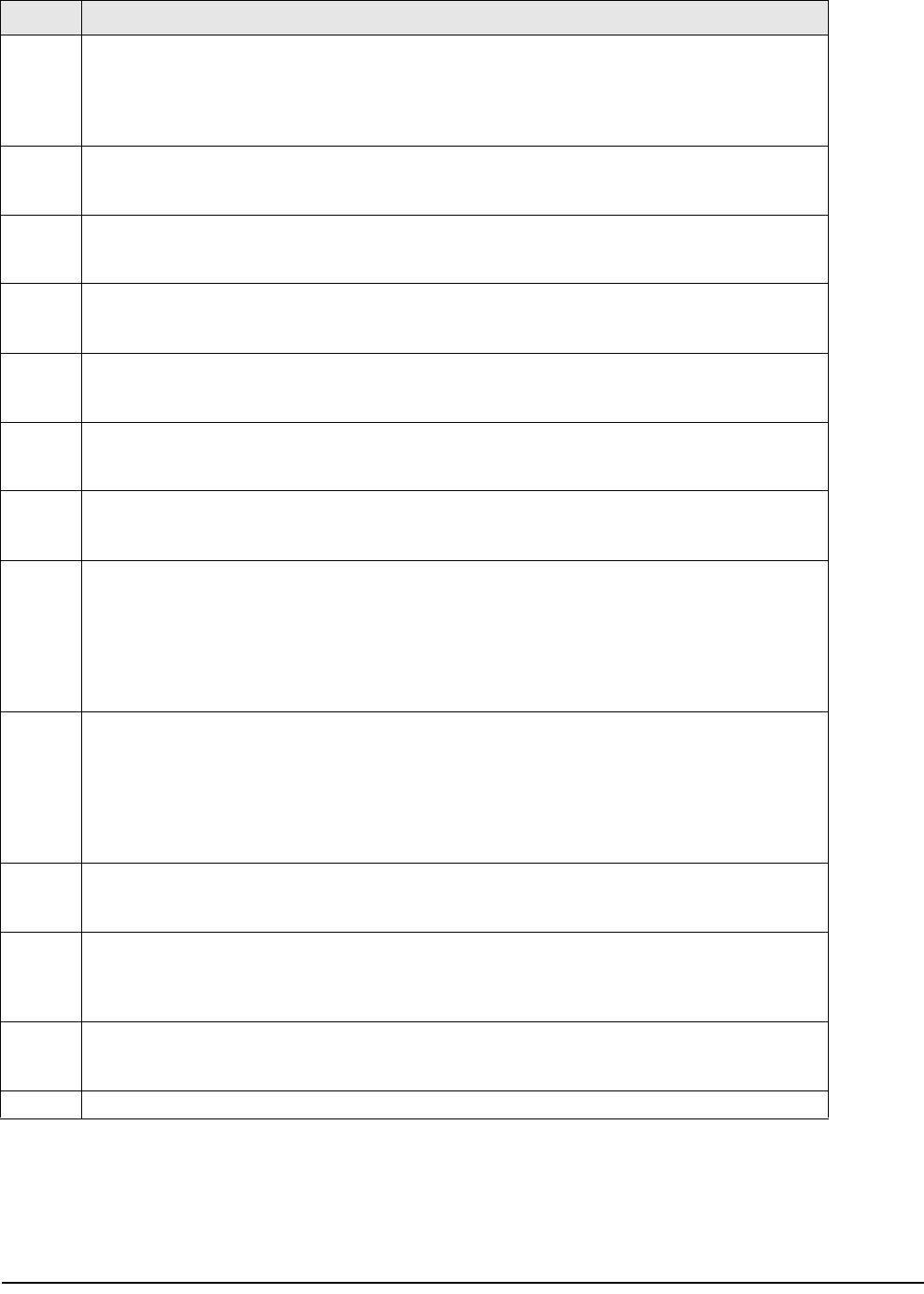

16 DC-100 Operation Manual

08 Sampling Times for Unit Weight Calculation

Higher number samples improve accuracy in environments of higher vibration or breeze but also

increase the time required to compute the unit weight.

0: 15 times (DEFAULT)

1: 20 times

09 Display Accuracy Unit Weight Calculation During Recomputing

0: No (DEFAULT)

1: Yes

10 Set Point Buzzer

0: Buzzer on (DEFAULT)

1: Buzzer off

11 Clear All Input Key in One Touch

0: Yes

1: No (DEFAULT)

12 Keep Lot Number in Registration (Operation) Mode

0: Allow (DEFAULT)

1: Inhibit

13 Job Sequence

0: Disable (DEFAULT)

1: Enable

14 Auto Exit From Add Mode

0: No

1: Yes (DEFAULT)

15 SIO Select Job

Defines what the primary or standard input/output port on the scale is connecting to.

0: No operation (DEFAULT)

1: Not Used

2: PC

3: Printer

4: Bar Code Scanner

16 RS-232C Baud Rate (SIO - Standard Input/Output Port)

0: 1200 baud

1: 2400 baud

2: 4800 baud

3: 9600 baud (DEFAULT)

4: 19200 baud

5: 38400 baud

17 RS-232C Data Length (SIO - Standard Input/Output Port)

0: 7 bits

1: 8 bits (DEFAULT)

18 RS-232C Parity Bit (SIO - Standard Input/Output Port)

0: None (DEFAULT)

1: Odd

2: Even

19 RS-232C Stop Bit (SIO - Standard Input/Output Port)

0: 1 bit (DEFAULT)

1: 2 bits

20-30 Specifications 20-30 are not used by the DC-100

SPEC Description

Table 3-1. DC-100 (141) Settings