User manual

Table Of Contents

- Zynq-7000 All Programmable SoC

- Table of Contents

- Ch. 1: Introduction

- Ch. 2: Signals, Interfaces, and Pins

- Ch. 3: Application Processing Unit

- Ch. 4: System Addresses

- Ch. 5: Interconnect

- Ch. 6: Boot and Configuration

- Ch. 7: Interrupts

- Ch. 8: Timers

- Ch. 9: DMA Controller

- Introduction

- Functional Description

- DMA Transfers on the AXI Interconnect

- AXI Transaction Considerations

- DMA Manager

- Multi-channel Data FIFO (MFIFO)

- Memory-to-Memory Transfers

- PL Peripheral AXI Transactions

- PL Peripheral Request Interface

- PL Peripheral - Length Managed by PL Peripheral

- PL Peripheral - Length Managed by DMAC

- Events and Interrupts

- Aborts

- Security

- IP Configuration Options

- Programming Guide for DMA Controller

- Programming Guide for DMA Engine

- Programming Restrictions

- System Functions

- I/O Interface

- Ch. 10: DDR Memory Controller

- Introduction

- AXI Memory Port Interface (DDRI)

- DDR Core and Transaction Scheduler (DDRC)

- DDRC Arbitration

- Controller PHY (DDRP)

- Initialization and Calibration

- DDR Clock Initialization

- DDR IOB Impedance Calibration

- DDR IOB Configuration

- DDR Controller Register Programming

- DRAM Reset and Initialization

- DRAM Input Impedance (ODT) Calibration

- DRAM Output Impedance (RON) Calibration

- DRAM Training

- Write Data Eye Adjustment

- Alternatives to Automatic DRAM Training

- DRAM Write Latency Restriction

- Register Overview

- Error Correction Code (ECC)

- Programming Model

- Ch. 11: Static Memory Controller

- Ch. 12: Quad-SPI Flash Controller

- Ch. 13: SD/SDIO Controller

- Ch. 14: General Purpose I/O (GPIO)

- Ch. 15: USB Host, Device, and OTG Controller

- Introduction

- Functional Description

- Programming Overview and Reference

- Device Mode Control

- Device Endpoint Data Structures

- Device Endpoint Packet Operational Model

- Device Endpoint Descriptor Reference

- Programming Guide for Device Controller

- Programming Guide for Device Endpoint Data Structures

- Host Mode Data Structures

- EHCI Implementation

- Host Data Structures Reference

- Programming Guide for Host Controller

- OTG Description and Reference

- System Functions

- I/O Interfaces

- Ch. 16: Gigabit Ethernet Controller

- Ch. 17: SPI Controller

- Ch. 18: CAN Controller

- Ch. 19: UART Controller

- Ch. 20: I2C Controller

- Ch. 21: Programmable Logic Description

- Ch. 22: Programmable Logic Design Guide

- Ch. 23: Programmable Logic Test and Debug

- Ch. 24: Power Management

- Ch. 25: Clocks

- Ch. 26: Reset System

- Ch. 27: JTAG and DAP Subsystem

- Ch. 28: System Test and Debug

- Ch. 29: On-Chip Memory (OCM)

- Ch. 30: XADC Interface

- Ch. 31: PCI Express

- Ch. 32: Device Secure Boot

- Appx. A: Additional Resources

- Appx. B: Register Details

- Overview

- Acronyms

- Module Summary

- AXI_HP Interface (AFI) (axi_hp)

- CAN Controller (can)

- DDR Memory Controller (ddrc)

- CoreSight Cross Trigger Interface (cti)

- Performance Monitor Unit (cortexa9_pmu)

- CoreSight Program Trace Macrocell (ptm)

- Debug Access Port (dap)

- CoreSight Embedded Trace Buffer (etb)

- PL Fabric Trace Monitor (ftm)

- CoreSight Trace Funnel (funnel)

- CoreSight Intstrumentation Trace Macrocell (itm)

- CoreSight Trace Packet Output (tpiu)

- Device Configuration Interface (devcfg)

- DMA Controller (dmac)

- Gigabit Ethernet Controller (GEM)

- General Purpose I/O (gpio)

- Interconnect QoS (qos301)

- NIC301 Address Region Control (nic301_addr_region_ctrl_registers)

- I2C Controller (IIC)

- L2 Cache (L2Cpl310)

- Application Processing Unit (mpcore)

- On-Chip Memory (ocm)

- Quad-SPI Flash Controller (qspi)

- SD Controller (sdio)

- System Level Control Registers (slcr)

- Static Memory Controller (pl353)

- SPI Controller (SPI)

- System Watchdog Timer (swdt)

- Triple Timer Counter (ttc)

- UART Controller (UART)

- USB Controller (usb)

