Specifications

Table Of Contents

- About This Manual

- 1.0 Introduction

- 2.0 Installation

- 3.0 Configuration Settings

- 4.0 Calibration

- 5.0 Scale Operations

- 5.1 Weight Unit Switching

- 5.2 Entering Tare Weights

- 5.2.1 One-Touch Tare, Tare Unknown

- 5.2.2 Digital Tare, Tare Weight Known

- 5.2.3 Tare Addition or Subtraction

- 5.2.4 Tare Exchange

- 5.3 Toggling Between Gross and Net

- 5.4 Entering Unit Weights

- 5.4.1 Unit Weight Operation by Sampling

- 5.4.2 Unit Weight Operation by Key Entry

- 5.5 Part Accumulation and Negative Counting - Without Recalling an Item Code

- 5.5.1 Part Accumulation

- 5.5.2 Negative Counting

- 5.5.3 Clearing Accumulated Data

- 5.6 Toggle Between Scales

- 5.7 Adding Parts To and Subtracting Parts From Inventory

- 5.7.1 Adding Parts to Inventory

- 5.7.2 Subtracting Parts From Inventory

- 5.7.3 Sample, Count and Print a Label

- 5.7.4 Scan ID Bar Code, Count and Print a Label

- 6.0 Scale Programming

- 6.1 Item Code Storage

- 6.1.1 Checking Memory Status

- 6.1.2 Program ID Code, Unit Weight, Tare Weight, Label Format, Part Name, Part Number, Lot Number, Location, Inventory Quantity, Threshold, and Setpoints

- 6.1.3 Delete Item Memory

- 6.2 Using Item Codes in Normal or Operation Mode

- 6.2.1 Recalling Numeric Item Codes using Item Code Number

- 6.2.2 Re-Computing Item Code Unit Weight

- 6.2.3 Quick Add Item to Memory

- 6.2.4 Tare Override

- 6.2.5 Inventory Operations Related to the Item Code Quantity

- 6.2.6 Delete Item Memory

- 6.3 Setting Tare in Operation Mode

- 6.3.1 One Touch Tare

- 6.3.2 Digital Tare (When Tare Weight is Known in Advance)

- 6.3.3 Tare Value Exchange (Tare Addition or Subtraction)

- 6.4 Setting a Lot Number

- 6.5 Setting a Sequence Number

- 7.0 External Printers, Barcode Scanners, Keyboards and Platforms

- 7.1 Connecting External Printers

- 7.1.1 SPEC Settings for External Printers

- 7.1.2 Connecting the Printer to the RS-232C Port

- 7.1.3 Eltron Printers

- 7.1.4 Epson Printers

- 7.2 Connecting a Barcode Scanner

- 7.2.1 Header Codes

- 7.2.2 Z Commands via Barcodes

- 7.2.3 Configuring the RS232C Port for a Scanner

- 7.2.4 Connecting the Scanner to the RS232C Port

- 7.2.5 Configuring the Keyboard Port for a Scanner

- 7.2.6 Programming the QSC-6000 Plus Quickscan RS232C Scanner

- 7.2.7 Programming the QuickScan Keyboard Wedge Scanner

- 7.3 Connecting the IBM Keyboard

- 7.4 Connecting an External Platform

- 8.0 Job Sequence Programming

- 9.0 Password Protecting the Programming Functions

- 10.0 DC-100 Error Message List

- 11.0 DC-100 Limited Warranty

Calibration 25

4.0 Calibration

The DC-100 counting scale is a high-precision instrument. Although the scale needs very little maintenance, you

may want to check the calibration after every month or so of normal usage. To do this you will need to have a test

weight of approximately the total capacity of the scale (i.e. a 10 lb weight if you have a 10 lb capacity scale).

After the scale is initially installed, put the weight on the platform and record the weight displayed. Then every

month or so put the same weight on the scale and verify that it still reads the same.

Many facilities have a technician come in and check their units with certified test weights four times a year. If

you are ISO certified, you will want to check to see if your certification specifies more stringent requirements to

stay in compliance. Your DIGI scale dealer has the calibrated test weights, expertise and experience to perform

this task for you as well as to check other operating parameters of your scale and help you effectively integrate

scales into your operations. If you do not know who your local DIGI dealer is, call us at 1-715-736-0002 and we

will help you find someone who can provide you with on-site support.