Zynq-7000 AP SoC Technical Reference Manual www.xilinx.com 715

UG585 (v1.11) September 27, 2016

Chapter 27: JTAG and DAP Subsystem

27.4 Programming Model

27.4.1 Use Case I: Software Debug with Trace Port Enabled

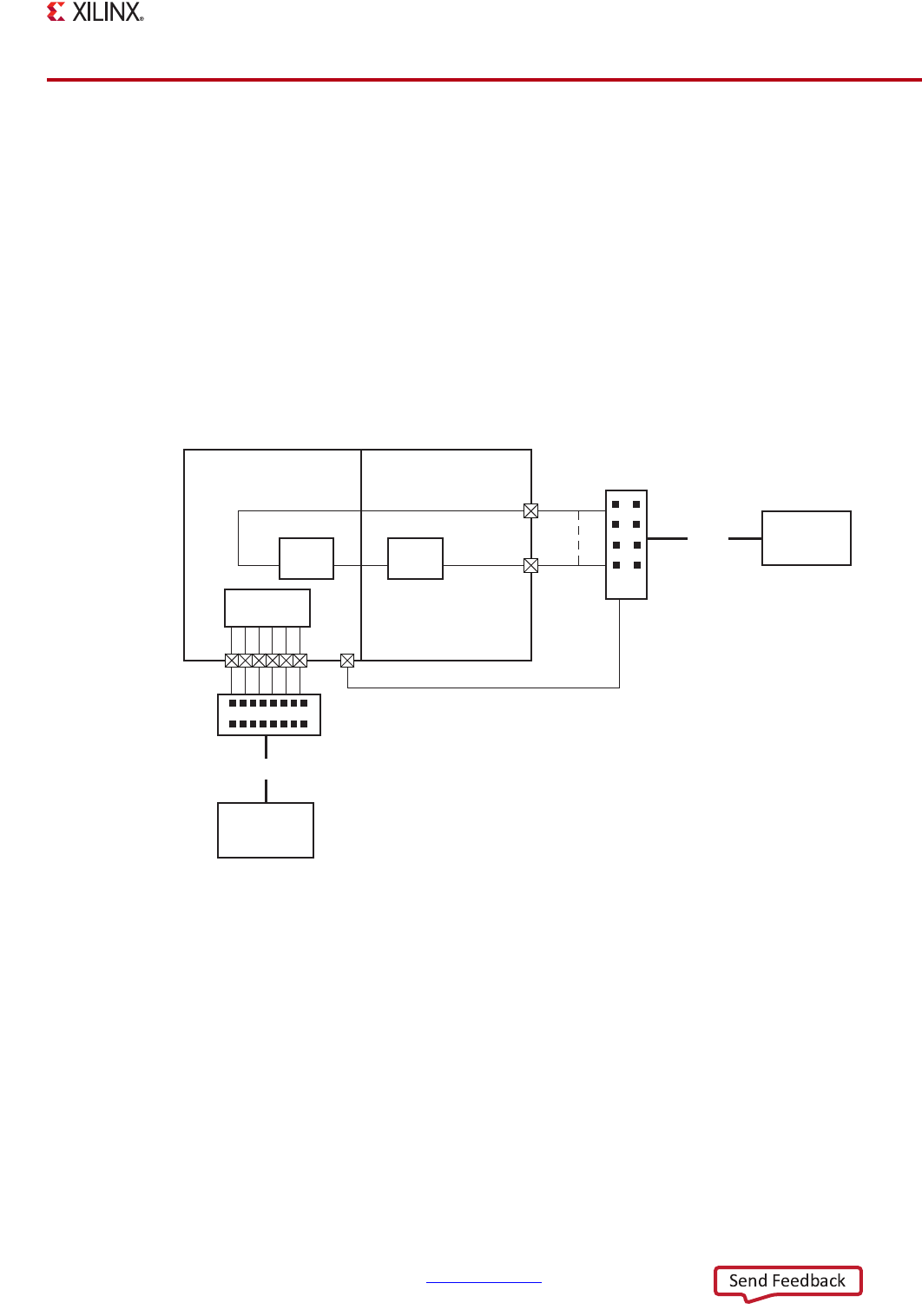

This is the normal debug case for most applications. Figure 27-4 shows ARM tool chain solution. It is

also possible to replace ARM Real View ICE with a Xilinx or Lauterbach debug tool. In this case, there

is no PL programming required and the user is able to start on software debug as soon as chip power

is on. In this use case, the DAP is active to support software debug needs but the TAP is put into

bypass mode. Trace port is also enabled through the MIO pin. Although bandwidth might be limited

due to limited MIO availability in some cases, the user could enable a trace dump without depending

on PL configuration in this configuration. The major challenge for most users is to allocate MIO pins

for the Trace port.

27.4.2 Use Case II: PS and PL Debug with Trace Port Enabled

The second use case shows how to enable PS software and PL hardware at the same time with two

separate debug tools. The tool connected to the Xilinx TAP is typically a Xilinx debug tool. The tools

connected to the PS DAP could be Xilinx or any third-party debug tools from ARM or Lauterbach.

To support this mode, PL configuration is required to bring the DAP JTAG signals to the PL SelectIOs.

Figure 27-5 shows trace port access through the PL SelectIO, but the user could use the MIO trace

port as in the previous use case if there is way to manage to fit the trace port into the limited MIO

pin multiplexing. Trace port access through SelectIO could support up to 32-bit trace data and gives

users enough trace port throughput to address most debug need. As with the JTAG DAP access, the

X-Ref Target - Figure 27-4

Figure 27-4: User Case I: Software Debug with Trace Port Enabled

DAP TAP

TPIU

JTAG

SS

SS

SRST

PS

PL

ARM

DStream

ARM Real

View ICE

UG585_c27_04_031812