Follow the instructions below to calibrate your DC-100 scale to ensure its continued accuracy.

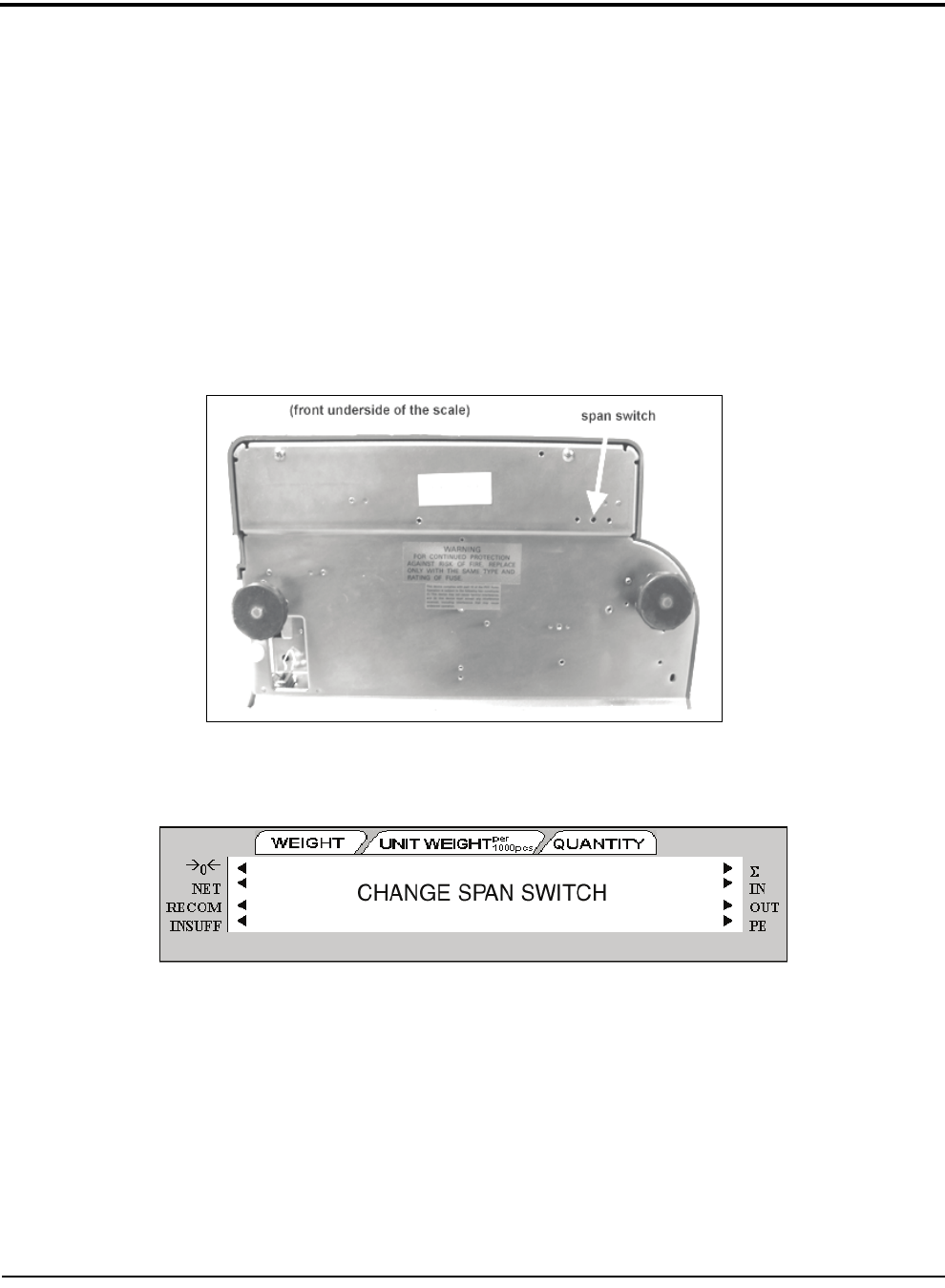

1. Make sure the scale is turned off. Then press the span switch to reset it. (See Figure 4-1 for location of

Span switch).

Figure 4-1. Location of Span Switch

2. Turn the scale back on. The scale displays the message CHANGE SPAN SWITCH.

3. While pressing the REZERO key, enter 8715 from the numeric keypad to enter the calibration mode.